Drywall Sound Absorption Gypsum Ceiling Tiles600*600

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

* Material: Atlantis paper-faced gypsum board

* Thickness: 7mm, 7.5mm, 8.0mm, 8.5mm, 9.0mm, 9.5mm, 12mm, 12.5mm

* Sizes: 595x595mm, 600x600mm, 595x1195mm, 603x603mm, 605x605mm,603x1212mm, 610x1220mm(2’x 4’)

* Size tolerance: length<±2mm, width<±2mm, thickness<±0.5mm< p="">

* Weight:7mm=5.5kg/sqm, 7.5mm=5.7kg/sqm, 8.0mm=5.9kg/sqm, 8.5mm=6.2kg/sqm, 9mm=6.8kg/sqm, 9.5mm=7.1kg/sqm, 12mm=9.2kg/sqm, 12.5mm=9.5kg./sqm

* Strength: >160N

* Characters: non-flammable B1, in accordance with Chinese standard GB8624-1997

* Installation: match with ceiling T-bar

* Strength: >160N

* Characters: non-flammable B1, in accordance with Chinese standard GB8624-1997

* Installation: match with ceiling T-bar

* Strength: >160N

* Characters: non-flammable B1, in accordance with Chinese standard GB8624-1997

* Installation: match with ceiling T-bar

Product Advantages:

1) Material: Germany Quality gypsum board,Imported high quality PVC and aluminum foil.

2) Thickness: 7mm, 7.5mm,8mm, 9mm, 9.5mm, 12mm.

3) Sizes: 595 x 595mm, 595 x 1195mm, 603 x 603mm, 603 x1212mm,2'x2,2'x4',600x600mm,600x1200mm.

4) Size tolerance: Length < 1mm, width < 1mm, thickness < 0.2mm

5) Weight: 7.6kg/sqm

6) Strength: >160N

7) Characters: Non-flammable B1, in accordance with China standard GB8624-1997

8) Installation: Match with ceiling T grid.

Main Product Features:

Standard size: 1220*2440mm 1200*600mm 603*603mm 595*595mm

thickness control: 3-30mm

Physcial property(reference only)

100% non-asbestos

Density: 0.9-1.3g/cm3

Moisture content: <=10%

Thermal conductivity:<=0.23W/MK

Asbestos content: 100% non-asbestos

Radioactivity: comply with GB6566-2001 A Class

Fire resistance: no chapping and slip cracking occur after 25times of frost-melting

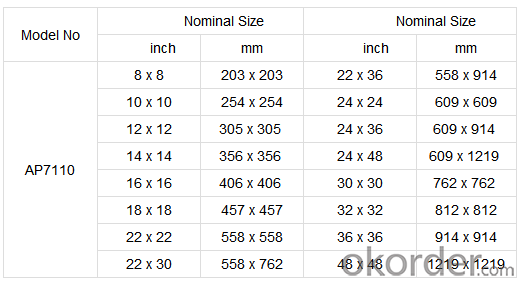

Product Specifications:

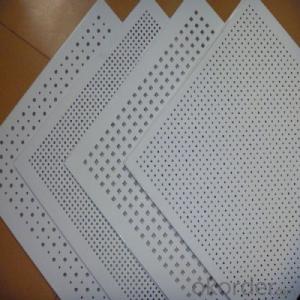

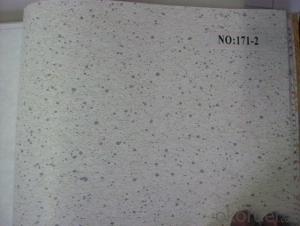

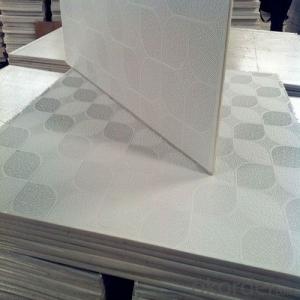

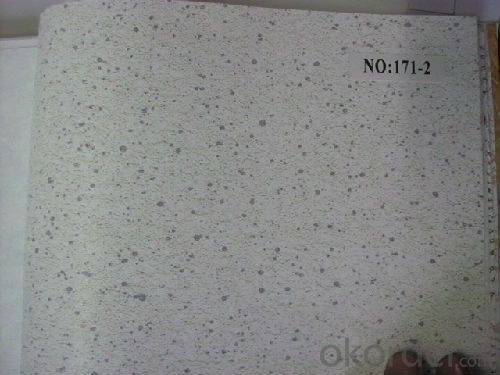

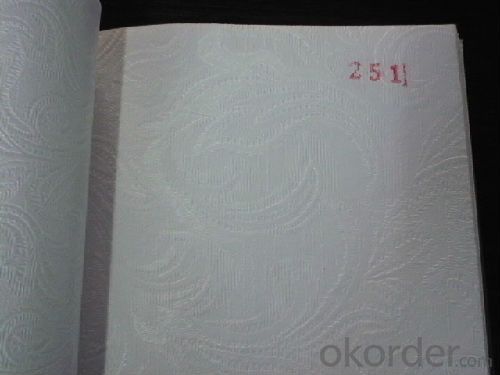

Images:

- Q:Gypsum board linear ceiling, L-type linear ceiling what is the difference

- L-type is a simple straight or back to the type of ceiling, suitable for simple decoration style. Gypsum board straight ceiling ceiling is usually 600 * 600, with a protruding pattern, with 38 main bone and T bone assembly.

- Q:Living room with gypsum board ceiling, a few lights, gypsum board to use how wide, high from the ceiling?

- The bottom of the installation of downlights, the number of installed, according to the length of the living room wall to determine the general distance between the lamp and the lamp in about 1 meter, according to the actual situation to determine the number of installed lights and spacing, not necessarily to install How many lights are.

- Q:What are the advantages and disadvantages of the fir board?

- Fir board although the price is low but the quality is not good, it is best not to use, the balcony area is more sunny area. In the long-term sunlight, the fir board is easy to crack.

- Q:Gypsum board ceiling, need to use long self-tapping nail?

- Monolithic gypsum board (9.5mm or 12mm) with 25mm anti-rust self-tapping screws can be; double gypsum board with 35mm anti-rust self-tapping screws can; other circumstances according to the scene to set.

- Q:Living room size length 5.2 wide 3.5 high 2.75 ceiling width should be designed to be somewhat beautiful? What is the distance from the ceiling to the ceiling? Is the kind of buckle groove, what materials before the production? Do not paint it?

- Woodworking materials: ??? Wood studs (nails and anti-corrosion site production), blockboard (shaped ceiling), paper gypsum board, nails, steel row nails, gas row nails, tapping screws, foaming agent, white latex, preservatives Most of the home decoration) and so on.

- Q:Ready to do at home to do the ceiling, the top of the wire how to go, what kind of need to use the wire, how fixed line, how to build the line, please introduce some of the details

- 1.5-2.5 square plastic line, PVC lock mother, lamp box, 16 # PVC pipe. Fixed pipe with a nylon cable ties, or tied with a tie bar tied to the keel on it, the ceiling space is small, the lamp box to deviate from the installation location of the lamp, or else the installation of the lamp is not enough height to the lamp box to the lamp lead line can be plastic Threaded pipe or 12 # yellow wax tube.

- Q:Some people say that the seam is really good cloth with kraft paper is good, is that so?

- If there is a fixed point in the YKB board hole, there are two ways to deal with: ??????? (1) Re-punch in the appropriate space around it. (2) with 50X50 iron thickness 3-4mm nut tightening spot welding.

- Q:The distance between the curtains of the Roman rod and the ceiling or gypsum line should be appropriate?

- The top hole is 6 cm distance, the premise is that your curtains are done to the floor

- Q:Mineral wool board: seventy / square meter, light industry: twenty / square meter.

- Gypsum board flat top: one hundred three / square meter, light industry: twenty - five / square meter.

- Q:Gypsum board ceiling scraping putty treatment and preparation work

- Work: 1, wall treatment of the scraping putty The general wall scraping 2 putty can be, the flatness of the wall requires a lot of local scraping several times, more serious need to find plaster leveling, each putty scraping need to be more than 2 hours. 2, repair the wall to deal with the putty polished After the putty scraping, polished, you can at night, with more than 200 watts of light bulb close to the wall, while grinding side view flatness. Polished easy to produce a lot of dust, need to do a good job wearing masks and so on. 3, the decoration of the wall to deal with the brush primer The dust on the wall putty putty clean, the primer evenly brushing, waiting for the primer dry. 4, repair the wall to deal with the brush finish Under normal circumstances, the topcoat usually need to brush twice, the first pass to wait for its drying only need 2-4 hours. The second time it takes 1-2 days after the job.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Drywall Sound Absorption Gypsum Ceiling Tiles600*600

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords