Dioctyl Phthalate (DOP) alternative DEDB for PVC Plasticizer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product performance:

Polyol Benzoate (DEDB) is colorless or pale yellow transparent oily liquid, water-insoluble, soluble in aromatic hydrocarbons, ketones and ethers, and has good compatibility withpolyvinyl chloride, ethylene - vinyl acetate copolymer, poly vinyl acetate, polymethylmethacrylate, polyvinylbutyral, nitrocellulose, and ethyl cellulose, etc.

Product application:

Polyol Benzoate(DEDB) is an environmentally friendly plasticizer with the characteristics of strong solubility, good compatibility, low volatility,resistant to oil, water, light, pollution etc. It is suitable for processing PVC flooring material, plastisol, artificial leather, cable material, soft and hard pipe, shoes material, rubber strips, synthetic rubber, and paint, printing ink, etc. It has a better plasticized effect if it is used together withDOP or DBP, and has greatly achieved the purpose of reducing cost .

Product quality index

Item | First grade | Second grade |

Chroma(APHA) ≤ | 50 | 60 |

Ester % ≥ | 99.5 | 90.0 |

Density(20°C)g/ | 1.120-1.126 | 1.172-1.78 |

Acidity(as benzene dicarbonic acid) % ≤ | 0.01 | 0.02 |

Flash Point °C ≥ | 195 | 192 |

Loss on heat(125°C,2 hours)% ≤ | 0.3 | 0.5 |

Chroma after heat treatment | 80 | 100 |

Specifications

1. Direct producer with 15 years experience

2. ISO9001:2000

3. High quality, lower price and best service

4. New plasticizer

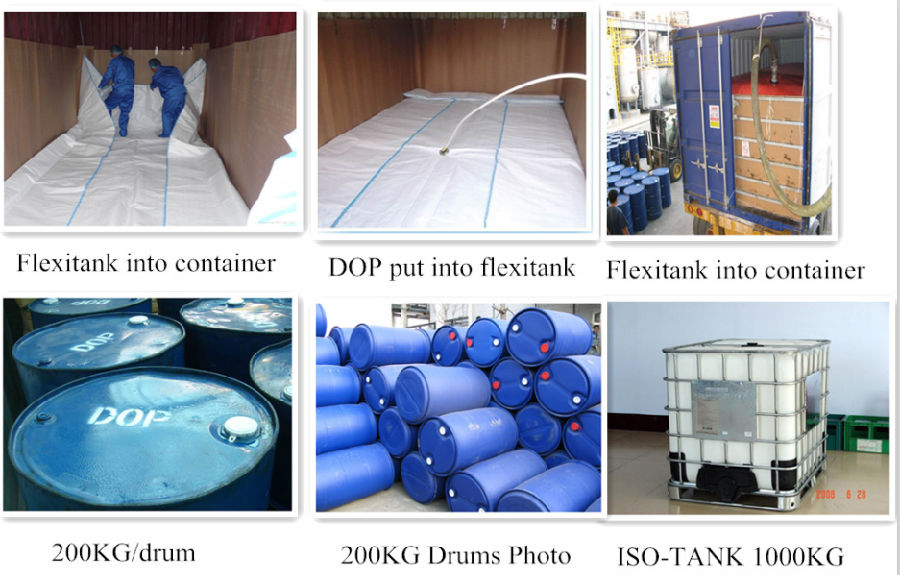

Packaging: IBM, net weight: 1000 kg.

Our Factory:

Our Factory:

- Q:Why the catalyst after the chemical reaction of its quality and chemical properties unchanged

- In fact, the catalyst reaction also enters, which changes the rate of positive and negative reactions ... enhances the reactive molecules of the reactants, thereby changing the reaction rate ...

- Q:Chemical catalyst system baa?

- Catalyst is divided into inorganic catalyst and organic catalyst organic reaction generally need more catalyst, such as concentrated sulfuric acid

- Q:Also, how is the catalyst affected by heat? Please answer all of the questions not just one of the three. THANK YOU!

- The catalyst is affected by vinegar because vinegar is acidic meaning there are more H+ ions. This alters the charges on the R groups of the amino acid residues of the enzyme molecule. The bonds that help maintain the conformation of the enzyme molecule which is ionic will therefore, be disrupted and the binding of substrate will be affected. However, if pH is restored to optimum pH, the maximum activity of the enzyme will be restored but this is only if the pH was only altered by a small extent. If pH is altered by a large extent, the conformation of the enzyme molecule will be severely affected causing it to denature. The catalyst is affected by heat because excessive heat disrupts the intermolecular bonds which stabilise the secondary and tertiary structure of an enzyme molecule(the enzyme molecule has a tertiary structure). The enzyme molecule unfolds and the precise shape of the active site is lost. This loss of structure and function is irreversible.

- Q:Junior high school chemistry - chemical reaction before and after the quality and chemical properties of the material must be the catalyst?

- It is not always possible that the equivalent reaction, i.e. one or more of the reactants, is the same as the relative atomic mass of one or more of the products and the coefficients in the chemical equation are the same

- Q:Word editor when playing chemical equation = with the above conditions or how to adjust the size of the catalyst, how to make it centered,

- Open the word - insert - object - WPS3.0 formula - and then select the "label arrow template", you can add a catalyst.

- Q:Can a catalyst decrease the rate of a chemical reaction? Please give an example if yes.

- A catalyst is something that quickens the fee of reaction without getting used up itself. They many times try this by skill of lowering the activation skill, which additionally brings the optimal temperature down. So, to place it only, it relatively is B.

- Q:What about the chemical reaction of the catalyst if there is no catalyst?

- Slow response or no reaction

- Q:What are the chemical reaction conditions in organic chemistry are catalyst and heating, please elaborate

- This really does not have omnipotent law, their own more than one point, you can classify to remember, when I was in high school is in accordance with the notes, such as poly, polycondensation and the like. In general, the double triple bond addition, plus halogen is not the conditions, plus HCl, HBr and the like to heat; dehydration reaction generally concentrated H2SO4 heating, dehydration condensation is also; there are some special, such as ethylene added to ethanol Special temperature requirements, it seems that 120 degrees, there are other; other addition poly, polycondensation some need catalyst. The The In short, the conditions are many, in general, you do not go to the high school to do more questions after the feeling, encounter problems do not panic general experience can come out according to experience, this also depends on the usual accumulation, if the equation conditions Wrong to deduct points, it is not worthwhile. There are some questions when the examination will give you some information, whether you know do not know should see clearly, although some of the reaction but the subject to the conditions are not the same, when you do according to the title to write conditions, this will not wrong. In addition, thank you for your help, I do not seem to know you

- Q:To write a 1500 words of small papers, so please help you busy

- Change the course of the reaction

- Q:I was hoping to buy a land rover lr4 or lr2, but with the lr4 having gas mileage in the mid teens, i wanted to know if there is a way to improve it. I dont drive on the highway too much. I'd like to know if there is anything else to improve mileage too. I drive a lot of people around for functions, family, and others and I looked at other suvs but those two looked the best.

- A okorder /... Real world test is the sure proof.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dioctyl Phthalate (DOP) alternative DEDB for PVC Plasticizer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16.8

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords