Com Ceramic Fiber Wool Blanket for Hot Blast Furnace Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Com Ceramic Fiber Wool Blanket for Hot Blast Furnace Made In China

About Ceramic Fibre Blanket for Hot Blast Furnace

Ceramic Fibre blanket is ideal thermal insulation material, fire-proof material and sound-absorbing material. Ceramic fiber blanket has even texture and smooth surface.

Packaging & Delivery

Packaging Details:1.carton with inner PVC bags carton size:460*460*620mm 1*20FCL load 225cartons , 1*40FCL load450 cartons 1*40HC load 525 cartons 2.woven bags with inner PVC bags: 1*20 FCL load 225bags, 1*40 HC load 620bags

Delivery Detail:10-15 days after deposit

Characteristics of Ceramic Fibre Blanket for Hot Blast Furnace

1. low thermal conductivity ,low heat capacity

2. excellent heat stability and thermal shock resistance

3.good performance of thermal insulation, fire-proof and sound-absorbing

4. ultimate tensile strength

5. no delamination

Applications of Ceramic Fibre Blanket for Hot Blast Furnace

1.Industrial furnace, heating devices, high temperature pipe

2.High building fireproof ,sound-absorbing and thermal insulation material

3.Thermal insulation material for the electricity boilers, gas turbine and nuclear power.

4.Wall linings of the chemical high-temperature reaction equipment and heating equipment.

5.Thermal insulation for the furnace door and roof.

Images

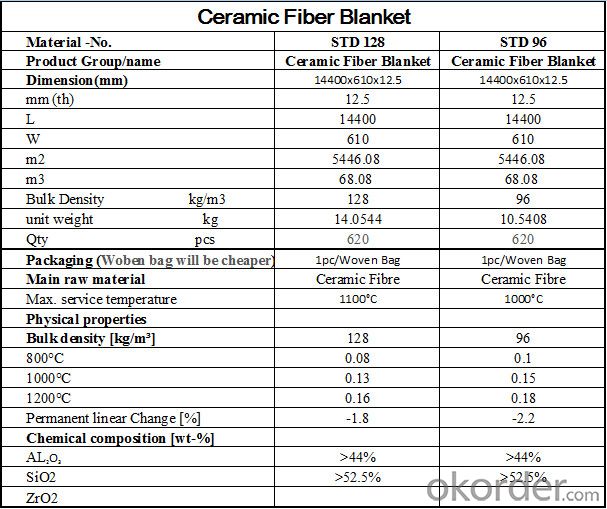

Technical data of Ceramic Fibre Blanket

FAQ

Q1:How to slove the quality problems?

A:If the products are not confirmed to customer samples or have quality problems,our compay will be responsible to make compensation for it.

Q2:Can you offers samples?

A:Of coures,samples are free but freight paid by the buyers.

Q3:What is the service life of your products?

A:The service life of different ceramic fiber is unlike.It also depends on your using condition and method.

- Q:I live in Southern California and own a 20 year old thoroughbred geldingAs a thoroughbred, he is always on the thin sideHe is fed plenty throughout the day, 2 8-10lb alfalfa flakes, 5lbs safe choice, 6lbs beet pulp, 2lbs rice bran and 10lbs alfalfa pelletsHe looks great right now, but I worry if I don't blanket him he could go thinHe boards in a facility across town, so blanketing him is not the most convenient, as I can not be there in the morning to remove his blanketIt is 50 degrees right now (8:30pm) and I am cold, but I know not to judge my temp to my horseI checked on him earlier and he seemed just fine.Those I have spoken to say I don't need to blanket him unless it is rainy and cold (rare occurrence here)So, at what temperature should I throw a blanket on him (if ever)? Do horses in Southern Cal (specifically Carlsbad) need blanketing?Thank you for your help.Concerned owner.

- Honestly, It sounds like gasYour appendix is in the right middle/lower side of your abdomenSo that would not be itThere really aren't any organs on the left upper side except intestines and they can cause painful gasTry to lay off the soda and drink some waterAlso avoid foods that cause gas like beans and some greens, etc.

- Q:Hi there, I am hoping someone who knows a little bit about yarn can help me outI have a project that I have been working on forever with dry clean only fancy schmancy yarnLast night I spilled red kool-aid on in while I was asleep(I am a restless sleeper, and always thirsty) I totally forgot to move the yarn to a safe place before I went to bedWhere I am not done knitting some of the yarn (read: most of it) is there any way to have it dry cleaned BEFORE I knit it, to get the kool-aid out? If not, I am open to all suggestions about how to get the stain out!!! It was kind of expensive yarn, and I really really want to make sure it doesnt stain! Thanks in advance!

- If the yarn is wool, I'm afraid you are out of luckOne popular way to dye wool yarn (and about anything else) is Kool-aidAsk a dry cleaner first before doing any more work on your projectI think it would be safer to clean it after you knit itIf it is wool you don't want to take the chance of felting the yarnGood luck.

- Q:one day I'm fine and doing greatSuddenly, the next day I'm having trouble with constipationI know it's not a pleasant thing to ask but I was wondering how it suddenly happenI haven't changed my diet or anything or eaten or drank anything unusualI was fine then suddenly I'm not and I can't remember what I have changed to make this happen? I also noticed that I had a little bit of gas and I think that's what caused it but not sure what happened if I haven't changed anything.

- Foamglass is OK as long as you are above the freezing pointI worked on one brine system which had old foamglass, and even though they claim it is impermeable, this stuff had been completely permeated, and had the insulating properties of frozen mud [which I looked up in Perry's and compared to the heat load at 'idle' and found a good match] However, I have seen plenty of other types of insulation used, from Cal-Sil to fiberglass to urethaneSelection criteria will involve materials and installation cost, the cost of an extra BTU getting into the chilled water, and durability questions.

- Q:I know that vampires don't exist (although I must say I'm interested in vampiric lore and mythology), but I'm just curious if one can survive just by drinking bloodIt seems like blood has all elements, which our metabolism require but I think I'm wrong and there have to be also some digestive problems (which?).

- No,one cannot survive just by drinking human blood and for many reasons including: 1Human blood is a specialized fluid primarily used for transporting oxygen, nutrients, etcIt is not an accurate representation of the chemical makeup of the human body.We require all sorts of vitamins, minerals and chemical fuel that are in short supply in bloodYou'd end up with severe potassium deficiency (you'd need to drink 10 gallons of blood per day to get your recommended daily allowance of potassium) as well as deficiency of all the fat-soluble vitamins2Even a small amount of blood in the stomach will make a person throw upThis is why bloody noses or certain injuries can cause people to vomit-they've inadvertently swallowed blood3Iron poisoning can even be a problem4.You'd become wildly constipated (complete lack of fiber and clotting nature of the blood), which can also kill you5.May also lead to rapid dehydration and electrolyte imbalance leading to cardiac arrhythmia and death.

- Q:The Australian Government will soon be offering subsidies to home owners who do not currently have ceiling insulation.What are my best choices? There seem to be quite few on offer.Thanks.

- Cellulose is a very environmentally safe material to use, and inexpensive, too.

- Q:My dad has 5 sheep and 2 alpacasThey get shorn every year, because they have toAnd so we have a shed full of wool (mostly because we are too lazy to get it spun and stuff)But I was thinking about it, and would you (a vegan) not wear/use this wool? What would you propose happens to it in a perfect all-vegan world, it be thrown away, or what?I'm not trying to be offensive or anything like that, I'm just wonderingWool is the one thing I just don't get about veganism.

- hmm depends on what your doing like if your baking a cookie then sure! but like if your getting highlights or something then that's a problem.

- Q:I want to know whether there are any hobby stores on Guam, like Hobby Lobby, Jo-Anns etc.Especially interested in scrapbooking and wood craft supplies.Thanks!

- in case you reside everywhere close to farms with any form of animal, touch themthey might enable you have it for looseotherwise, OKorder, etsy, and craigslist, or your community yarn shoppeople who elect to spin comprehend people who've uncooked wool.

- Q:just couple of simple questions for any experts out there:the insulation will be used in different areas so im looking for the best of both areasThanksWhat is the best heat insulation?What is the best sound insulation?

- That's gonna be tight Best thing would be to go to a grocery store with a bulk section and loading up on oatmeal, beans, lentils, rice, and frozen vegetables (don't overlook spinach and other leafy greens - far superior to lettuce and cheaper)You can get a few loaves of bread and freeze the ones you are not usingIt will make the bread kinda stale, but you can toast it and it's fine againI would consider 'beans rice' type dishes like Cajun red beans and rice, Indian dal/channa, etcYou can more or less add any of the frozen vegetables to such dishes (or to ramen soups) or steam them as sides (adding lemon juice and spices/herbs for flavor)Since it's winter, chili and crock pot type stews are a wise idea tooStew meats can be reasonably pricedAlso, check out actual meat markets rather than grocery butcher counters/meat sections for bargainsI was amazed at how cheap a leg of lamb at the meat market was compared to the grocery sale priceSausages tend to be cheap, tooAlso, I suggest stealing toilet paper and hand napkins from work or public restroomsThat stuff is not cheapKinda ghetto, but you do what you gotta do until you can do what you want to doGood luck.

- Q:For a horse that isn't clipped and is mostly in a barn what temperature do you start to blanket??

- If the horse is inside and has it's natural winter coat, I put a sheet on at 45, a blanket at 40, and both if it gets near freezingI do more than most, but they're show horses and I don't want them growing a really thick coatFor a clipped horse, even if it has grown back some of it's coat, I start with the sheet at 55, blanket at 50, and both at 45When it gets really cold, I'll add a slinky(Florida - our horses do not know how to deal with cold)

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Com Ceramic Fiber Wool Blanket for Hot Blast Furnace Made In China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords