CMAX Rotary drilling rig for Sale on OKORDER High Tech

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

A solution to problems with cast-in-place pile construction of 400~600m housing construction

| Easier transportation, lower cost and higher efficiency |

| High stability and anti-tipping capacity Arranging the main and auxiliary winches at the lower end lowers the center of gravity of the drilling machine during operation and transportation, and improves the stability of the complete machine. The steel wire rope is used to hoist the drilling stem and drilling rigs directly through the goose head pulley. This can prolong the service life of the steel wire rope. |

| Compact, flexible and highly maneuverable Compact machine body ensures a satisfactory passage capacity and can accommodate pile pore construction in narrow space. It is a truly buster at the construction site. |

Stable and reliable

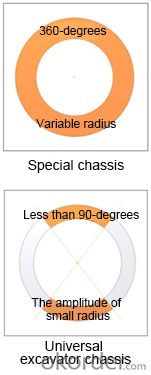

| Special chassis The self-made special hydraulic flexible chassis structure suitable for the actual load is adopted. Meanwhile, the main and auxiliary winches are installed on the rotating platform, which remarkably reduces the tipping load and guarantees the stability of the complete machine fundamentally. The position of the gravity center of the complete machine is optimized, with the stability angle increased from 10° to 15°. This guarantees operation stability on all dimensions of 360°. |

| Square-shaft casing structure The box type square shaft casing structure is used for the mast deflection seat. The force of mast is directly transferred onto the trolley traveling mechanism, thus eliminating the stress of the rotary frilling force on weak links of the deflection seat and improving the structural stability and reliability. |

| Mast structure The high-strength anti-deform design is used for the drilling stem. The rectangular mast section is even wider on the guide rail direction. This can effectively reduce the structural stress of the mast and make it more suitable for the in-rock construction conditions with high-strength variable and constant load. |

| Winch The main and auxiliary winches are installed on the platform, which greatly reduces the tipping torque of the operation device and the revolving inertia of the upper part of the platform and improves the stability of the complete machine. |

| Auxiliary landing leg The standing leg hidden below the lower mast can not only act as the auxiliary support for drilling construction, but can also help you with other unimaginable matters. |

High-grade configuration ensures high efficiency

The efficient and reliable engine is equipped with efficiency hydraulic transmission system, and this guarantees the strong power of the machine. The advance intelligent electronic control system can give full play to the efficiency of the machine. Meanwhile, the reasonable local structural design noticeably reduces the wearable and consumable.

| Complete machine system The engine of world-well-known brand is equipped with high-efficiency hydraulic transmission system. The advanced intelligent electronic control system can give full play to the efficiency of the machine. The complete machine system boasts advantages such as high reliability, fuel economy and high reserve power. The engine emission meets the European EPAC3 standard, which means the engine is environmental friendly. In addition, it can operate regularly even in alpine and high-altitude areas. |

| Power head The compact machine has a large-torque power head and boasts high speed. This ensures high construction efficiency. |

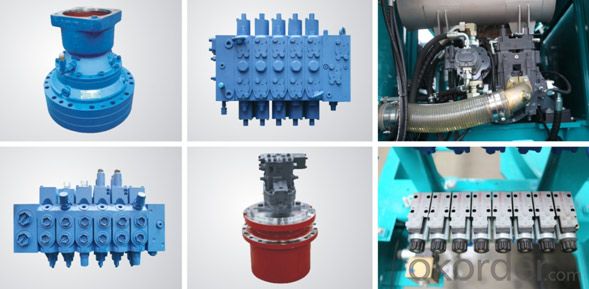

Hydraulic elements

The hydraulic system has been developed in joint efforts with a world first-class element manufacture to improve the hydraulic energy conversion rate of the element and reduce the transmission loss of pipelines of the system.

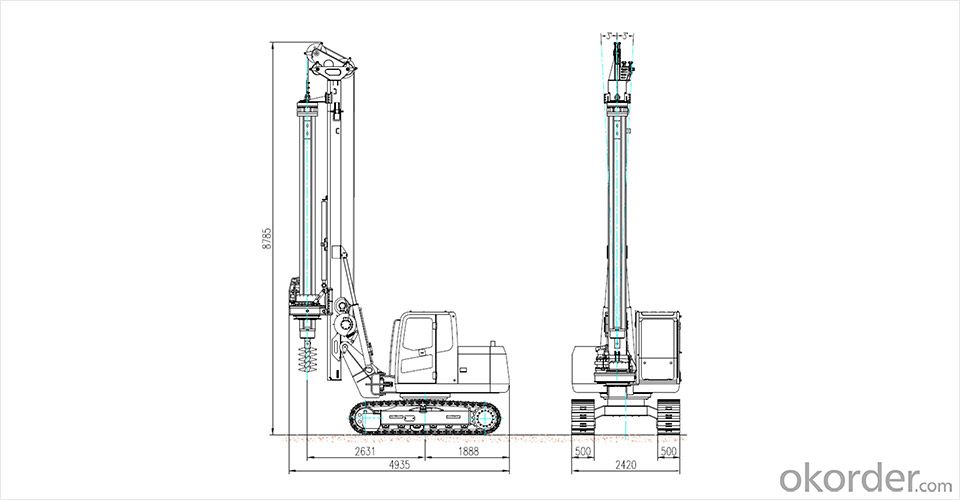

| Model | Unit | SWDM04 | ||

|---|---|---|---|---|

| Machine Height | m | 8.79 | ||

| Machine Weight | t | 16 | ||

| Max. Drilling Diameter | Drill Bucket Method | mm | 900 | |

| Max. Drilling Depth | m | 23 | ||

| Engine | Brand | Perkins | ||

| Model | 1104-44T | |||

| Rated power | kW/rpm | 74.5/2200 | ||

| Hydraulic System | Max.working pressure | Main pump | MPa | 34.3 |

| Auxiliary pump | MPa | / | ||

| Max.oil flow rate | Main pump | L/min | 2×110 | |

| Auxiliary pump | L/min | / | ||

| Rotary Head | Max. torque | kN.m | 40.8 | |

| Rev | rpm | 6~54 | ||

| in-off speed | rpm | / | ||

| Crowd System | Max. crowd push | kN | 60 | |

| Max. crowd pull | kN | 70 | ||

| Max. stroke | mm | 1500 | ||

| Main Winch | Max. crowd pull | kN | 60 | |

| Max. line speed | m/min | 66 | ||

| Auxiliary Winch | Max. crowd pull | kN | 15 | |

| Max. line speed | m/min | 50 | ||

| Mast Inclination | Left and Right tilt | ° | ±3 | |

| Forward tilt | ° | 5 | ||

| Undercarriage | Max. travel speed | km/h | 3 | |

| Max. grade ability | ° | 20 | ||

| Overall width of crawle | mm | 500 | ||

| Extendable crawler width | mm | 2420 | ||

| Width of track shoes | mm | 3415 | ||

| Grounding pressure | kPa | 59.6 | ||

Advantages

1 sincere

CNBM International is a state company, now is one of the largest state-owned group cooperation in China! All the outdoor heaters produced by CNBM are compliant with the national level quality.

2 professional

Our engineers will at your services 24hours to answer your questions. Our goal is to provide the best professional services.

3 quality

CNBM International’s outdoor heater have strict quality control, only the best quality products can pass the test.

4speed

We have professional sales team to guarantee your reply within 12hours to save your precious time.

5 After sales

If the tower crane has any problems, we will solve your problems in first time.

Others

1.Reply your inquiry in 24 working hours.

2.Experienced staffs answer all your questions in professional and fluent English.

3.Customized design is available. OEM is welcome.

4.Exclusive and unique solution can be provided to our customer by well-trained and professional engineers and staffs.

5.Special discount and protection of sales area provided to your distributor.

6.Do the best reliable heavy-duty single drum vibratory road roller in China.

7.Warranty period is 1-year or 1500 working hours against Bill of Lading.

Company Information

China National Building Materials Group Corporation is the full name of CNBM, which is one of the largest state-owned group in China. In 2013, the total asset of CNBM exceeds US$60 billion dollars with a total staff of 180,000. CNBM is listed in the World Top 500 Enterprises!

CNBM International works as the international platform for CNBM Group. In 2013, our total sales income was more than US$16.8 billion dollars.Every year we import large quantity of iron ore, coking coal and thermal coal etc from India, Brazil, Australia and Russia and other countries.ld'>Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

Our major responsibility is international marketing of different construction machinery & formwork, including lifting machinery, concrete machinery, earthmoving machinery, brick/block machinery; steel frame formwork, H20 timber beam formwork, aluminum formwork etc.

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

e. To provide customers with professional and technical services, to meet the demands of customers for construction efficiency and cost control, to achieve value for customers, which is the constant pursuit of Toppile, Toppile implant this concept in the whole process of sales and services.

Before sales

Research market with customers; provide technical advice, customized design and production.

f. On sales

Always communicate and adjust of design with customer to ensure the product satisfy all requirements.

After sales

Provide installation, adjustment, maintenance service, create customers files, following up machine working situation, provide customer a whole set of “Butler” and “Gapless”services.

g. Value added services

Redesign and upgrade the hydraulic system of piling machine, upgrade structure components.

Provide high quality and lower price components.

Toppile is the agent of many components factories, including cylinders, pumps, seals, hydraulic elements.

- Q:Which is better for the building foundation treated by a pile driver and a rammer?

- The piling machine is only the two way to deal with the foundation. There is no good or bad building. The building will not fall off without an earthquake.

- Q:Rural housing foundation, piling machine generally can play how deep?

- In a spiral track Matlock advantage:1 、 simple operation, one hole forming,2, fast, 3-5 minutes can become holes 5 meters3, the maximum diameter of the hole 800mm, the maximum hole depth of 10m, suitable for housing construction, highway, high-speed rail slope protection and other pile foundation construction4, special, mobile convenient, 360 degrees of free rotation5, firewood and electricity dual-use, reduce cost expensesA Hui Omron caterpillar rotary drilling rig advantage:1, the fastest 20 minutes, you can dig 5-8 meters of earth drilling2, drilling can break strong weathering rock layer3, the well-known brand of the engine, "Yuchai, Weichai, fuel consumption of 40-50 yuan per hour.4 、 selection of multi-functional parts, such as: Clay bit, sand fishing drill, bottom drill bit, easy to change, practical.

- Q:Do you make money on building pile drivers? How long will it take to recover the cost?

- To be honest, no money, no problem, it's hard to have a client.My father worked as an electrician at the construction site for three years. I just asked him.Of course, you have connections, and you won't do it.The most crucial thing is the network, there is a market, that thing good, tens of millions, smashing hands, crying dead.Sure, you have connections, when I don't say..

- Q:now to pull out, how can pull out? FiveThe machine can not be used, how to take out in a simple way! Now, how many tons of jacks do I need if I use a jack?

- Choose the proper crane and vibratory pile driver. Find out about the manufacturer.If Jack would estimate the pile weight of 14 tons, steel pipe in the soil weight of 50 tons, the friction pile is difficult to calculate, and the soil, curing time and pile, an estimated 600 tons to 2000 tons, to do a ring plate tooling, sheathed on the steel pipe, the gap should be small, on the tooling welding on the 1 meter long handle jack. Of course, you know, the hydraulic pad, the larger area, or the steel beam.

- Q:What are the characteristics of hydraulic static piling compared with traditional pile driver?

- No nuisance, you can work in the downtown area

- Q:I have a pile machine construction record card, but Supervision said or not, please master pointing.

- If there is any nonconformity, the rectification shall be completed and checked by the supervision.

- Q:I can drive an excavator and a hammer, but I want to learn how to drive a pile driver. How long will it take to learn?

- Very quickly, understand the working principle, work methods, basically on the line

- Q:Is the piling machine dangerous?

- The work environment is rather bitter, and in the hot days you have to drive a pile machine there, one by one! The difficulty is not too great!

- Q:What machinery is used for piling?

- In fact, in some places with artificial, you can go to buy a wylong machinery piling machine equipment is good, driving fast and convenient and money

- Q:What are the preparations for the piling site?

- 1, the pile position determination: according to the project provided by the construction unit and the pile axis location map of pile location, pile location must be accurate, and in the pile position by a soldering iron drilling, hole depth is 15~20cm, filled with lime, prevent in the process of driving the wrong pile.2. Pile up(1) pile stacking shall be determined by pile driving route and pile driving sequence(2) the site shall be level and level with three passes and one leveling. Remove obstacles in the ground, underground and air in the range of the moving of the pile driver. The wooden posts and the pile rings shall be of the same position, except for the contact between the pile and the pile, and nothing else shall be in contact with the pile so as to prevent cracks in the pile.(3) the strength of reinforced concrete precast piles must be up to 100% before they can be transported and piled3, the selection of pile machineAccording to the design of single pile bearing capacity and pile length, this project intends to use hammer weight 2.5t track type diesel pile driver.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Rotary drilling rig for Sale on OKORDER High Tech

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords