EN AW - 3105 Aluminium Treadplate for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

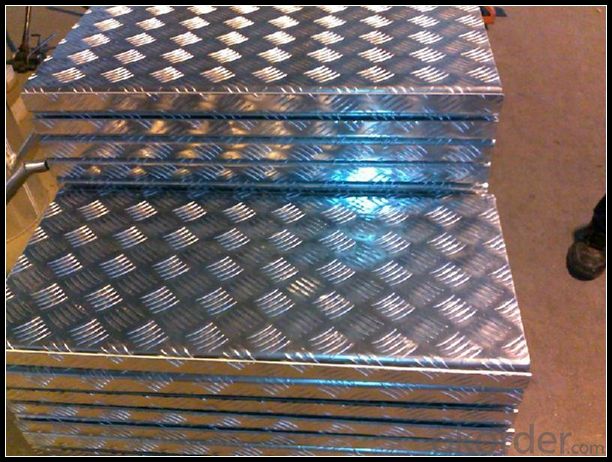

1. Structure of EN AW - 3105 Aluminium Treadplate for Building Description

EN AW - 3105 Aluminium Treadplate for Building is one semi-finished aluminium material. The alloy AA3105 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of EN AW - 3105 Aluminium Treadplate for Building

EN AW - 3105 Aluminium Treadplate for Building | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of EN AW - 3105 Aluminium Treadplate for Building

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of EN AW - 3105 Aluminium Treadplate for Building

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of EN AW - 3105 Aluminium Treadplate for Building

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

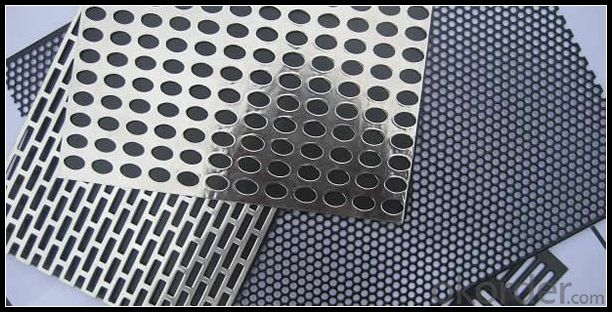

6. Image of EN AW - 3105 Aluminium Treadplate for Building

7. Package and shipping of EN AW - 3003 Aluminium Sheet for Circle

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What is the thermal conductivity of 101 aluminum sheets?

- The thermal conductivity of 101 aluminum sheets depends on various factors such as the thickness of the sheets, the purity of the aluminum, and the temperature at which the measurement is taken. Generally, aluminum has a high thermal conductivity, ranging from 205 to 250 watts per meter kelvin (W/mK). However, it is advisable to refer to specific technical data or consult with a manufacturer for accurate information on the thermal conductivity of 101 aluminum sheets.

- Q:What is the typical modulus of elasticity of aluminum sheets?

- The typical modulus of elasticity of aluminum sheets is around 70 GPa (Gigapascals).

- Q:I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Aluminum has to be extracted from the earth which is costly and takes a lot of energy. Then the aluminum needs to be smelted out of the rock that it is in, again this takes a lot of energy and creates toxins. Aluminum like all metals are finite, we conserve resources and the land where they will need to be extracted by recycling it.

- Q:What is the price range of aluminum sheets?

- The cost of aluminum sheets can fluctuate due to multiple elements, including the sheet's dimensions, thickness, and quality, as well as the supplier and market circumstances. Typically, the price of aluminum sheets can vary between approximately $0.50 and $5 per square foot. Thinner sheets or lower-quality aluminum tend to occupy the lower end of this price spectrum, while thicker sheets or higher-quality aluminum tend to fall on the higher end. It is advisable to compare prices among various suppliers to secure the most advantageous offer.

- Q:What are the different types of patterns available for textured aluminum sheets?

- There are several different types of patterns available for textured aluminum sheets, each offering a unique visual appeal and functionality. Some of the most common patterns include: 1. Diamond pattern: Also known as tread plate or checker plate, the diamond pattern features small raised diamonds on the surface of the sheet. This pattern offers excellent slip resistance, making it ideal for applications where traction is important, such as ramps, stairs, or industrial flooring. 2. Stucco pattern: The stucco pattern resembles a textured wall or ceiling finish, with raised ridges that create a rough and bumpy surface. This pattern is often used for decorative purposes, adding depth and visual interest to architectural elements like walls, ceilings, or furniture. 3. Hammered pattern: As the name suggests, the hammered pattern mimics the look of a surface that has been hammered by hand, creating a dimpled and uneven texture. This pattern is commonly used in architectural applications, such as wall panels, backsplashes, or decorative accents, to add a rustic and artistic touch. 4. Brushed pattern: The brushed pattern features long, uniform lines that are created by brushing the surface of the aluminum sheet with a wire brush. This pattern offers a sleek and modern appearance, making it popular for applications like kitchen appliances, signage, or interior design elements. 5. Perforated pattern: Unlike the previous patterns, the perforated pattern involves creating small holes across the surface of the aluminum sheet. This pattern is often used in applications that require ventilation, sound absorption, or decorative effects. It can be found in areas such as speaker grills, filters, or façades. These are just a few examples of the different types of patterns available for textured aluminum sheets. The choice of pattern will depend on the specific requirements of the project, including aesthetics, functionality, and durability.

- Q:How is the thickness of aluminum sheets measured?

- The thickness of aluminum sheets is typically measured using a tool called a micrometer. A micrometer is a precision instrument that includes a calibrated screw mechanism with a spindle and anvil. To measure the thickness of an aluminum sheet, the sheet is placed between the spindle and anvil of the micrometer, and the screw is turned to exert pressure on the sheet until it is firmly held in place. The measurement is then read from the micrometer's scale or digital display. Another commonly used method is a thickness gauge, which uses a set of parallel anvils to measure the thickness of the sheet. The sheet is inserted into the gap between the anvils, and the measurement is obtained by reading the scale or display on the gauge. Both methods provide accurate and reliable measurements of the thickness of aluminum sheets.

- Q:What are the different types of alloys used for anodized aluminum sheets?

- There are several different types of alloys that can be used for anodized aluminum sheets, each with its own unique properties and applications. Some of the commonly used alloys include: 1. 1000 series alloys: These alloys are primarily made of pure aluminum and are known for their excellent corrosion resistance. They are commonly used for anodized aluminum sheets in various industries, including architecture, automotive, and aerospace. 2. 5000 series alloys: These alloys contain magnesium as the primary alloying element, which provides enhanced strength and excellent weldability. They are often used for anodized aluminum sheets in applications that require high strength and resistance to atmospheric corrosion. 3. 6000 series alloys: This series of alloys is known for its excellent combination of strength, extrudability, and corrosion resistance. The most commonly used alloy in this series for anodized aluminum sheets is 6061, which is widely used in structural components, marine applications, and consumer electronics. 4. 7000 series alloys: These alloys are known for their exceptional strength and are typically used in applications that require high-performance materials. The most common alloy in this series for anodized aluminum sheets is 7075, which is widely used in aerospace and defense industries. 5. 2000 series alloys: These alloys are primarily used in applications that require high strength and excellent fatigue resistance. They are commonly used in the aerospace industry for anodized aluminum sheets. It's important to note that the choice of alloy for anodized aluminum sheets depends on the specific requirements of the application, including desired strength, corrosion resistance, and other mechanical properties.

- Q:What is the density of the 2A12 aluminum plate?

- 2.75 density. Shenzhen dexincheng metal plate is sold. Specifications are all complete.

- Q:What kind of pattern aluminium plate has?

- Aluminum alloy decorative plate: aluminum alloy perforated sound absorption boardThe aluminum alloy perforated plate is made of various aluminum alloy plates and punched by machine. Pass a round hole, square hole, round hole, square hole, triangle hole according to the needs of small hole combination. This is a new product that reduces noise and has an ornamental effect. Aluminum Alloy perforated plate material is light, high temperature resistance, corrosion resistance, fire resistance, moisture-proof, shock proof, good chemical stability, beautiful appearance, elegant color, three-dimensional sense of strong, good decorative effect, and is convenient to assemble and can be used in hotels, restaurants, cinemas, studios and other public buildings.

- Q:What are the dimensions and thickness options for aluminum sheets?

- The dimensions and thickness options for aluminum sheets can vary depending on the supplier and specific requirements. Generally, aluminum sheets are available in various dimensions, such as 4ft x 8ft, 4ft x 10ft, or custom sizes. In terms of thickness, aluminum sheets can range from as thin as 0.006 inches (0.15 mm) to as thick as 0.25 inches (6.35 mm) or even thicker for specialized applications. It is important to consult with the supplier or manufacturer to determine the exact dimensions and thickness options available for aluminum sheets.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

EN AW - 3105 Aluminium Treadplate for Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords