DIN Standard Horizontal End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

End Suction Centrifugal Pump

1.Structure of End Suction Centrifugal Pump Description

End Suction Centrifugal Pump complies fully to the European Standard BS EN733 / DIN24255 of performance and dimensions. They are used for pumping clean water or liquids similar to water, achieving wide application on plants, mines, city water supplies, air-conditioning coolers, firefighting system and irrigation. Pumps of the same model have different performance levels basing on different diameter after impeller trimming. Overall the whole series, there are only four sizes of shaft and five of bearing housing. As long as their bearing housings are of the same size, different pumps can interchange chief parts such as shaft, shaft sleeve, shaft seal, impeller nut, etc.

End Suction Centrifugal Pump is also very easy to be installed and maintained. Back pull-out design, driven through flexible coupling, so that pump casing and motor can remain in position while other spare parts are removed.

2.Main Features of the End Suction Water Pump

• very easy to be installed and maintained

•Back pull-out design

•Driven through flexible coupling

•Customized design is available, OEM and ODM are welcomed.

•Horizontally and vertically installation as different pipeline system

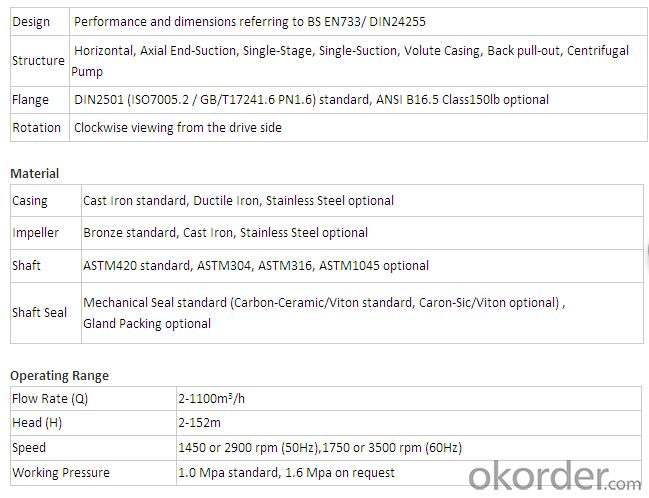

3.End Suction Water Pump Specification

4.Picture of End Suction Pump

5.FAQ

① What is your product range?

Centrifugal pump, slurry pump, gravel pump, clean water pump, sewage pump, chemical pump, single stage

pump, double suction pump, industry pump, oil pump, paper pulp pump, mud pump, self-priming pump, pipe

water pump, boiler water pump, etc.

② Are you a manufacturer?

Yes, we have been in manufacturing and marketing industry centrifugal pump over 20 years.

③ What information should I let you know if I want to get a quotation?

Pump capacity, pump head, medium, medium temperature, pump material, quantity, if possible, please also provide the pump model you are using now, price will be calculated as per the pump model, if not, we will recommend relevant product for reference.

- Q:Okay, i have a 1997 dodge stratus with a 2.4l motor, recently i was out early in the morning when i heard what sounded like a loud whining noise, i quickly pulled over and killed the motor. Turns out the teeth were stripped off the timing belt and the water pump busted. How much would this cost to get it fixed, and what is the possibility the engine may be damaged? Also would it be worth fixing it, or just selling it for parts? Oh yeah, the car has 176k miles

- yes its probably worth fixing ,you shouldn't have no engine damage to it because that one doesn't run an interference engine ,all that should have to be done is new pulleys and a water pump,and new timing belt kit put on it,all of this will cost around 3-400 bucks though for everything,but its probably worth repairing,you cant buy a good car for 400 bucks,and if it ran well before then it should be alright once you get it repaired,good luck with it i own on of those and their good cars.

- Q:In case our electric goes out we would like to be able to run the water pump (for the well) via solar panel. Can you give me instructions, pitfalls, recommendations, links etc to help me get started?The more solar info i can get the better!thanks 10 points on offer!Our sunlight is unobstructed

- Build okorder /

- Q:mercury 9.8hp.installed a new water pump impeller and still no water circulating through engine. no blockage anywhere. now what??? i`m stumped at this point.

- This engine has a hose that discharges a small stream of water when running. But most of the water is discharged through the center of the prop. It's not uncommon for this hose to plug from small bits of sand and mud. a small wire can unplug it. If the thermostat is stuck this might cause what your describing, but it's rare. Is it possible that the little round drive pin that goes between the impeller and the drive-shaft, broke or came out during assembly? Or the guide tube in the lower leg (intermediate housing) is not in place of blocked. Sometimes the sleeve that seals this gets crumpled under during installation and can block the flow. My recommendation is to disassemble and check each step until you've found the problem, or satisfied your self that everything is right.

- Q:I was was wondering how to calculate the head flow rate from a water pump. The water pump outputs 2 bar, which means that it will push water up to 20m in height. It also has a throughput of 2000 litres per hour.I want to pump water up to my loft, which is approx 15m above the pump.What will the flow rate be at this height? Is it a linear calculation of percentage of drop from maximum head height multiplied by the flow rate, (eg 5/20 * 2000 = 500 litres per hour?), or is it more complicated than that?

- If your pump has more capacity than you need, you can always restrict the discharge and create extra artificial head.

- Q:What are the conditions for the series and parallel connection of the pumps?

- Parallel pumps: the pump is required to lift the same. This effect is to increase traffic.Pumps in series: requirements are similar to the flow of water pumps. This allows you to increase the total head and recommend adding small pressure tanks during the series connection.

- Q:i was coming home from from work and my jeep thew the serpenteen belt and my water pump is the only pulley not moving good like the rest and is leaking coolent. and people with just dump **** to say dont comment on this

- With either engine your jeep cherokee would have a 2.5 or 4.0. Both have the same pump, and the 2.5 would be easier because you would have more space from the smaller engine. But there not hard to replace. A repair manual would be help full if you have never replaced a water pump before.

- Q:I have a 1998 ford taurus. It started to over heat so i turned on the heater full blast and it didn't get hot. so i put antifreeze in it and i turned it on and it seemed ok but it started to over heat again and the tank for the antifreeze looked like the cap was going to pop off. I was just down the road from my house so i thought if i drove slow i could make it home and it turned on ok but when i put it in drive it stalled. Does this mean its the water pump??????

- Its over heating because either your thermostat is messed up, bad water pump, head gasket, bad radiator.... but sense it was empty on fluid you could have a possible leak in the hoses or a head gasket or your water pump is leaking engine coolant. for head gasket check if theirs water in your oil ( take off the engine oil cap and see if theirs a white foam on it) if their is then your head gasket is screwed, to check if your water pump is working start the car after it has been sitting for a long time so its cold, touch the black hose thats ontop going into the radiator ( usually the biggest one you can see) and squeeze it while the car is running, if you feel water moving then your water pump is ok, you might have to wait a while for the car to get hot a little to check....cant think of anything else right now as im sleepy.

- Q:My 1999 ford taurus WATER pump and serpentine belt need to be replaced because I can't stir the stiring wheel .... Would you know approximately how much this could cost so I dont get ripped off ??? I know nothing about cars... and this mechanic is saying between 300$ to 400$ and that is wayyy too expensive . It was kinda obvious to him that I know nothing about carsTHANKS A LOT!!!

- This Site Might Help You. RE: How much would it cost approximately to replace a water pump and a serpentine belt for a ford taurus 99? My 1999 ford taurus WATER pump and serpentine belt need to be replaced because I can't stir the stiring wheel .... Would you know approximately how much this could cost so I dont get ripped off ?? I know nothing about cars... and this mechanic is saying between 300$ to 400$ and that is wayyy...

- Q:It's been slowly leaking for awhile now, but today it dumped brown water out like a bucket, when I shut it off facing up hill.

- you probably hit the nail on the head with the head gasket, but i believe there is also some kind of a heating device that helps to stop the water from getting into the engine. if the heating device breaks water can then condensate and get into the oil. i had to replace this device on my 93 grand am so i know it exists on some cars and trucks. ask around about this heating device. if it's the head gasket there is a STOP LEAK product that you can try from any auto store such as abc auto, pep boys etc. i've used it and sometimes it works sometime not. depends on how bad the leak is.

- Q:Colleagues, could you explain the principles of operation of the water vane vacuum pump? What range of pressure can one achieve with this type of vacuum pump? If somebody could post a reference to books, app notes, commercial datasheets of such pumps, that would be simply great.

- *Correctly said by Mr.Pete. I think you are asking about water ring vacuum pump. Basically it is a liquid ring vacuum pump. *A liquid ring pump is a rotating positive displacement pump. They are typically used as a vacuum pump but can also be used as a gas compressor. The function of a liquid ring pump is similar to a rotary vane pump the difference being that the vanes are an integral part of the rotor and churn a rotating ring of liquid to form the compression chamber seal. They are an inherently low friction design, with the rotor being the only moving part. Sliding friction is limited to the shaft seals. Liquid ring pumps are typically powered by an induction motor. *Single stage vacuum pumps typically produce vacuum to 35 torr (mm Hg) or 0.047 bar, and two-stage pumps can produce vacuum to 25 torr (mmHgA), assuming air is being pumped and the ring-liquid is water at 15°C (60F) or less. Dry air and 15°C sealant water temperature is the standard performance basis which most manufacturers use for their performance curves. *You have to take negative pressure if you are talking about pressure. Negative gauge pressure, a way of expressing pressure measurements below atmospheric pressure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

DIN Standard Horizontal End Suction Water Pump for Water Circulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords