Aluminium Extrusion Profiles For Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of Aluminium Extrusion Profiles For Motor Cylinder Shell Description

Aluminium Extrusion Profiles For Motor Cylinder Shell is one semi-finished aluminium material. It is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Extrusion Profiles For Motor Cylinder Shell

Aluminium Extrusion Profiles For Motor Cylinder Shell | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Extrusion Profiles For Motor Cylinder Shell

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Extrusion Profiles For Motor Cylinder Shell

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Extrusion Profiles For Motor Cylinder Shell

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

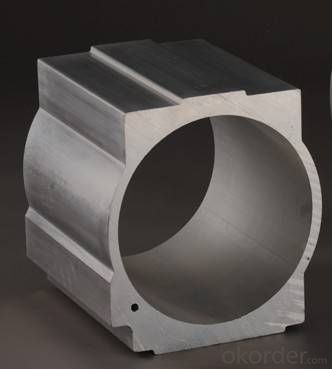

6. Image of Aluminium Extrusion Profiles For Motor Cylinder Shell

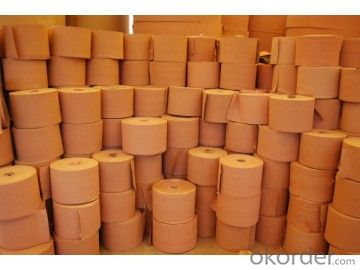

7. Package and shipping of Aluminium Extrusion Profiles For Motor Cylinder Shell

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:What are the bending radii for different aluminum profiles?

- The bending radii of various aluminum profiles can differ based on the profile's specific shape and thickness. Generally, aluminum profiles can be bent to a minimum radius, usually around 1.5 to 2 times the material's thickness. For instance, if you possess an aluminum profile with a thickness of 1mm, the minimum bending radius would be approximately 1.5 to 2mm. Similarly, if the profile's thickness is 3mm, the minimum bending radius would be about 4.5 to 6mm. It's important to note that these values are approximate and can vary depending on the particular alloy and temper of the aluminum. Moreover, the bending process itself, including the equipment and method employed, can also impact the achievable bending radii. To ensure precise bending, it is advisable to seek guidance from the manufacturer or a professional fabricator who can provide specific instructions and recommendations for bending radii based on the specific aluminum profile you are working with.

- Q:Can aluminum profiles be used in electrical enclosure manufacturing?

- Yes, aluminum profiles can be used in electrical enclosure manufacturing. Aluminum is a versatile and lightweight material that offers excellent electrical conductivity, heat dissipation, and corrosion resistance. It can be easily shaped into different profiles to suit specific enclosure designs and can provide adequate protection for electrical components.

- Q:What are the different shapes and sizes of aluminum profiles available?

- A diverse selection of shapes and sizes of aluminum profiles are accessible to accommodate different industrial and architectural needs. Some frequently encountered shapes of aluminum profiles comprise: 1. T-shape: These profiles possess a T-shaped cross-section, consisting of a horizontal top and a vertical stem. They are commonly utilized in framing and structural applications. 2. U-shape: U-shaped profiles exhibit a U-shaped cross-section, featuring two parallel horizontal arms and a connecting vertical stem. They are often employed as edge trims or decorative moldings. 3. L-shape: L-shaped profiles display a right-angle cross-section, with one arm longer than the other. They are frequently used as brackets or corner guards. 4. Square: Square profiles exhibit equivalent width and depth, resulting in a square-shaped cross-section. They offer versatility and can be applied for various purposes, such as frames, supports, or enclosures. 5. Rectangular: Rectangular profiles possess unequal width and depth, forming a rectangular cross-section. They are commonly utilized for structural intentions, like beams or frames. 6. Round: Round profiles showcase a circular cross-section and are commonly employed for applications necessitating a curved or smooth finish, such as handrails or decorative elements. Furthermore, aluminum profiles are obtainable in an assortment of sizes, ranging from diminutive dimensions suitable for lightweight applications to larger sizes for heavy-duty usage. The measurements of aluminum profiles are determined by their width, depth, and thickness, which can be personalized based on specific project requirements. In summary, the broad range of shapes and sizes of aluminum profiles allows for adaptability and versatility in design and construction, ensuring the availability of an appropriate profile for every application.

- Q:How to calculate the spraying powder of aluminium profile?

- Ask not detailed, do not know what you want to ask is how?

- Q:How to deal with the mechanical surface of aluminum profile?

- Mechanical texture removal also has mechanical methods, chemical methods can not remove deeper texture, if sand blasting effect is acceptable, you try sand blasting or shot peening

- Q:Surface treatment method of aluminium profile

- Five most common surface treatment methods for aluminum profilesFabric: Aluminum matte matte surface aluminum profile Aluminum Alloy to avoid the presence of light interference will form light environment, under the condition of building decoration in the shortcomings of its surface such as brocade as soft and delicate, very popular with the favor of the market, but the existing grinding material must overcome the uneven surface of the sand, and can see the lack of pattern.Multi color surface treatment of aluminum: the monotonous white and tinted silver has been unable to meet the good cooperation of architects and the exterior decorative tile, exterior wall latex, new stainless steel color, champagne, gold, gold, titanium series (red wine, red jujube red, black, purple etc.) plus color glass the decorative effect of the icing on the cake. These shapes must be chemically or mechanically polished and then oxidized to better effect.Electrocoating aluminium profiles: electrophoretic coating profiles of surface soft luster, can resist the erosion of acid rain, cement mortar, Japan 90% aluminum after electrophoretic coating.Powder electrostatic spraying aluminum profile: powder electrostatic spraying profile is characterized by excellent corrosion resistance, acid, alkali, salt fog is much better than oxidation coloring section.Plasma enhanced electrochemical surface ceramic aluminum profile: this type of material is the most advanced processing technology in the world today. The profile products are of good quality, but the cost is higher. It has more than 20 kinds of colors, the biggest feature is that it can be printed as needed according to the printing cloth, the surface of the section is colourful and the decoration effect is excellent.

- Q:Can aluminum profiles be used in modular construction?

- Yes, aluminum profiles can be used in modular construction. Aluminum profiles are lightweight, strong, and durable, making them an ideal choice for modular construction projects. They can be easily fabricated into various shapes and sizes, allowing for flexibility in design and construction. Additionally, aluminum profiles have excellent corrosion resistance, which is crucial for modular structures that may be exposed to harsh weather conditions. The use of aluminum profiles in modular construction also offers advantages such as reduced construction time, cost-effectiveness, and sustainability, as aluminum is a highly recyclable material. Overall, aluminum profiles provide a reliable and efficient solution for modular construction projects.

- Q:Do aluminum profiles require regular maintenance?

- Maintenance is necessary for aluminum profiles. However, the frequency and extent of maintenance depends on how they are used and the environment they are in. Although aluminum profiles are known for being durable and resistant to corrosion, they can still become dirty, grimy, and oxidized over time. To keep them clean and looking good, it is recommended to regularly clean them with mild soap or detergent and water. It is also a good idea to lubricate any moving parts, like hinges or sliding mechanisms, to ensure they operate smoothly. Additionally, it is important to inspect the profiles for any signs of damage, such as cracks or loose connections, so that any issues can be addressed before they get worse. By doing regular maintenance, the lifespan of aluminum profiles can be extended and their performance can be optimized.

- Q:Who can tell me the latest national standard for aluminum and the latest edition, -2008?

- Standard number: GB 21351-2008Standard Name: energy consumption quota for aluminum alloy building profile products per unitStandard status: currentEnglish: The, norm, of, energy, consumption, per, unit, product, of, wrought, aluminium,, alloy, extruded, architecture, profiles, for,...Date of implementation: 2008-6-1Promulgated by the Ministry of State Administration of quality supervision, inspection and Quarantine of the People's Republic of China, China National Standardization AdministrationBrief introduction: this standard specifies the Aluminum Alloy profile building energy consumption per unit product of the technical requirements, the scope of statistics and calculation method, calculation range and energy saving management measures. And the calculation and assessment of this standard applies to the enterprise energy consumption per unit product of Aluminum Alloy section building, and the consumption of the new project control.

- Q:What's the difference between aluminum oxide and electrophoresis?

- Main features: 1 aluminum oxide) has strong abrasion resistance, weatherability and corrosion resistance. 2) can form a variety of colors on the surface of the substrate, the maximum for your requirements. 3) hardness, making it suitable for all kinds of buildings, industrial materials.Main features: 1 electrophoresis aluminum) has strong film hardness and strong impact resistance. 2) has very high adhesion of film, aging is not easy to fall off. 3) has better wear resistance, weather resistance and alkali resistance than aluminum oxide. 4) surface color is rich, beautiful, with a mirror like luster effect.Aluminum electrophoresis processing in oxidized aluminum on the basis of better quality than the oxidized aluminum chip. The price is a little better.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Extrusion Profiles For Motor Cylinder Shell

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords