Filament Non Woven Geotextile for Environmental Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description Of Filament Non Woven Geotextile:

It prevents the bank from being washed out, protects the bank and the bottom, prevents the water and soil from being washed away.

Main Features of Filament Non Woven Geotextile:

The filtration layer of the dykes, river canal, seacoast, concrete slope, retaining walls. At the same time of preventing the clay granule from passing, it allows the water and the gas pass through freely.

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

Specifications of Filament Non Woven Geotextile:

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the

airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different granule pathway from the groundsill or other buildings.

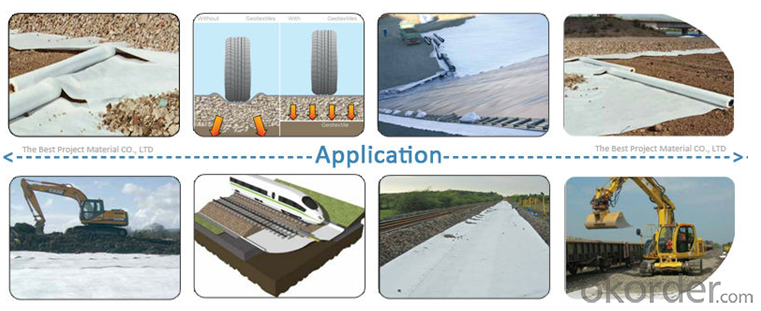

Applications of Filament Non Woven Geotextile:

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earth body stability.

IMages of Filament Non Woven Geotextile:

FAQ:

1. Do you supply free samples for customers?

Yes,we will supply free samples for you.Please send your address for us.

2. How Many years experience do you have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q:300g / m2 geotextile permeability coefficient is generally how much?

- Geotextile cloth short fiber geotextile and long fiber geotextile, the two geotextile permeability coefficient is basically the same. According to the requirements of the national standard 300g / ㎡ geotextile permeability coefficient for the K * (10 negative side ~ 10 negative three power), K is between 1.0-9.9 values. From the indicators can be seen 300g / ㎡ specifications of the geotextile has a good water filter, can be used for water, filter them.

- Q:Is the current tunnel construction, modular waterproof board (geotextile) is available?

- We use the soil is a geotech cloth waterproof board

- Q:How do geotextiles help with reinforcement of geogrids?

- Geotextiles help with the reinforcement of geogrids by providing a stable base and preventing soil erosion. They act as a separation layer between the geogrid and the soil, distributing the load evenly and increasing the overall strength and stability of the structure.

- Q:How do geotextiles help with siltation control in construction sites?

- Geotextiles help with siltation control in construction sites by acting as a barrier that prevents the movement of soil particles while still allowing water to pass through. They are typically placed on the ground surface or used as erosion control blankets, effectively reducing erosion and sediment runoff. This helps to minimize the amount of silt and sediment that enters nearby water bodies, maintaining water quality and protecting the surrounding environment.

- Q:Can geotextiles be used in railway construction?

- Yes, geotextiles can be used in railway construction. They are often used to separate and stabilize the underlying soil layers, provide drainage, and prevent the mixing of different soil types. Geotextiles also enhance the overall performance and longevity of the railway infrastructure by reducing soil erosion, mitigating the effects of frost heave, and improving load distribution.

- Q:What are the different design considerations for geotextile applications?

- Some of the key design considerations for geotextile applications include the type and quality of the geotextile material, the required strength and durability, the intended function (such as filtration, separation, reinforcement, or drainage), the site conditions and environmental factors, the installation and maintenance requirements, and the cost-effectiveness of the geotextile solution.

- Q:How do geotextiles help with sediment control?

- Geotextiles help with sediment control by acting as a barrier that prevents sediment from being washed away or eroded. They stabilize the soil, reduce erosion, and allow water to pass through while trapping sediment particles, thus preventing them from contaminating water bodies.

- Q:How do geotextiles contribute to pavement performance?

- Geotextiles contribute to pavement performance by providing reinforcement, filtration, and separation functions. They enhance the structural integrity of the pavement by distributing loads and reducing the potential for cracking and rutting. Geotextiles also help in preventing the mixing of different layers of pavement materials, improving drainage, and reducing the intrusion of fine particles into the pavement layers. Overall, geotextiles improve the durability, longevity, and overall performance of pavements.

- Q:What are the challenges associated with the installation of geotextiles?

- Some challenges associated with the installation of geotextiles include ensuring proper alignment and placement of the fabric, securing it to the ground to prevent shifting or movement, and properly overlapping and connecting multiple pieces of geotextile to create a continuous barrier. Other challenges may include dealing with uneven or unstable soil conditions, working in difficult terrain or access areas, and ensuring the geotextile does not get damaged during the installation process. Additionally, the selection and installation of appropriate anchoring methods and the need for specialized equipment or expertise can also pose challenges.

- Q:How do geotextiles help in stabilizing slopes?

- Geotextiles help in stabilizing slopes by providing reinforcement and erosion control. They are placed between soil layers to enhance their strength and prevent soil movement. Geotextiles act as a barrier, distributing the load over a wider area and reducing the risk of slope failure. Additionally, they promote drainage and filtration, preventing the accumulation of water that can weaken the soil and lead to erosion.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Filament Non Woven Geotextile for Environmental Protection

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords