E20 Emulsion E Glass Fiber Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 560 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E20 Emulsion Chopped Strand Mat

E20 Emulsion Chopped Strand Mat is made of randomly distributed chopped E6 glass strands held together by an emulsion binder. E20 is suitable to reinforce unsaturated polyester, vinyl ester,epoxy and phenolic resins.

E20 is designed mainly for use in the hand lay-up process and also suitable for use in filament winding and continuous laminating processes. Its end-use applications include boats, bath equipment, automotive parts, chemical corrosion resistant pipes, tanks, cooling towers and building components.

Product Features:

◎ Good conformability.

◎ Good wet-through and fast wet-out in resins, rapid air lease, reducing rolling out time and increasing productivity.

◎ Low resin consumption.

◎ High mechanical strength of parts.

◎ Superior acid corrosion resistance.

Product Specifications:

Property | Area Weight(g/m²) | Moisture Content(%) | Size Content(%) | Breakage Strength(N) |

Methods | ISO 3374 | ISO 3344 | ISO 1887 | ISO 3342 |

EMC225 | 225(1±6%) | ≤0.15 | 4.4(1±31%) | ≥80 |

EMC300 | 300(1±6%) | ≤0.15 | 4.0(1±31%) | ≥100 |

EMC375 | 375(1±6%) | ≤0.15 | 3.8(1±31%) | ≥120 |

EMC450 | 450(1±6%) | ≤0.15 | 3.7(1±31%) | ≥140 |

EMC600 | 600(1±6%) | ≤0.15 | 3.5(1±31%) | ≥160 |

EMC900 | 900(1±6%) | ≤0.15 | 3.3(1±31%) | ≥200 |

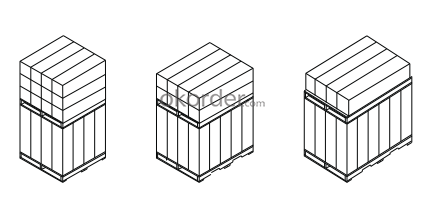

Packaging:

Each Emulsion Chopped Strand Mat is wound onto a paper tube which has an inside diameter of 90mm. The roll outside diameter is approximately 265mm. Each roll is wrapped up in plastic film and then packed in a cardboard box. The rolls are stacked horizontally or vertically onto pallets. All pallets are stretch wrapped and strapped to maintain stability during transport.

Storage:

Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture-proof area. The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at -10℃~35℃ and ≤80% respectively. It is best if the product is used within 6 months after production date.

- Q:Can fiberglass chopped strand be used for reinforcing ceramic matrix composites?

- Yes, fiberglass chopped strand can be used for reinforcing ceramic matrix composites. It provides strength and improved mechanical properties to the composite material.

- Q:How does the fiber orientation of fiberglass chopped strand affect the mechanical properties of composites?

- The mechanical properties of composites are greatly influenced by the fiber orientation of fiberglass chopped strand. Fiberglass chopped strand is made up of short individual fibers that are randomly oriented in various directions. When these chopped strands are added to a composite material, the fiber orientation becomes a crucial factor in determining the overall strength, stiffness, and other mechanical properties of the resulting composite. In general, a well-aligned fiber orientation within the composite can result in improved mechanical properties. When the fibers are aligned in the same direction as the applied load or stress, they can effectively transfer the load and resist deformation, thereby increasing the strength and stiffness of the composite. This alignment also enhances the load-bearing capacity of the composite material. Conversely, a random or less aligned fiber orientation can lead to decreased mechanical properties. Randomly oriented fibers may not distribute the applied load effectively, causing stress concentrations and potential failure points within the composite. This can result in reduced strength, stiffness, and overall performance. Additionally, the fiber orientation can also impact other mechanical properties such as impact resistance, fatigue resistance, and dimensional stability. Proper fiber alignment can enhance these properties, making the composite material more resistant to impacts, cyclic loading, and dimensional changes. In conclusion, the fiber orientation of fiberglass chopped strand has a significant impact on the mechanical properties of composites. A well-aligned fiber orientation can enhance strength, stiffness, impact resistance, fatigue resistance, and dimensional stability. Conversely, a random or less aligned fiber orientation can lead to reduced performance in these aspects. Therefore, careful consideration of fiber orientation is crucial in the design and manufacture of composites with desired mechanical properties.

- Q:What are the packaging options for fiberglass chopped strand?

- The packaging options for fiberglass chopped strand typically include bulk bags, cardboard boxes, and plastic bags.

- Q:Is fiberglass chopped strand UV resistant?

- Yes, fiberglass chopped strand is typically UV resistant. The UV resistance of fiberglass chopped strand is mainly attributed to the properties of the resin used to bind the strands together. Most resins used in fiberglass manufacturing, such as polyester or epoxy resins, have inherent UV resistance. Additionally, manufacturers often incorporate UV stabilizers into the resin formulation to enhance the UV resistance of the final product. This helps prevent the degradation of the fibers when exposed to sunlight or other sources of UV radiation. However, it is important to note that the level of UV resistance can vary depending on the specific resin formulation and manufacturing process. Therefore, it is recommended to consult with the manufacturer or supplier to ensure that the specific fiberglass chopped strand being used meets the required UV resistance specifications for the intended application.

- Q:How is fiberglass chopped strand packaged and shipped?

- Fiberglass chopped strand is typically packaged and shipped in various forms to ensure its safe transportation and handling. The packaging and shipping methods may vary depending on the manufacturer, customer requirements, and the specific type of fiberglass chopped strand being shipped. One common packaging method is to pack the chopped strand into cardboard boxes or plastic bags. The chopped strand is carefully placed and compressed into these packages to maximize the quantity per package and minimize the risk of damage during transit. These boxes or bags are then sealed to secure the contents and prevent any moisture or contaminants from entering. In some cases, fiberglass chopped strand may also be packaged in bulk bags or super sacks. These large bags are made from durable polypropylene material and can hold a significant amount of chopped strand, typically ranging from hundreds to thousands of pounds. Bulk bags often have lifting loops or straps attached to facilitate handling and loading onto pallets or trucks. Once packaged, fiberglass chopped strand is loaded onto pallets for shipment. The pallets are typically made of wood or plastic and are designed to provide stability and protection during transportation. The packages or bulk bags are securely strapped or shrink-wrapped to the pallets to prevent any movement or damage during transit. Shipping methods for fiberglass chopped strand can vary depending on the distance and destination. For shorter distances, the palletized packages or bulk bags may be transported using trucks or vans. For longer distances or international shipments, the chopped strand may be loaded into shipping containers and transported by sea or air freight. To ensure safe and intact delivery, fiberglass chopped strand may also be secured with additional protective measures such as stretch wrapping, corner protectors, or cushioning materials to minimize the risk of damage caused by vibrations or impacts during transit. Overall, the packaging and shipping of fiberglass chopped strand are crucial to maintain the structural integrity and quality of the product, as well as to ensure safe handling and transportation from the manufacturer to the customer.

- Q:Can fiberglass chopped strand be used for reinforcing polymer matrix composites?

- Yes, fiberglass chopped strand can be used for reinforcing polymer matrix composites. Fiberglass chopped strand consists of short lengths of fiberglass strands that are randomly oriented. These chopped strands are mixed with a polymer matrix, such as epoxy, polyester, or vinyl ester resin, to create a composite material. The fiberglass chopped strand provides reinforcement to the polymer matrix by improving strength, stiffness, and impact resistance. The orientation of the chopped strands helps distribute the load evenly throughout the composite, making it stronger and more durable. Furthermore, the use of fiberglass chopped strand in polymer matrix composites offers several advantages. It is lightweight, corrosion-resistant, and has excellent electrical insulation properties. It also provides good dimensional stability and can be easily molded into complex shapes. Overall, fiberglass chopped strand is an effective and commonly used reinforcement material for polymer matrix composites, making it suitable for various applications such as automotive parts, aerospace components, construction materials, and consumer products.

- Q:What is the average diameter of fiberglass chopped strand?

- The average diameter of fiberglass chopped strand typically ranges from 10 to 25 micrometers. However, it is important to note that the specific diameter can vary depending on the manufacturer and specific product type.

- Q:Can fiberglass chopped strand be used for sound insulation?

- Yes, fiberglass chopped strand can be used for sound insulation. The irregular fibers of fiberglass help to absorb sound waves, reducing noise transmission and improving acoustics in various applications.

- Q:How does the density of chopped strand composites compare to other materials?

- The density of chopped strand composites typically falls in the middle range when compared to other materials. It is generally lighter than metals such as steel or aluminum, but heavier than materials like foams or plastics.

- Q:How does the moisture absorption of fiberglass chopped strand affect its performance?

- The performance of fiberglass chopped strand can be significantly affected by its ability to absorb moisture. Fiberglass is renowned for its exceptional strength and durability, making it a popular choice across multiple industries such as automotive, aerospace, construction, and marine. However, when fiberglass comes into contact with moisture, it undergoes a process known as hydrolysis, which weakens its structural integrity. When water or high humidity environments come into contact with fiberglass chopped strand, moisture absorption occurs. The water molecules penetrate the surface of the fiberglass and react with the resin matrix that binds the strands together. This reaction causes the resin to deteriorate, resulting in a decrease in the material's mechanical properties, including strength, stiffness, and dimensional stability. Moisture in fiberglass chopped strand also provides a conducive environment for the growth of mold, mildew, and other fungi. These microorganisms further degrade the material, causing discoloration, unpleasant odors, and potential structural damage. Moreover, the weight gain caused by moisture absorption can negatively impact the fiberglass's weight-to-strength ratio, reducing its efficiency in applications where weight reduction is crucial. Additionally, moisture absorption alters the thermal and electrical conductivity of fiberglass chopped strand. As water is an excellent conductor of heat and electricity, the presence of moisture increases the material's thermal and electrical conductivity, which may not be desirable in certain applications. To mitigate the adverse effects of moisture absorption, various measures can be implemented. One common approach is applying protective coatings or treatments to the fiberglass surface, creating a barrier against water penetration. Additionally, using hydrophobic or moisture-resistant resins during the manufacturing process helps minimize the rate of moisture absorption. In conclusion, moisture absorption significantly impacts the performance of fiberglass chopped strand. It diminishes mechanical properties, fosters the growth of microorganisms, increases weight, and alters thermal and electrical conductivity. Implementing appropriate measures to minimize moisture absorption is crucial to ensure optimal performance and longevity in various applications of fiberglass chopped strand.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

E20 Emulsion E Glass Fiber Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 560 kg

- Supply Capability:

- 10000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords