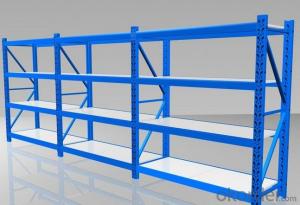

Cantilever Type Pallet Racking Shelving Systems

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

It's called cantilever racking system. The cantilever rack is used for long material, round goods, plates and pipes.

Cantilever rack is particularly used for specific products and easy for storage operation and convenient for warehouse.

The cantilever rack could be used for machinery manufacture industry and building material market.

Feature:

· For Small space and non-high warehouse.

· It's easy for management.

· With good vision.

Images:

Specification:

Length | less than 3000mm |

Width | less than 1500mm |

Height | less than 6000mm |

Loading capacity | 500-1000KG |

FAQ:

What is cantilever pallet racking system?

Cantilever pallet racking system is used for long goods and have good vision for small warehouse of limited height. It well make usage of the warehouse space.

How is quality guaranteed?

The production use professional roll forming technology and material of steel for production have strict test. The finished product into market are all guaranteed for users

How about the project installation?

Drawing for installation is provided for users. We also could send engineers to users's spot to carry out installation for project.

- Q:What are logistics facilities and equipment?

- Logistics facilities and equipment are the material and technical basis for organizing and conducting logistics activities.

- Q:How to do the warehouse logistics supervisor?

- Understand the type of storage, the amount of storage, the amount of work done, etc.. After understanding the warehouse function, we should clearly will be used for storage of goods warehouse properties, ordinary goods or special goods, in the control of temperature and humidity on whether there are specific requirements, if they need special anti-static turnover box and other special storage containers. If you do not understand, can go to such a comprehensive logistics Guanyu products supporting enterprises.

- Q:How to classify logistics facilities and equipment is more reasonable and scientific

- Logistics infrastructure mainly includes warehousing, carrying facilities, and computing and information communication equipment.Since human society has surplus production, there is storage, and warehouses are facilities for storing materials. In accordance with different angles, features and signs, the warehouse has its own warehouses, warehouses, public warehouses, bonded warehouses and bonded goods. Warehousing facilities play an important role in the whole logistics process:(1) the function of material storage. Any warehouse has a certain space to accommodate materials. The modern warehouse is not only a place for placing goods, but also a variety of facilities, with moderate storage and maintenance functions.(2) regulating the supply and demand of materials. There is a wide range of linkages between supply and demand as well as considerable complexity. When the supply and demand are unbalanced, the storage of the warehouse can act as a "reservoir" type.(3) regulating the function of material transportation. Transport capacity varies greatly because of the different means of transportation. The transportation contradiction caused by the difference of transportation capacity can be solved by the storage of materials, which is the function of material storage, regulation and transportation.(4) the function of material distribution. In modern logistics, warehouses in developed countries have been changed from original storage to distribution centers. That is to say to warehouse homework material sorting, matching, processing and circulation, in the new requirements, the warehouse has material distribution function.(5) the function of material saving. The role of material saving is indirectly manifested. Because people's production surplus is stored for a certain period of time without waste.

- Q:What are the responsibilities of the warehouse and logistics department?

- (1) responsible for drafting and revising the material storage management system of the company.(2) be responsible for the business instruction of other department's warehouse.(3) responsible for communication and coordination with all functional departments and related suppliers.

- Q:The differences and advantages between warehouse logistics and ocean shipping logistics

- To reduce reliance on artificial demand, especially the special storage environment to reduce the cost of human resources due to use of automation technology, automated warehouse can adapt to the needs of the dark, toxic, low temperature and other special occasions.

- Q:Question: what is the nature of logistics warehousing?

- However, the nature of the logistics project land with the functions of wholesale, retail and other market transactions should be recognized as commercial land

- Q:What are the logistics facilities and equipment in the supermarket?

- Boutique shelves, display rack, rack, titanium alloy, titanium alloy, Variety shelves, racks, steel rack, storage rack, display rack, CD rack, Variety shelves, storage shelves, sample rack, display cabinets, cabinet boutique, boutique shelves.

- Q:The role of warehouse management in Enterprises

- Warehouse management, that is, library management. Warehouse management refers to the warehouse and its inventory management, warehousing system is an indispensable subsystem of the enterprise logistics system. The overall objective of logistics system is to provide customers with satisfactory service at the lowest cost, while the warehouse system plays an important role in it. Storage activities can promote enterprises to improve customer service levels, and enhance the competitiveness of enterprises. Modern warehouse management has changed fundamentally from static management to dynamic management, and has put forward higher requirements for the basic work of warehouse management.

- Q:What is the warehouse keeper in the logistics industry?

- Warehouse Administrator (storekeeper), just as its name suggests, is to manage warehouse functions well through the management of warehouse items. Responsibilities include: acceptance of materials, equipment, entry and exit, accounting and payment in accordance with the regulations, so as to keep accounts consistent. Keep the stock status at all times to ensure the timely supply of materials and equipment, and give full play to the efficiency of turnover. Regular cleaning of the warehouse, keep the warehouse tidy and beautiful, and make materials and equipment arranged in different categories. Keep in good order and accurate quantity. Familiar with the corresponding materials, equipment varieties, specifications, models and performance, fill in clearly. Do a good job in warehouse safety management, check the warehouse fire, anti-theft facilities, plugging loopholes in a timely manner.

- Q:What are the common logistics equipment?

- According to the special functions of the equipment, it can be divided into transportation equipment, storage and storage equipment, loading and unloading equipment, circulation processing equipment, packaging equipment, information processing equipment, etc..

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Cantilever Type Pallet Racking Shelving Systems

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 10000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords