Aluminium Profile Manufacturer Offer Different Type for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of Aluminium Profile Manufacturer Offer Different Type for Sale

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminium Profile Manufacturer Offer Different Type for Sale

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminium Profile Manufacturer Offer Different Type for Sale

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

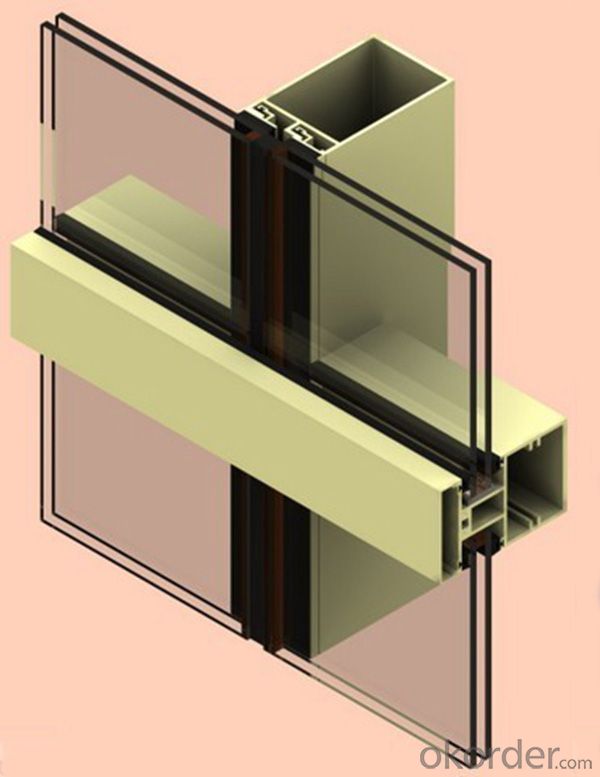

5. Image of Aluminium Profile Manufacturer Offer Different Type for Sale

6. Package and shipping of Aluminium Profile Manufacturer Offer Different Type for Sale

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q:How do aluminum profiles perform in terms of weather resistance?

- Aluminum profiles are known for their exceptional weather resistance. This is due to the inherent properties of aluminum, such as its corrosion resistance and ability to withstand harsh environmental conditions. Aluminum profiles are typically coated or anodized to further enhance their weather resistance, ensuring long-term durability and protection against various weather elements. Aluminum's corrosion resistance is particularly advantageous in outdoor applications. It forms a natural oxide layer when exposed to oxygen, which acts as a protective barrier against rust and deterioration. This makes aluminum profiles highly resistant to moisture, rain, and humidity, making them suitable for use in coastal areas or regions with high levels of precipitation. Furthermore, aluminum profiles are also resistant to UV radiation. The surface treatment, such as powder coating or anodizing, provides an additional layer of protection against the sun's harsh rays. This prevents the aluminum from fading, chipping, or cracking when exposed to prolonged sunlight, ensuring the profiles retain their original appearance and structural integrity over time. In terms of extreme weather conditions, aluminum profiles are designed to withstand high winds, extreme temperatures, and even severe storms. They have excellent mechanical properties, including high strength and stiffness, which enable them to withstand heavy loads and resist deformation. This makes aluminum profiles ideal for use in construction, architecture, and outdoor infrastructure projects where weather resistance is crucial. Overall, aluminum profiles perform exceptionally well in terms of weather resistance. Their natural corrosion resistance, combined with the various surface treatments available, ensures that they can withstand a wide range of weather conditions without losing their structural integrity or aesthetic appeal.

- Q:How do you prevent warping or distortion of aluminum profiles during fabrication?

- In order to prevent warping or distortion of aluminum profiles during fabrication, there are several key measures that can be implemented: 1. Storage in a controlled environment is crucial prior to fabrication. It is essential to store the aluminum profiles in an environment with stable temperature and humidity levels. This will help minimize any potential changes in the shape or dimensions of the metal. 2. Proper handling techniques must be employed to avoid bending or twisting the aluminum profiles. This includes using appropriate lifting equipment, avoiding excessive force, and ensuring even support during transportation. 3. During the fabrication process, it is important to utilize suitable machining techniques that minimize heat buildup. Excessive heat can cause the aluminum to expand and potentially warp. Utilizing cooling techniques such as lubricants or coolants can disperse heat and prevent distortion. 4. Controlled welding is crucial when working with aluminum profiles. Maintaining proper control over the welding process is essential. Employing appropriate welding techniques, such as preheating and post-weld heat treatment, can help minimize distortion. 5. Adequate fixturing methods should be employed during fabrication to ensure that the aluminum profiles are held in the correct position throughout the process. This prevents unintended bending or warping that could occur due to improper support or clamping. 6. Stress-relieving processes can be implemented after fabrication to minimize residual stresses within the aluminum profiles. This will prevent distortion or warping that may occur during subsequent handling or usage. 7. Regular inspection and measurement of the aluminum profiles during fabrication is necessary to identify any deviations from the desired specifications. This enables prompt corrective actions to be taken, reducing the risk of warping or distortion. By implementing these steps, manufacturers can significantly decrease the likelihood of warping or distortion in aluminum profiles during fabrication, ensuring the production of high-quality components or products.

- Q:What are the features of the poor aluminum profiles?

- Poor quality aluminum profile:1, chemical composition unqualified, seriously endanger the safety of construction projects.2 、 profile corrosion resistance function is low.3, the film thickness is thin. The national standard rules of construction of aluminum oxide film thickness not less than 10um (m). The thickness is not enough, aluminum looks easy to rust and corrosion. Some no name and address, production license, certificate of inspection in the aluminum oxide film, the thickness of only 2 to 4um, some even without film.

- Q:Can aluminum profiles be used for window frames?

- Yes, aluminum profiles can be used for window frames. Aluminum is a popular material choice for window frames due to its durability, strength, and resistance to corrosion. It is lightweight, easy to shape, and can withstand various weather conditions, making it a suitable option for window frames. Additionally, aluminum profiles can be customized to fit different window sizes and designs, making them a versatile choice.

- Q:3030 aluminum profiles, can be used in outdoor snow exposure environment?

- European standard 3030 series has a variety of specifications, such as Jing Teng aluminum European standard 3030R, referring to the European standard 3030 fan, 3030G refers to the 3030 GB profiles.

- Q:What are the different extrusion methods used for aluminum profiles?

- There are several different extrusion methods used for aluminum profiles, including direct extrusion, indirect extrusion, impact extrusion, and hydrostatic extrusion. Each method has its own advantages and is suited for specific applications. Direct extrusion involves pushing the aluminum billet through a die to create the desired shape, while indirect extrusion involves the billet being held stationary and the die moving towards it. Impact extrusion involves forcing the aluminum into a die cavity using a high-velocity impact, and hydrostatic extrusion uses high-pressure fluid to push the aluminum through the die.

- Q:What are the different surface sandblasting options for aluminum profiles?

- There are several surface sandblasting options available for aluminum profiles, each providing a unique finish and level of abrasiveness. 1. Fine sandblasting: This option involves using fine-grain sand or abrasive materials to gently remove surface imperfections and create a smooth finish on the aluminum profile. It is commonly used when a polished or satin appearance is desired. 2. Coarse sandblasting: Coarse sandblasting utilizes larger-grain sand or abrasive materials to provide a more rugged texture on the aluminum surface. This option is often chosen to create a matte or textured finish, which can help to hide scratches or other blemishes. 3. Glass bead blasting: In this method, small glass beads are propelled at high speed onto the aluminum profile's surface. This process is typically used to achieve a uniform and aesthetically pleasing matte finish. Glass bead blasting is also commonly employed when a certain level of reflectivity is desired. 4. Walnut shell blasting: This option involves using ground walnut shells as the blasting media. Walnut shell blasting is a more gentle technique compared to sandblasting, making it suitable for delicate aluminum profiles. It can effectively remove contaminants and provide a clean, smooth finish. 5. Shot peening: Shot peening is a specialized sandblasting process that involves bombarding the aluminum profile with small metal shots or pellets. This technique is primarily utilized to increase the strength and resistance to fatigue of the aluminum surface, rather than altering its appearance. It is important to consider the specific requirements and desired outcome when choosing a surface sandblasting option for aluminum profiles. Consulting with professionals in the field can help determine the most suitable method based on the desired finish, level of abrasiveness, and the aluminum profile's properties.

- Q:Can aluminum profiles be used for medical equipment or devices?

- Medical equipment or devices can indeed utilize aluminum profiles. The medical industry highly values aluminum due to its unique properties. It possesses a remarkable combination of being lightweight, yet sturdy and long-lasting, which renders it suitable for a wide range of medical applications. The utilization of aluminum profiles enables the production of medical equipment like hospital beds, wheelchairs, surgical tables, and diagnostic equipment. Moreover, aluminum's corrosion resistance makes it an ideal material for medical devices that frequently come into contact with bodily fluids or chemicals. Furthermore, aluminum can be easily sterilized, which is of utmost importance in healthcare settings where maintaining a hygienic environment is crucial. All in all, the utilization of aluminum profiles offers numerous benefits for medical equipment and devices, hence making it a popular choice in the medical industry.

- Q:Are aluminum profiles suitable for fencing and gates?

- Yes, aluminum profiles are suitable for fencing and gates. Aluminum is a durable and lightweight material that offers excellent resistance to rust and corrosion. It can withstand harsh weather conditions and requires minimal maintenance. Additionally, aluminum profiles can be easily customized and designed to suit various fencing and gate styles while providing a sleek and modern appearance.

- Q:Tips for identifying aluminum profiles

- For the mechanical framework of aluminum on the market quality is not good, consumers can use a simple method to distinguish aluminum, so you use the time better.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Profile Manufacturer Offer Different Type for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords