Electro Galvanized Steel Wire

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

galvanized wire

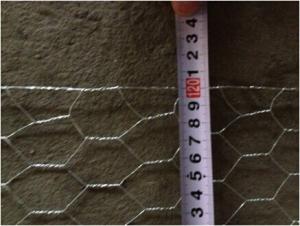

wire gauge:8--22#(other speccification can be made as customer's request).

type:electro galvanized wire and hot dipped galvanized wire.

material:Q195 Q235.SAE 1006/1008 ECT.

packing: 1--1000kg /coil (as customer's request).

application:this kind of wire is extensively used in construction binding wire woven mesh wire express way fencing mesh wire ect.

Galvanized wire's first stage is drawing.

there are two kinds of drawing machine: powder drawing and water drawing. powder drawing is fit for junior drawing(6.5mm~4.0mm). One powder drawing machine has 4 tanks and 4 molds. One tank is matched with a mold. Each of them are offered energy by a electromotor. 0.9mm(max)can be "eat" when the wire cross a mold. There are no loss of weight during drawing.

Galvanized wire's second stage is anneal.

Anneal is to low the tensile strength of wire. The stove is solid and built with red bricks. The architecture of anneal stove is cuboid. Different thickness of wire require different temperature. Range is from 700°C to 900°C. Output of the anneal stove, the tensile strength is 400N~600N.

Galvanized wire's third stage is chlorhydric acid washing.

After the draw and anneal, the wire is thinner, softer but also much more dirty. It needs chlorhydric acid washing to remove the impurities. Chlorhydric acid washing requires water pool and chlorhydric acid pool. The density of chlorhydric acid is 17%. In the Chlorhydric acid pool, there is a caldron used for the emission of vapor.

Galvanized wire's fourth stage: Zinc coating

After the chlorhydric acid pool, water pool is also necessary.

- Q:Is it possible to protect the radiation around the computer with a wire mesh?

- I have not heard of the wire, the chassis cover is the original radiation ah. Just do not advocate bare metal battle (no chassis or 24 hours cover)

- Q:Why do you want to shop a barbed wire?

- Barbed wire to determine a good fixed later, you can start plastering, of course, this step is also a measure of the degree of intentions of tileworkers, plaster live to do more detailed, the more flat the wall, the latter part of the possibility of the problem will be relatively small some.

- Q:How the wire is welded

- Only electricity, and electrode grinding replacement costs. Welding costs are much lower than welding.

- Q:How does the "jagged" on the back of the knife cut the barbed wire?

- Knife knife cutting barbed wire as shown: the knife hole slightly and the sheath of the protruding part of a combination on the line (to M86 Saber and AK Army knife, for example)

- Q:Will the gray sand brick wall is full of hanging wire mesh?

- Do not cover, mainly the block and concrete frame at the junction to hang 300mm wide steel wire mesh, barbed wire is in the bearing beam, column with the late brick between the wall of the nail,

- Q:What is the use of wire

- If the rust does not remove, this sponge-like rust is particularly easy to absorb moisture, iron is rotten faster

- Q:Wall tiles how to hang iron wire mesh

- Cold galvanizing process: cold galvanized is degreased, rusted, showing a dirty, penetrating welded wire mesh, hanging in the cathode of the special plating tank, galvanized anode. Connected to the DC power supply, the anode of the zinc ions migrate to the cathode and discharge on the cathode, so that the welding wire coated with a layer of zinc layer method;

- Q:Why is the effect of electromagnetic radiation shielding with wire mesh?

- Do not believe ah, this can drop, who also buy shielding materials ah; direct purchase of barbed wire on the line.

- Q:This material of the barbed wire in the water I do not know how long?

- Protection and shielding effect of the outermost layer of glue is insulated, the role of fire inside some iron / copper layer, is the protection and shielding effect of the innermost copper wire, is the current effect, used for conductive transmission

- Q:Is the warm tube laid on top of the steel wire or below?

- and that the road is broken, then the loop must be replaced by all the warm pipe, which means that your room layout of the road to warm all the area to all Out of all to replace the new pipe to replace.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Electro Galvanized Steel Wire

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords