Cylindrical Roller Bearing , Chinese Factory NJ 206 E

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Specifications:

Cylindrical roller and race for line contact bearing. Load capacity is big, mainly bear radial load .

1. Friction coefficient is small, suitable for high speed limit speed close to deep groove ball bearings

2.N and NU type axial movement, can adapt to shaft caused by thermal expansion or installation error and shell the change of relative position, can be used for free end bearing

3. On the shaft or hole of the processing and the demand is higher, bearing outer axis relative deflection after installation to be kept under strict control, so as not to cause contactstress concentration

4. Inner ring or outer ring separable, easy to install and remove

Specification | Model No.: NJ 206 E |

Brand Name: OEM | |

Size:30*62*16mm | |

Net weight: 0.210kg | |

Material: Chrome steel | |

Cage: Brass, Steel | |

Features: | 1) Precision: P6 P5 P4 P2 |

2) Noise level: Z1, Z2, Z3, Z4 | |

3) Vibration Level: V1, V2, V3, V4 | |

4) Clearance: C2, C3, C4 | |

5) Hardness: 58-63 HRC | |

6) Greese: As your requirement, such as SRL, PS2, Alvania R12 and so on. | |

Packing | 1.Industrial packing: box |

2.Commercial packing: box then into standard carton/wooden Box | |

3.According customer's requirement | |

Payment | T/T, L/C, Western Union |

Delivery time | About 3 to 5 working days |

Services | Warrantee: 1 year |

Samples: available | |

OEM: available | |

Free technical support and after-sales service |

Packaging & Delivery

Packaging Details: | plastics wrapping bearings - wrapping papers - polywoven bag - carton for outside package - wooden box /According to your order |

Delivery Detail: | 30-40days/according to your order |

Product Applications:

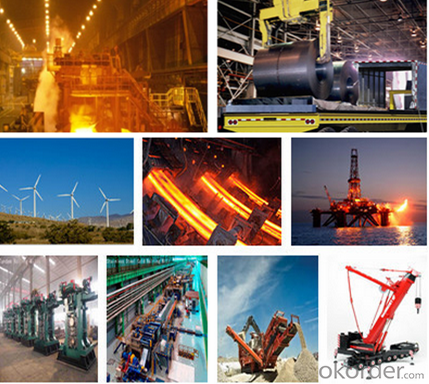

Cylindrical Roller Bearing Application Flied:Rolling Mills,Crusher,Mining

Metallurgy Petroleum,Chemical Industry,Engineering Machinery,Port,Oil,Gas,

Wind,Agriculture,Lathe,CNC,Steel Works,Electrical Machinery,Axle/Limber,

Tractor,Autocar,Crude Oil Engine and so on.

Our Advantages:

1. Excellent and high quality control

2. Prompt delivery

3. Competitive price

4. Small order accepted

5. Customers' drawing or samples accepted

6. OEM service

- Q:How much is the shaft shoulder height of the 81105 cylindrical roller bearings with inner diameter 25mm?

- The shoulder height (diameter) shall be smaller than the big diameter of the bearing (less than 42), mainly for easy unloading.

- Q:What is called a semi convex roller, a fully convex roller, a logarithmic curve roller?

- The logarithmic curve roller is also a convex roller, which belongs to a full convex roller;The shape roller refers to a roller which has a slight modification to the diameter of the outer end of the roller to prevent the stress concentration at the end of the contact between the roller and the raceway.The corresponding types of bearings are cylindrical roller bearings and tapered roller bearings. Modified roller and convex roller have been widely used in domestic roller bearings, which can improve the service life of the products.

- Q:What kind of material is used for cylindrical roller bearings?

- Products can be widely used in automobiles, motors, construction machinery, mining machinery, machine tools, metallurgy, textile, food, chemical and other enterprises. Our factory has Wuxi city Qikai bearing roller Co. Ltd.

- Q:Cylindrical roller and bearing outer ring processing is sheet metal forming?

- Sheet metal forming? You think too simple. Do you know that a key technical parameter of a machine part is called tolerance? The inner and outer rings and roller rolling bearings (ball, roller) have strict tolerance requirements, but also requires a very high hardness and abrasion resistance, the general is the use of special alloy steel, rolling (usually hot) heat treatment after forming, after precision machining (turning, grinding etc.) after finished product.

- Q:How to check the thrust cylindrical roller bearings?

- Bearing dimensions (or bearing samples) have "basic rated load (KN)", this column can be directly detected, in general, according to the use of appropriate multiplied by a (1.2~1.5) safety factor. In accordance with the requirements of the design manual, the equivalent load can be calculated (considering the speed, temperature, load and stability).

- Q:For example, NU, NJ, N, RNU, NUP, NF, NO, NN, RN, what do you mean, who can tell me about that hero?

- NU outer ring, double retaining ring, inner ring without edgeNJ outer ring, double retaining ring, inner ring, single edge

- Q:The Russian bearing suffix No. ZST is a cylindrical roller bearing

- The suffix code is not used to distinguish the bearings, but it helps to explain the structure of the bearings and the material.

- Q:Double row full cylindrical roller bearings, NNCF5008 installation, we need to pay attention to the direction of it?

- Double row cylindrical roller bearings have no directionality, so they do not need to pay attention to the direction! However, it should be noted that the inner ring and outer ring should be positioned separately to prevent axial movement!

- Q:Is the roller bearing and the bearing chamber movable in the tapered rotor motor?

- E in cylindrical roller bearing is the meaning of improving internal cage design, similar to the SKF cylindrical roller bearing EC form, this type of bearing than without E, is to strengthen the design, the roller is filled more larger to increase the load. From the load point of view, it is better to choose E.

- Q:Thrust cylindrical roller bearings, the main use?

- Thrust cylindrical roller bearings, the main use? Thrust cylindrical roller bearings are mainly used in oil rigs, iron, steel, machinery and so on. Our factory uses the bearings of Changzhou Enke Bearing Co., Ltd., they have many kinds of bearings and meet various demands.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cylindrical Roller Bearing , Chinese Factory NJ 206 E

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 set

- Supply Capability:

- 100000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords