Butterfly Valve High Quality Ductile Iron Marine Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 999 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

Butterfly valve is mainly consisted of body, stem, disc, seat and driver(lever, gearbox, pneumatic and electric Actuator) and so on. On off and controlling flow of valve are made by turning stem and disc together.A butterfly valve is a valve which can be used for isolating or regulating flow.

Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow.

2.Main Features of the Manual Wafer Butterfly Valve

1)Flow curve tending to straight-line. Excellent regulation performance.

2)Small in size and light in weight and maintaince.

It can be mounted whereever needed.

3)Simple, compact structure, quick 90 degree on-off operation.

4)Disc has two-way bearing, perfect seal, without leakage under

the pressure test.

5)Various kinds of materials, applicable to different medium.

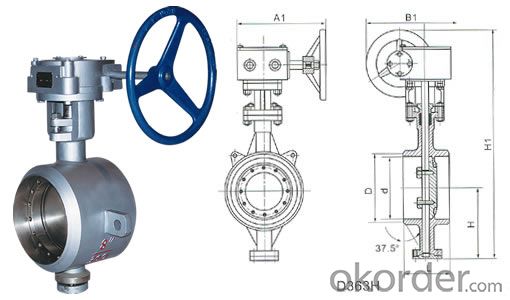

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q:DN80 flange butterfly valve, DN80 flange butterfly valve DN80, flange butterfly valve DN80 what is the difference?

- No, what's the difference?. It's not all the same.Flange connectionDN80 caliber butterfly valve. What's the difference?. Model and pressure. Materials are not ~!

- Q:Which is more expensive, gate valve or butterfly valve?

- Gate valve.Under normal circumstances, if you need to adjust the good point, to use the gate valve, and if better, you can choose the cut-off valve.But the price is also butterfly valve, gate valve, globe valve increasing.

- Q:Three eccentric hard sealing butterfly valve, why not fit in the end of the pipe?

- Louzhu asked extremely, since it is hard seal, it is bound to guarantee long-term work after zero leakage, or should be configured double eccentric soft sealing valve is more reasonable.

- Q:How do i use a valve spring compressor. It looks like a c-clamp, so don't tell me how to use a smaller one, but the bigger one.Thanks

- The forked end goes over the valve retainer, the flat end with the screw goes against the valve face. Simply close the handle to compress the spring. You may need to adjust the width of the jaws to fit the retainer and adjust the length of the screw to compress the spring the right amount. Sometimes it helps to gently tap the edge of the retainer with a hammer to loosen the keepers before compressing the spring.

- Q:Okay, so I've been thinking about trying to learn how to play my dad's baritone bugle, but I have no idea how to. If anyone had a good fingering chart for it, that would be great. The bugle has one valve and a trigger. I am a natural flute player and percussionist, so this is my first time playing a brass instrument. Needless to say I am very confused. Call me a noob, I don't care, as long as you get me a fingering chart for a 1 valve baritone bugle. Please help. :)

- Starting below the staff in treble clef - G - open (yeah, intonation heck) C - open D - valve (gap) F# - rotor G - open or valve (gap) Bb - Rotor valve B - Rotor OR valve (pick it) C - open C# - both D - valve D#(Eb) - rotor E - open F - valve F# - rotor G - open G#(Ab) - both (yech!) A - valve or rotor Bb - open or both B - valve or rotor C - open anything above C - dial it in. After seeing this, you'll know why going from G-D to G-F was such a radical improvement. After playing on this relic, you'll really appreciate what some of those corps had to do to sound good.

- Q:1988 volkswagon cabriolet, rabbit tried mystery oil let sit for a week having trouble with stuck valves even taken a wrenrch to manually unstick. help any suggestions 4 cyclinder car has been sitting up for about 4 years

- The only reason for a stuck valve is if it bent from a thrown timing belt. Sitting 4 years will not cause valves to stick usually, because there is always some oil leakage from the head, that prevents rust. How do you know the valve is stuck? Have you done a compression test, checked the valve clearance? When you say you take a wrench to manually unstick it, it would help to know what you mean, because there is no place to put a wrench that would help unstick a valve that was stuck. You need to tell us much more.

- Q:How do you explain A in butterfly valve D37A1?

- Represents a seal or lining material symbol.Said sealing ring or lining material with the Chinese phonetic alphabet: B Babbitts D nitrided steel, acid resistant stainless steel H, J L Aluminum Alloy, hard rubber, nylon NL, P leather, SA PTFE, SC PVC, SD bakelite, T copper, TC enamel, X rubber, Y hard alloy

- Q:Butterfly valve use

- On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. Butterfly valve is fully open to fully closed is usually less than 90 degrees, butterfly and butterfly stroke itself has no self-locking capability, in order to position the disc to install the valve stem on the worm gear.

- Q:Today saw the butterfly valve and butterfly valve, I do not know what is the difference between the two

- How it works: the disc is driven by the stem, and if it turns 90 degrees, it can be opened and closed once. By changing the deflection angle of the plate, the flow of the medium can be controlled. The main sealing element is a sealing ring, and the material is selected according to the use and the medium.

- Q:How do the butterfly valves d341 and d343 differ in appearance?

- Also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the flow of air, water, steam steam, all kinds of corrosive medium, mud, oil, metals and radioactive liquid media and other types of fluid. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation. According to type code, transmission mode, connection form, structure form, sealing surface material or lining material, nominal pressure, material of valve body, regulate butterfly valve type.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Butterfly Valve High Quality Ductile Iron Marine Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 999 pc

- Supply Capability:

- 9999 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords