F/R Double Side Reflective Aluminum Foil Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

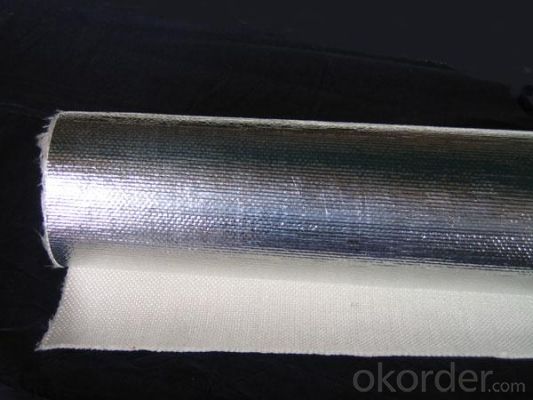

l Product Construction:

Composition | Description | Value (English) | Value (Metric) |

Foil | Aluminum | 0.28 mil | 7 micron |

Reinforcing - MD | Fiberglass | 2 / inch | 8 / 100mm |

Reinforcing - XD | Fiberglass | 3 / inch | 12 / 100mm |

Kraft | Natural | 49 lbs / 3000 ft2 | 80gsm |

Adhesive | Flame-Retardant Glue | ------ | ------ |

Foil | Aluminum | 0.28 mil | 7 micron |

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden

pallets, waterproof paper and plastic coverage or or

as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance

payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

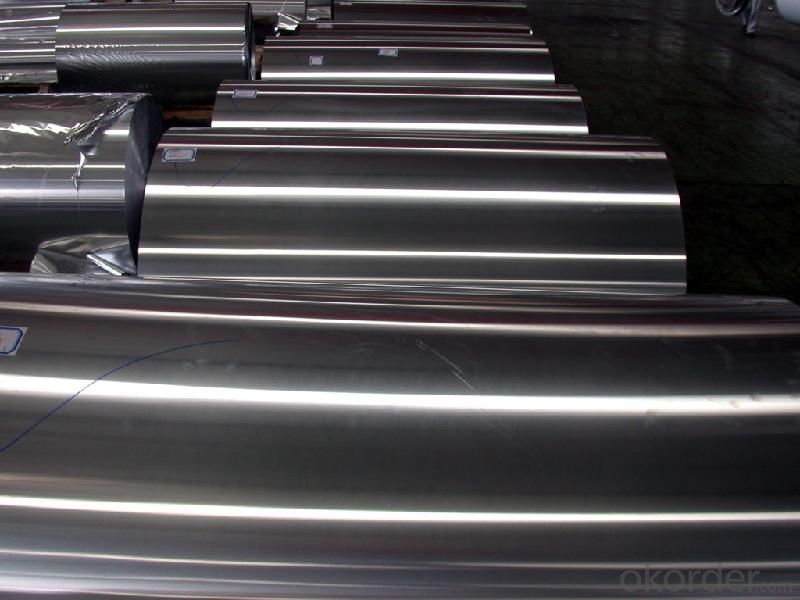

l Product Images

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 10 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email:service@okorder.com

- Q:How do aluminum coils contribute to energy efficiency in buildings?

- The use of aluminum coils is crucial for improving energy efficiency in buildings. To begin with, aluminum is an extremely conductive material, allowing for efficient heat transfer. This characteristic is particularly important in HVAC systems, where aluminum coils are commonly employed. These coils aid in the transfer of heat between the indoor and outdoor units, enabling effective temperature regulation and decreasing energy usage. Furthermore, aluminum coils are lightweight, making them easier to handle and install. This not only saves time and labor costs but also reduces the overall weight of the HVAC system, resulting in lower energy requirements for operation. Additionally, the lightweight nature of aluminum coils allows for the creation of compact systems, conserving valuable space in buildings. Additionally, aluminum is highly resistant to corrosion, ensuring the long-lasting and durable nature of the coils. This resistance to corrosion is especially vital in areas with high humidity or exposure to harsh weather conditions. By maintaining their effectiveness over time, aluminum coils minimize the need for frequent replacements, thereby reducing energy consumption associated with the manufacturing and installation processes. Another significant advantage of aluminum coils is their recyclability. Aluminum is one of the most widely recycled materials globally, with a high recycling rate and minimal loss of quality during the process. By utilizing aluminum coils, buildings contribute to a more sustainable and environmentally-friendly approach, as the material can be recycled repeatedly without compromising its performance. Moreover, the recycling process requires significantly less energy compared to primary aluminum production, resulting in reduced greenhouse gas emissions. In conclusion, aluminum coils play a crucial role in enhancing the energy efficiency of buildings through their high conductivity, lightweight nature, corrosion resistance, and recyclability. By facilitating efficient heat transfer, reducing energy consumption, and promoting sustainability, aluminum coils play a vital role in improving the energy efficiency of HVAC systems and overall building performance.

- Q:Are aluminum coils suitable for coil coating applications?

- Indeed, coil coating applications find aluminum coils to be a suitable option. Aluminum, owing to its outstanding resistance to corrosion, lightweight composition, and impressive strength-to-weight ratio, enjoys extensive usage in coil coating. Moreover, its high malleability facilitates effortless shaping and molding throughout the coil coating procedure. Furthermore, aluminum coils can be coated with an array of paints and coatings, offering a diverse selection of colors and finishes. To sum up, aluminum coils are a favored preference for coil coating applications due to their adaptability, longevity, and visually pleasing attributes.

- Q:Can aluminum coils be used in high-pressure applications?

- No, aluminum coils are not typically used in high-pressure applications due to their lower strength and less resistance to deformation compared to other materials such as steel.

- Q:What are the factors that affect the cost of aluminum coils?

- The cost of aluminum coils can be influenced by various factors. Firstly, the price of aluminum itself can fluctuate based on global supply and demand, as well as market conditions. These fluctuations directly impact the cost of aluminum coils. Secondly, the manufacturing process involved in producing aluminum coils plays a significant role in determining their cost. Different techniques, such as casting, rolling, and annealing, each have their own associated costs. The complexity and efficiency of the manufacturing process can directly affect the final price of the coils. Additionally, the size, thickness, and specifications of the coils can also impact their cost. Larger coils or those with specific dimensions may require extra raw materials, processing time, or specialized equipment, leading to higher costs. The type of surface finish applied to the coils is another factor that influences their price. Coils with higher-quality finishes, such as brushed or coated surfaces, require additional processing and materials, making them more expensive. Furthermore, the quantity and order volume of aluminum coils can affect their cost. Larger order quantities often result in economies of scale and lower unit costs. Conversely, smaller orders or customized specifications may incur additional setup costs or higher per-unit prices. The level of competition in the aluminum coil industry also plays a significant role in pricing. Increased competition among manufacturers can lead to more competitive prices as companies vie for customers. Conversely, limited suppliers or unique product offerings can drive prices higher due to reduced competition. Transportation and logistics costs are another factor to consider. The distance, mode of transportation, and fuel prices impact shipping costs, which can be passed on to customers. It is important to note that these factors are not exhaustive and may vary depending on specific circumstances and market dynamics. Additionally, external factors like taxes, tariffs, and government regulations can also influence the cost of aluminum coils.

- Q:Can aluminum coils be used for electrical transformers?

- Yes, aluminum coils can be used for electrical transformers. Aluminum is a suitable material for transformer coils due to its high electrical conductivity and lower cost compared to copper. While copper has traditionally been the preferred choice for transformer windings, the use of aluminum has gained popularity in recent years due to its lighter weight and lower price. Aluminum coils are also advantageous in terms of thermal conductivity, as they dissipate heat more efficiently than copper. However, it is important to consider the specific requirements and design considerations of the transformer, as the choice between aluminum and copper coils may depend on factors such as voltage, current, size, and insulation requirements.

- Q:What are the potential applications of brushed aluminum coils?

- Brushed aluminum coils have a wide range of potential applications across various industries. The distinct brushed finish of these coils makes them an attractive choice for both aesthetic and functional purposes. Here are some potential applications: 1. Architectural applications: Brushed aluminum coils can be used in architectural projects such as building facades, interior wall cladding, and decorative elements. The brushed finish adds a sleek and modern look, enhancing the overall design of the structure. 2. Automotive industry: Brushed aluminum coils can be used in the automotive industry for various purposes. They can be used for interior trim, such as dashboard panels, door handles, and decorative accents. The brushed finish adds a luxurious touch to the interior of vehicles. 3. Electronics and appliances: These coils can be used in the manufacturing of electronic devices and appliances. They are commonly used for the production of laptop casings, smartphone covers, and household appliances like refrigerators, ovens, and microwave panels. The brushed finish provides a stylish and durable surface. 4. Signage and displays: Brushed aluminum coils are often used in signage and display applications. They can be used for creating outdoor and indoor signs, channel letters, and exhibition displays. The brushed finish gives these signs a professional and eye-catching appearance. 5. Furniture and interior design: Brushed aluminum coils can be utilized in the furniture industry for various purposes. They are commonly used for creating furniture pieces like tables, chairs, and cabinets. The brushed finish adds a contemporary and sophisticated touch to the furniture design. 6. Packaging industry: Brushed aluminum coils can also find applications in the packaging industry. They can be used for packaging of high-end products like perfumes, cosmetics, and premium food items. The brushed finish gives the packaging a premium and luxurious appearance. 7. Industrial applications: These coils can be used in various industrial applications, such as manufacturing equipment, machinery, and industrial tools. The brushed finish provides durability, corrosion resistance, and a professional appearance. Overall, the potential applications of brushed aluminum coils are vast and diverse. From architecture to automotive, electronics to furniture, and packaging to industrial sectors, their versatility, durability, and aesthetic appeal make them a popular choice in multiple industries.

- Q:I am planning on calling an electrician before we move in. I was just wondering about some ballpark estimates to rewire a home with aluminum wiring (appx. 1900 sq feet).

- You may want to check with your insurance company, because my mom's house was wired up with alumimum wiring and now the house is about 30 years old and the insurance company is threating to drop the insurance if we don't replace the wiring with copper because alumimum will not take heavy electrical loads and when they do they heat up quickly and start fires. If you haven't bought the house i would put a clause into the buyer's agreement or ask for some money off because alumimum wires are infeior and garbage. For my mom's house it ended up costing us about 4000 bucks for the electrictian to pull out all the wires, we did the demo ourselves which was to pull all the drywall off and clean-up leaving all interior walls bare. and the rest of the 4000 was for the drywallers to come in and put new drywall up. But since our house also had old pipes too so we decieded to replace those too as well. What you may be looking at is a money pit, after all wiring, plumbing and other repairs were done, it ended up costing us about 12 grand to do all the work and half of it was because we did the work ourselves

- Q:Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are highly suitable for food and beverage packaging. Aluminum is a safe and durable material that helps protect the quality and freshness of food and beverages. It is non-toxic, corrosion-resistant, and provides an effective barrier against moisture, oxygen, and light. Additionally, aluminum coils are lightweight, easily moldable, and can be easily shaped into various packaging formats, making it a popular choice for the food and beverage industry.

- Q:my homework was to find out how do you get aluminium for rocks! I've been looking around but every web site i've been on only says that aluminium comes from rocks, but it doesn't say how you get it from rocks.e.g you get wool from sheep by shearing of their coat.so if anyone knows how you get aluminum from rocks please tell me i need your help.

- Well, you start with an aluminum rich rock (cheaper to process). The raw ore after physical concentration (removal of secondary minerals) is reacted by an electrolytic process. This means that electricity is used to convert the aluminum ion in the raw rock into the metal aluminum. Sort of like the reverse of a battery, to keep things simple. Aluminum smelters tend to be set up in places with cheap electricity, because the process uses a LOT of electricity. That is why there are several up here in quebec, we have cheap hydro electricity and the government gives decent deals to the smelters on top of the already low market price. Do a search on aluminum smelting to find out more. Not sure what your level of knowledge is so not sure how much you will understand.

- Q:Can aluminum coils be used in automotive applications?

- Automotive applications can indeed utilize aluminum coils. Given their lightweight nature, aluminum coils prove to be an exceptional option for automotive manufacturers, aiding in the reduction of overall vehicle weight. Consequently, this reduction can lead to enhanced fuel efficiency and performance. In addition, the outstanding heat conductivity of aluminum coils becomes indispensable in automotive applications, particularly when it comes to heat dissipation. Furthermore, the commendable corrosion resistance of aluminum coils proves to be highly advantageous in automotive applications, specifically when vehicles are exposed to diverse weather conditions and road salts. All in all, the utilization of aluminum coils in automotive applications offers numerous benefits, including weight reduction, improved fuel efficiency, superior heat dissipation, and enhanced corrosion resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

F/R Double Side Reflective Aluminum Foil Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords