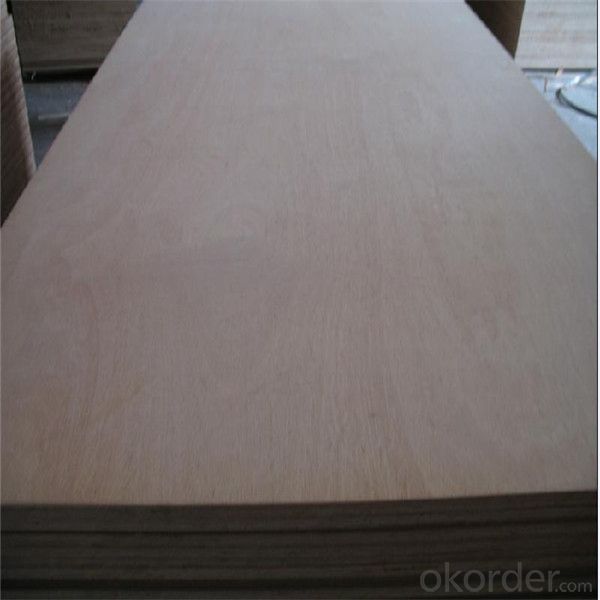

Concrete Commercial Plywood,Okoume Plywood,Bintangor Plywood with Hardwood/Poplar Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

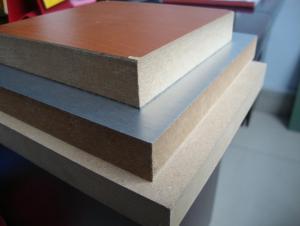

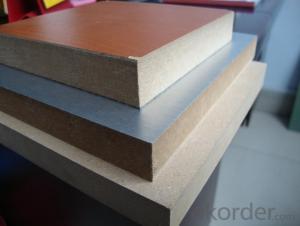

DESCRIPTION:

| Type: | Plywoods | Place of Origin: | Shandong, China (Mainland) | Brand Name: | CNBM |

| Model Number: | 1220x2440mm | Usage: | Indoor | Grade: | First-Class, bbcc grade |

| Main Material: | Poplar or Hardwood | Formaldehyde Emission Standards: | E0,E1,E2 | Plywood Type: | commercial plywood |

| name: | commercial plywood | Face/Back: | bintangor/okoume/pencil cedar and other red hardwood | Core: | poplar/hardwood/combi |

| Glue: | MR/E0/E1/E2 | size: | 1220x2440x1.6-18mm | purpose: | decorative and furniture |

SPECIFICATION:

Commodity | High quality | Bintangor/okoume plywood (furniture plywood) | ||

Spec. | Size | 1220*2440mm&915*2135mm or as your dedemand | ||

Thickness | 2.4mm-25mm | |||

Glue | MR/WBP/E1/E2 | |||

Face and back | Okoume,bintangor,hardwood,pine,keruing,birch, teak,sapeli,oak,ebony,or your deand | |||

Grade | BB/BB,BB/CC,CC/DD,packing grade | |||

Core | Poplar,hardwood,eucalyptus,birch etc | |||

Moisture | 4%-14% | |||

Thickness Tolerance | <6mm< span=""> | (+/-)0.2mm to 0.3mm | ||

6-30mm | (+/-)0.4mm to 0.5mm | |||

Packing | Inner packing | 0.2mm plastice bag | ||

OuterPacking | pallet all covered by strength plywood and resinforced by steel tapes | |||

Quantity | 20’GP | 8pallets | ||

40’GP | 16pallets | |||

40’HQ | 18pallets | |||

Usage | MR glue plywood used in interior for decoratin,room furniture | |||

WBP plywood used in exterior for construction | ||||

MOQ | 1*20GP | |||

Payment | T/T or L/C at sight | |||

Delivery Time |

Within 10-15 days after receiiving deposit or original L/C at sight | |||

Certificate | American CRAB,ISO9001 | |||

FEATURE:

1. We have 20 years of experience in export board.

2. We are professional in the manufacturing wood board.

3. We can offer you competitive price with lowest cost but good quality.

PICTURES:

- Q:What are the advantages of ecological boards and other boards?

- Ecological board itself is very toxic, relatively stable, no toxicity after curing. The production of furniture, ecological board on the air pollution is determined by the ecological board used in the MDF or particleboard substrate, if the substrate formaldehyde emission to meet environmental standards, ecological board will not exacerbate the material pollution, "ecological sheet without any Odor, odor is the quality of the sub-density plate, the use of adhesives or additives containing formaldehyde and other substances distributed to prevent the edge of the crack

- Q:What is teak finish?

- (Veneer), full name decorative veneer veneer plywood, it is the natural wood or technology wood slices cut into a certain thickness of the film, adhere to the plywood surface, and then made of hot for a decoration or Furniture made of surface material.

- Q:Solid wood veneer surface of the veneer how many kinds of materials

- As the real wood leather mostly used white oak and cherry wood and other precious species, combined with advanced technology and process production, the effect is even better than the average solid wood furniture, the price is cheaper than solid wood furniture, it is also easy to be accepted by working class.

- Q:Do you want to paint the panel, what panel?

- Not to do the panel can do, but the effect in general. Because the MDF surface overlay is very general.

- Q:What is a stone trim? Home stone panel okay?

- High-quality panel requirements beautiful and generous, pattern (string) plywood requirements texture clear, wood grain symmetry, no obvious color, no dead, no digging, no sand injury, indentation, no plate stains, smooth and smooth; Radial) Veneer requirements texture straight, no obvious color, no point of the child. Commonly used veneer, gluing strength 0.5Mpa, impregnated stripping each side 1/3, moisture content of 6-14%.

- Q:Wooden door surface panels (multi-layer board) is a solid wood door or solid wood composite door?

- According to the solid wood doors are not posted, solid wood doors of the process is generally refers to the section, or pure wood.

- Q:Do you have a solid wood paste or a solid wood paste?

- With the MDF to be better, not the heart from the skin

- Q:What are the patterns of kitchen design?

- 4. Metal foil veneer This is newly developed in recent years, mainly used in the need to have a metal surface decoration of the panel, can reduce the amount of metal, such as aluminum foil panel for the elevator wall, copper panel for the door decoration. Its advantage is good decorative effect.

- Q:What are the identification methods for the panel?

- Generally carried out in the vertical sawing or grinding method is used, are visible traces of the content.

- Q:What are the quality requirements for decorative panels?

- Decorative panels - the construction quality requirements: First, first of all depends on the floor of the panel is flat, solid Second, depends on the panel texture direction or pattern is not one to third, look at the face of the panel is empty , Look around the panel is not sticky

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Concrete Commercial Plywood,Okoume Plywood,Bintangor Plywood with Hardwood/Poplar Core

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords