Ductile Iron Pipe EN598 DN250 Class K9

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Ductile Iron Pipe Description :

DI pipe fittings are manufactured according to ISO 2531 or BS EN545 or BS4772 FOR POTABLE WATER ,internal is cement lining or wet epoxy coating;External is zinc plus bitumen or wet epoxy coating. We also manufacture ductile iron fittings with fusion bonded epoxy both inside and outside. All the producets are sutible to water pipes fields.

We have passed ISO9001,ISO14001,OHSMS18001 certificate.

2,Main Features of the Ductile Iron Pipe:

1).Quality guarantee

• Chemical checking

• NDE after rough machining

• Mechanical testing after heat treatment

• Final NDE,dimension inspected

2).Quality document

• Full Q.A document as per client request

3).Packing and Shipping

• standard export package(carton/wooden case/pallet)

• accept FOB,FAS,CNF,CIF door to door etc or customer designated shipping agent

4).Service

• Drawing: we can translate your original drawing, offer best suggestion on design

• Quality: we have full set quality control system to guarantee the best quality.

• Inspection: inspect in house, all our products must be checked 3 times before packing

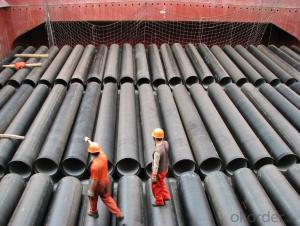

3,Ductile Iron Pipe Images:

4.Ductile Iron Pipe Specification:

Surface Finishes: Bare, Oiled, Mill Varnish, Galv,FBE, FBE Dual, 3LPE, 3LPP, Coal Tar,Concrete Coating and Tape Wrap

End Finishes: Beveled, Square Cut, Threaded, hat

Additional Services: Internal Coating

Packaging: packed in bag, plastic bag, steel strip, steel wire,double wire, iron box, wooden box, tarpaulin, plastic sheeting

Inspection: MOODY SGS BV GL DNV ABS LIOYD’S

Test: X-ray, UT, magnetic particle,inspection,hydrostatic test.

Processing service: Beveling, Threading, Slotting, Cut-to length, Bends, Quench and Temper, Fabrication, Double-jointing and On-site assistance

Documentary: MTC, material certification,Origin certification, CI or PI,Test Report, export licence, handling order, B/L,insurance policy,shipping instructions, contract, packing list etc.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

1.Q: Why would you choose ductile iron pipe rather than other pipe materials?

A:The reasons are obvious for that not only ductile iron pipe possesses the inherent strength and flexibility of ductile iron, combined with proven corrosion protection systems, but also the cost savings can be achieved from design to installation and commissioning.

2.Q:Why can you guarantee the inner of pipes can’t be corroded?

A: High alumina cement mortar lining and sulphate-resistant cement mortar lining. These two special linings are applicable to inner anti-corrosion for sewage pipes, improving resistance to erosion of the sewage components.

- Q:What is the cost of ductile iron pipe compared to other pipe materials?

- The cost of ductile iron pipe is generally higher compared to other pipe materials such as PVC or steel due to its superior durability and strength.

- Q:What is the difference between spheroidal graphite cast iron QT400-15 and QT400-15A? What does the A mean later?

- The front is the material grade, and the back of the A should have special requirements.

- Q:Can ductile iron pipes be used in geothermal systems?

- Ductile iron pipes are indeed suitable for geothermal systems. Their renowned strength and durability make them an excellent choice for various applications, including geothermal systems. These systems involve extracting heat from beneath the earth's surface, necessitating a dependable and robust piping system to transport the geothermal fluid. Ductile iron pipes can withstand high temperatures and pressures, making them perfect for carrying hot geothermal fluids. Moreover, they exhibit exceptional corrosion resistance, a crucial attribute for geothermal systems that often involve the circulation of corrosive fluids. In conclusion, ductile iron pipes provide a reliable option for geothermal systems due to their strength, durability, and ability to withstand high temperatures and corrosion.

- Q:What are the different methods for restraining ductile iron pipe?

- Some different methods for restraining ductile iron pipe include using thrust blocks, tie rods, and flexible couplings. Thrust blocks are concrete structures that are placed at bends or fittings in the pipeline to resist the axial thrust forces. Tie rods are used to connect the pipe to fixed points, providing additional support and preventing movement. Flexible couplings can also be used to restrain pipe by connecting sections together, allowing for some movement while still maintaining stability.

- Q:Are ductile iron pipes suitable for use in cooling water systems?

- Ductile iron pipes are indeed appropriate for utilization in cooling water systems. They exhibit remarkable strength and durability, rendering them impervious to the intense pressure and corrosive properties inherent in such systems. Furthermore, they possess the ability to withstand extreme fluctuations in temperature while delivering enduring performance. Additionally, ductile iron pipes exhibit commendable resistance to the proliferation of microorganisms, a crucial aspect in preserving the quality of the cooling water. Moreover, these pipes facilitate effortless installation and necessitate minimal maintenance, thereby constituting a cost-effective alternative for cooling water systems. In summary, ductile iron pipes represent a dependable and suitable choice for employment in cooling water systems.

- Q:Can ductile iron pipe be used for hydropower systems?

- Ductile iron pipe is perfectly suitable for hydropower systems. It is renowned for its robustness, longevity, and ability to resist corrosion, making it an excellent option for numerous applications, including hydropower systems. The remarkable tensile strength of ductile iron enables it to endure the immense pressure and heavy loads associated with such systems. Additionally, its resistance to corrosion makes it ideal for use in water environments, ensuring a lengthy lifespan and minimal maintenance requirements. Consequently, ductile iron pipe can effectively serve hydropower systems by offering a dependable and efficient solution for water transportation and infrastructure support.

- Q:Can ductile iron pipes be used for rainwater harvesting systems?

- Yes, ductile iron pipes can be used for rainwater harvesting systems. Ductile iron pipes are known for their durability and strength, making them suitable for various applications, including rainwater collection and storage. They can effectively transport rainwater from collection points to storage tanks, ensuring a reliable and efficient rainwater harvesting system.

- Q:What is the maximum temperature that ductile iron pipe can handle?

- The ability of ductile iron pipe to withstand high temperatures varies depending on factors such as the grade of ductile iron, the length of time exposed to heat, and the presence of external factors like corrosive environments. In general, ductile iron pipes can tolerate temperatures up to 400-450 degrees Fahrenheit (204-232 degrees Celsius) for short periods. However, it is crucial to refer to the manufacturer's specifications and guidelines to determine the exact maximum temperature limits for a specific grade of ductile iron pipe. Additionally, it is advisable to consider the consequences of thermal expansion, potential loss of mechanical properties, and any additional protective measures that may be necessary when operating at elevated temperatures.

- Q:What are the typical installation methods for ductile iron pipe?

- The typical installation methods for ductile iron pipe include trenching, horizontal directional drilling, and jacking. In trenching, a trench is excavated and the pipe is laid and supported on a bed of aggregate. Horizontal directional drilling involves drilling a pilot hole underground and then pulling the pipe through the hole. Jacking is a method where the pipe is pushed into the ground using hydraulic jacks.

- Q:How does the white iron appear in the case of ductile iron?

- The addition of 0.2% SiC in the raw iron water can effectively reduce the chill.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Ductile Iron Pipe EN598 DN250 Class K9

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords