Industrial Aluminium Profiles For Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Industrial Aluminium Profiles For Machinery Description

Industrial Aluminium Profiles For Machinery is one semi-finished aluminium material. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel. Each profile is wrapped by the particular paper to avoid the scratching between each profile and also prevent the moisture in the air. Outside the bundle is fixed with the four wooden boards including support board vertically and base board on horizontal level. There are steel belts outside the boards to strap and tighten.

2. Specification of Industrial Aluminium Profiles For Machinery

Industrial Aluminium Profiles For Machinery | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Industrial Aluminium Profiles For Machinery

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Industrial Aluminium Profiles For Machinery

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Industrial Aluminium Profiles For Machinery

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

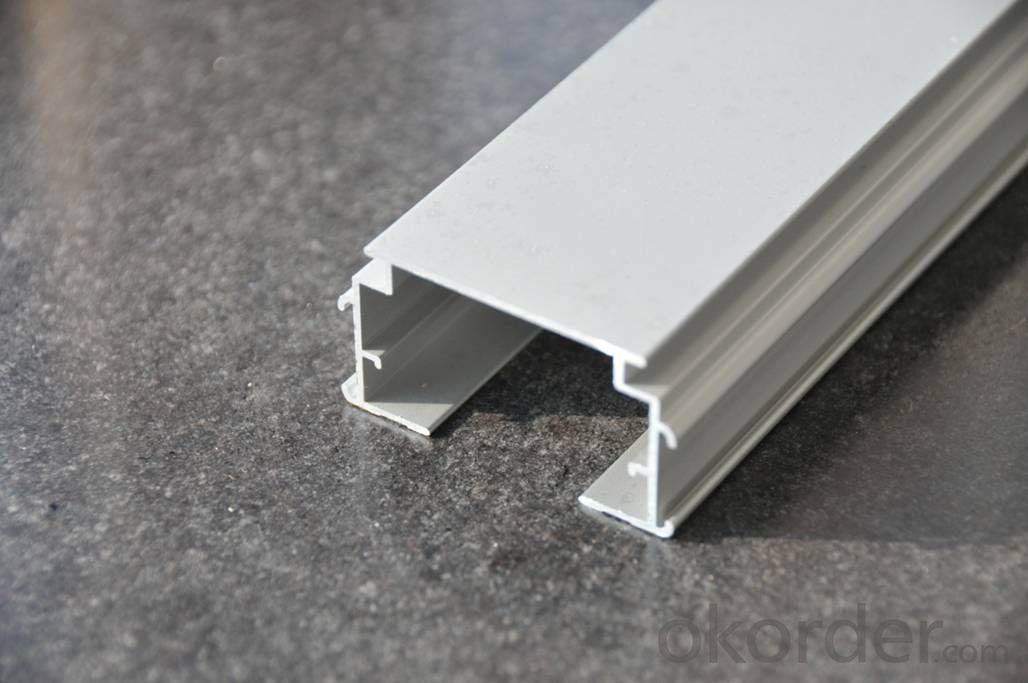

6. Image of Industrial Aluminium Profiles For Machinery

7. Package and shipping of Industrial Aluminium Profiles For Machinery

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:Aluminum profile 606360056061, T5 and T6 hardness GB, how much?

- Generally divided into Vivtorinox hardness, Rockwell hardness and Vickers hardness and webster hardness. Our enterprises are generally in accordance with webster hardness test, GB 6063-T5 8HW 6063-T6 11.5HW6005-T5 15HW 6005-T6 15HW6061-T5 15HW 6061-T6 15HWIf you need other hardness units, you can refer to the conversion

- Q:What are the standard dimensions of aluminum profiles?

- The standard dimensions of aluminum profiles can vary depending on the specific industry and application. However, there are some common standard dimensions that are widely available. In general, aluminum profiles come in a variety of shapes and sizes, including rectangular, square, circular, and custom shapes. The most common dimensions for rectangular aluminum profiles are typically between 1 inch to 6 inches in width and 1/2 inch to 4 inches in height. Square profiles often range from 1 inch to 4 inches in width and height. Circular aluminum profiles, also known as tubes or pipes, are typically available in various outer diameters ranging from 1/4 inch to 8 inches, with wall thicknesses ranging from 1/16 inch to 1/2 inch. It's important to note that these are general standard dimensions and there can be variations depending on the manufacturer and specific requirements of a project. Additionally, custom dimensions can be manufactured to meet unique specifications. When selecting aluminum profiles, it's crucial to consider the intended application and load-bearing requirements to ensure the chosen dimensions can adequately support the intended use.

- Q:Can aluminum profiles be used in railway and transportation infrastructure?

- Yes, aluminum profiles can be used in railway and transportation infrastructure. Aluminum is a lightweight and durable material that offers several advantages in these applications. One of the main benefits of using aluminum profiles in railway and transportation infrastructure is their low weight. Aluminum is significantly lighter than other materials like steel, making it easier to transport and install. This weight reduction can also lead to energy savings, as less fuel is required to move the infrastructure elements. Additionally, aluminum profiles have a high strength-to-weight ratio, meaning they can withstand heavy loads while still being relatively lightweight. This makes them suitable for various structural applications, such as supporting overhead power lines, constructing platforms, and forming the framework for bridges and tunnels. Aluminum also has excellent corrosion resistance, which is crucial in railway and transportation infrastructure exposed to harsh weather conditions and environmental elements. Aluminum profiles can withstand moisture, UV rays, and other corrosive agents, reducing maintenance requirements and increasing the lifespan of the infrastructure. Moreover, aluminum profiles can be easily fabricated and customized to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for flexibility in design and construction. Aluminum profiles can also be easily joined together using different methods, such as welding or fastening, providing ease of assembly and disassembly if needed. In conclusion, aluminum profiles can indeed be used in railway and transportation infrastructure. Their lightweight, high strength, corrosion resistance, and versatility make them an excellent choice for various structural and functional applications in these sectors.

- Q:What are the electrical insulation properties of aluminum profiles?

- Compared to plastics or ceramics commonly used in electrical applications, aluminum profiles exhibit relatively low electrical insulation properties due to their high conductivity. This attribute allows for the easy flow of electrical current. Nevertheless, with proper precautions, aluminum profiles can still be effectively utilized in electrical applications. Anodizing or coating the profiles with insulating materials like epoxy or polyurethane can significantly enhance their insulation capabilities. These coatings establish a barrier between the aluminum and the electrical current, minimizing the risk of conductivity. Moreover, aluminum profiles can be combined with other insulating materials to achieve the desired level of electrical insulation. For instance, in electrical wiring systems, aluminum conductors are frequently paired with insulating materials such as PVC or cross-linked polyethylene to ensure reliable insulation. It is crucial to recognize that while aluminum profiles may possess lower electrical insulation properties compared to other materials, they do offer other advantageous characteristics like high strength, lightweightness, and corrosion resistance. Hence, careful consideration needs to be given to the specific application and electrical requirements before selecting aluminum profiles as an electrical insulation material.

- Q:What are the advantages of using aluminum profiles in the telecommunications industry?

- Aluminum profiles offer numerous benefits for the telecommunications industry. Firstly, they possess a combination of lightweight and robust qualities, making them ideal for constructing infrastructure like antenna towers and satellite dishes. Their lightweight nature facilitates easy transportation and installation, resulting in time and cost savings. Secondly, aluminum profiles boast exceptional resistance to corrosion. This property is of utmost importance in the telecommunications industry, where exposure to harsh weather conditions and corrosive elements such as saltwater is common. Aluminum profiles can withstand these conditions without deterioration, guaranteeing the longevity and reliability of telecommunication equipment. Moreover, aluminum profiles are highly adaptable and can be easily tailored to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for the creation of intricate structures capable of accommodating different telecommunications equipment. This versatility streamlines the integration of various components and simplifies the installation and maintenance processes. Additionally, aluminum profiles possess excellent thermal conductivity, a crucial characteristic in the telecommunications industry. As telecommunication equipment generates heat during operation, effective heat dissipation is essential to prevent overheating and equipment failure. Aluminum profiles efficiently dissipate heat, ensuring optimal performance and prolonged lifespan of telecommunication devices. Finally, aluminum is a sustainable and environmentally friendly material. It is entirely recyclable, meaning that old or damaged aluminum profiles can be recycled and transformed into new products, thereby minimizing waste and reducing the environmental footprint. By incorporating aluminum profiles into their operations, the telecommunications industry can contribute to sustainability efforts. In summary, the advantages of utilizing aluminum profiles in the telecommunications industry encompass their lightweight yet sturdy nature, corrosion resistance, adaptability, thermal conductivity, and sustainability. These characteristics make aluminum profiles an excellent choice for constructing telecommunication infrastructure, ensuring reliable performance, and minimizing environmental impact.

- Q:Are aluminum profiles resistant to chemicals and acids?

- Yes, aluminum profiles are generally resistant to chemicals and acids due to their natural oxide layer that provides a protective barrier against corrosion. However, certain highly corrosive chemicals or acids may still cause damage over time.

- Q:What are the advantages of using aluminum profiles in transportation vehicles?

- There are several advantages of using aluminum profiles in transportation vehicles. Firstly, aluminum is a lightweight material, which helps to reduce the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces emissions. Additionally, aluminum profiles offer excellent strength-to-weight ratio, providing structural integrity and safety to the vehicle. Aluminum is also corrosion-resistant, ensuring durability and longevity of the vehicle. Moreover, aluminum profiles can be easily fabricated, allowing for flexible and efficient manufacturing processes. Overall, the use of aluminum profiles in transportation vehicles brings benefits such as improved fuel efficiency, enhanced safety, and increased durability.

- Q:Can aluminum profiles be used for stage and event structures?

- Yes, aluminum profiles can be used for stage and event structures. Aluminum is a lightweight and durable material that is commonly used in the construction industry for various applications, including stage and event structures. Aluminum profiles are versatile and can be easily shaped, cut, and joined together to create custom structures. They offer excellent strength-to-weight ratio, making them suitable for supporting heavy equipment and ensuring the safety of performers and audience members. Additionally, aluminum profiles can be powder-coated or anodized to provide a decorative finish and protect them from corrosion, enhancing the visual appeal and longevity of the structures. Overall, aluminum profiles are a popular choice for stage and event structures due to their versatility, strength, and aesthetic qualities.

- Q:Are aluminum profiles suitable for industrial workstations?

- Yes, aluminum profiles are suitable for industrial workstations. Aluminum is a lightweight and durable material that offers excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is easy to work with and allows for flexibility in design, making it suitable for various industrial applications. Additionally, aluminum profiles can be easily customized and adapted to meet specific workstation requirements, making them a popular choice in industrial settings.

- Q:How do you attach accessories or components to aluminum profiles?

- There are several ways to attach accessories or components to aluminum profiles. One common method is to use T-slot nuts and bolts. T-slot nuts slide into the T-slot groove on the profile and can be positioned anywhere along the length. The bolts then secure the accessory or component to the nut, creating a strong and secure connection. Another option is to use brackets or mounting plates specifically designed for aluminum profiles. These brackets usually have pre-drilled holes that align with the T-slot grooves, allowing for easy attachment of accessories. They can be fastened to the profile using screws or bolts. Additionally, there are various specialized connectors available for specific applications. Examples include corner connectors, joining plates, and hinge connectors. These connectors provide easy and reliable ways to attach accessories or components to aluminum profiles without the need for additional drilling or machining. It is important to consider the weight and load-bearing requirements of the accessories or components when choosing the attachment method. Using appropriate fasteners and connectors ensures a secure attachment and prevents any potential hazards.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Industrial Aluminium Profiles For Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords