Building Material Wall Panel ACP Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1.Structure of Building Material Wall Panel ACP Aluminum Sheet Description:

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above. 3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment

2.Main Features of Building Material Wall Panel ACP Aluminum Sheet :

Reasonable and stable chemical composition

Accurate tolerance

Nice mechanical property

Standards: EN, ASTM and EN

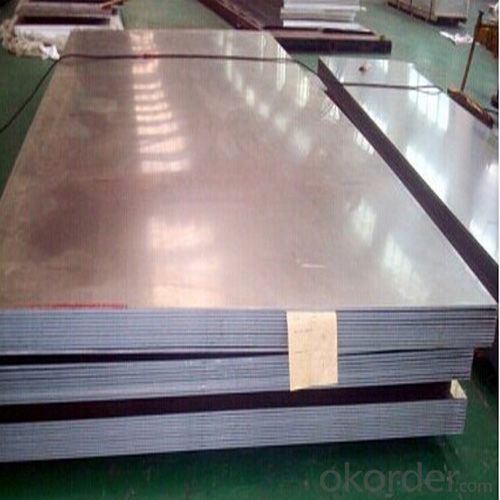

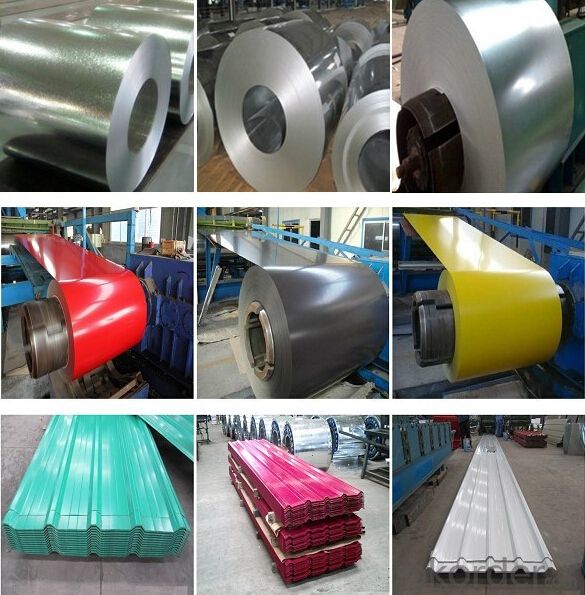

3.Building Material Wall Panel ACP Aluminum Sheet Images:

4. Building Material Wall Panel ACP Aluminum Sheet Specification:

1. | Item | Aluminum coil/ Aluminum strip,1070 aluminium coil | |

2. | Standard | ATSTM B209, JIS H4000-2006,GB/T3190-2008,GB/T3880-2006, etc. | |

3. | Material | 1000 Series:1050,1060,1080,1100,1435,etc. | |

2000 Series:2011,2014,2017,2024,2A12,2A16,2A06,etc. | |||

3000 Series:3002,3003,3004,3104,3204,3030,3A21,etc. | |||

5000 Series:5005,5025,5040,5052,5056,5083,5A05,etc. | |||

6000 Series:6003,6060,6082,6083,6063,6061,etc. | |||

7000 Series:7003,7005,7050,7075,etc. | |||

4. | Specifications | Thickness | 0.01mm~20mm |

Width | 10mm~2000mm | ||

Length | or as required | ||

6. | Surface | Bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc. | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q:why intact aluminum sheet stop quicker than pectinate one in the magnetic field?

- while swinging in the magnetic field, intact aluminum sheets will formulate inner eddy current,that is the annular induced current.eddy current will transform the mechanical energy into heat energy, which makes the aluminum sheet stop quickly.but pectinate aluminum sheet can't formulate intact eddy current, so intact aluminum sheet stop quicker than pectinate one.

- Q:Characteristics of anodized aluminium plate

- (1) good processing: anodized aluminum decorative strong, moderate hardness, easy bending forming, continuous high-speed, convenient and direct processing into products, no need for complicated surface treatment, greatly shorten the production cycle and reduce production cost.(2) good weather resistance: standard thickness of oxide film (3 m) anodized aluminum plate, indoor use for a long time, no discoloration, no corrosion, no oxidation, no rust. Anodized aluminum oxide film (10 m) can be used outdoors, and can be exposed to sunlight for a long time without discoloration.

- Q:answer them please! i need help. the main question is # 1!!! 2. how many atoms are in one particle of aluminum dichromate?3. how many phosphorus atoms are in one particle of calcium phosphate?4. how many total atoms are in one particle of calcium phosphate?PLEASE!! who ever answers all, ill give them best answer a 5 star ratinggg. please!!! THANK YOU!

- 1) Look at the formula for aluminum nitrate [Al(NO3)3]. The subscript of 3 outside of the parentheses means that you multiply each atom inside the parentheses by 3. Since there is only one nitrogen inside the parentheses, this means that you multiply that by 3. There are a total of 3 nitrogen atoms in each molecule of aluminum nitrate. 2) The formula for aluminum dichromate is Al2(Cr2O7)3. Again, multiply each atom in the parentheses by 3, add them, then add 2 to that number for the aluminum. That's your answer. 3) The formula for calcium phosphate is Ca3(PO4)2. Multiply P by 2. 4) Follow the same steps as in #2, above.

- Q:3003H24 alloy aluminum plate refers to what kind of aluminum plate?

- Attached: O status: fully annealed to obtain the lowest strength of the processing products. 8 state: hard working state (9)To sum up: 3003 refers to the aluminum manganese alloy, H24 represents the process of rolling, through incomplete annealing to achieve the specified strength, hardness of an aluminum substrate. In addition to the 5 first series of aluminum magnesium alloy used in aluminum plate, the other 4 prefix silicon as the main alloying elements in zinc series, as the elements of the 7 prefix series.

- Q:What are the common uses of aluminum sheets?

- Aluminum sheets possess excellent properties, rendering them highly versatile and extensively utilized across various industries. Their applications encompass: 1. Construction: In the construction industry, aluminum sheets find common usage for roofing, siding, and insulation purposes. Their lightweight nature, durability, and resistance to corrosion make them ideal for shielding against the elements. 2. Transportation: The automotive and aerospace industries heavily rely on aluminum sheets. These sheets contribute to the manufacturing of car bodies, truck trailers, and aircraft parts owing to their impressive strength-to-weight ratio. Consequently, the utilization of aluminum sheets aids in enhancing fuel efficiency and reducing overall vehicle weight. 3. Packaging: Aluminum sheets serve as a popular choice for packaging purposes, specifically within the food and beverage industry. Cans, foils, and containers are frequently crafted from aluminum sheets, as they effectively safeguard packaged products by acting as barriers against moisture, light, and oxygen. 4. Electrical and Electronics: The electrical and electronics industry benefits from the application of aluminum sheets due to their exceptional conductivity. Their utilization extends to the manufacturing of electrical enclosures, heat sinks, and wiring, as they efficiently dissipate heat and protect delicate electronic components. 5. Marine Industry: Aluminum sheets hold significant value within the marine industry due to their resistance to corrosion. They are employed in the construction of boat hulls, ship fittings, and other marine equipment. The ability of aluminum sheets to withstand harsh marine environments, alongside their lightweight properties, renders them an appealing choice. 6. Decorative Applications: Architectural applications often feature aluminum sheets for their aesthetic appeal. These sheets can be effortlessly shaped, formed, and colored to create diverse decorative elements like wall cladding, ceilings, and decorative panels. In conclusion, aluminum sheets serve as a fundamental material across numerous industries, including construction, transportation, packaging, electrical and electronics, marine, and decorative applications. Their versatility and significance are evident in their widespread utilization throughout various sectors.

- Q:Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Its lightweight nature, durability, and versatility make it a popular choice for various decorative applications such as signage, wall cladding, ceiling panels, furniture accents, and more. Additionally, aluminum sheets can be easily manipulated, painted, or coated to achieve different finishes, colors, and textures, allowing for endless possibilities in decorative design.

- Q:Are aluminum sheets corrosion-resistant?

- Yes, aluminum sheets are corrosion-resistant due to the formation of a protective oxide layer on their surface.

- Q:Are aluminum sheets suitable for beverage cans?

- Yes, aluminum sheets are suitable for beverage cans. Aluminum is a widely used material in the beverage industry due to its unique properties. It is lightweight, corrosion-resistant, and provides an excellent barrier against light, oxygen, and moisture, which helps to preserve the quality and freshness of the beverage. Additionally, aluminum is easily formable, allowing for the production of various can shapes and sizes. It is also recyclable, making it an environmentally friendly choice. Overall, aluminum sheets are an ideal material for beverage cans, meeting both functional and sustainability requirements.

- Q:Can aluminum sheets be used for heat dissipation?

- Yes, aluminum sheets can be used for heat dissipation due to their high thermal conductivity.

- Q:Can aluminum sheets be perforated?

- Indeed, it is possible to perforate aluminum sheets. Perforating entails either punching holes or generating a pattern of holes in a material. Aluminum, being a flexible and adaptable metal, can be easily perforated through a variety of techniques like punching, drilling, or laser cutting. The perforation of aluminum sheets can have numerous applications, including facilitating airflow, reducing weight, improving aesthetics, or constructing filtration systems. The dimensions, form, and layout of the perforations can be tailored to satisfy particular demands and design preferences. In summary, perforating aluminum sheets can effectively enhance their functionality and visual allure.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Material Wall Panel ACP Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords