Steel Rolled Coil SS400 Q345 Q195 Hot Rolled Steel Coil Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

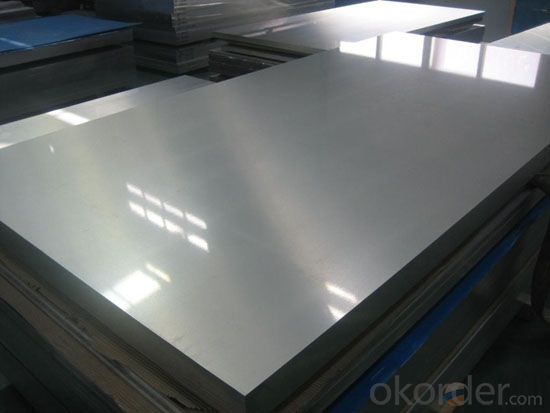

General Information of Cold Rolled Steel Sheet

The raw material of cold rolled steel sheet is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as processing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

Specifications of Cold Rolled Steel Sheet

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3) Thickness: 0.20mm - 3.0mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

Package of Cold Rolled Steel Sheet

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

Applications of Cold Rolled Steel Sheet

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q:Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q:Can the aluminum sheets be used for manufacturing solar panel frames?

- Indeed, solar panel frames can be manufactured using aluminum sheets. The solar industry frequently employs aluminum due to its lightweight nature, durability, and ability to resist corrosion. When it comes to solar panel frames, aluminum proves to be an excellent selection as it offers structural support and can endure diverse weather conditions. Moreover, aluminum is easily recyclable, thereby presenting an environmentally conscious choice for solar panel manufacturers. All in all, aluminum sheets are a fitting material for the production of solar panel frames.

- Q:What are the environmental benefits of using aluminum sheets?

- The usage of aluminum sheets is associated with numerous environmental advantages. To begin with, aluminum is a highly recyclable substance, meaning it can be recycled repeatedly without losing its quality or properties. This diminishes the need for mining and extracting new aluminum ore, which can lead to deforestation, destruction of habitats, and pollution of water and air. The recycling of aluminum sheets also demands much less energy compared to the production of new ones, resulting in reduced emissions of greenhouse gases and a smaller carbon footprint. Moreover, aluminum sheets are lightweight, making them a more sustainable option in comparison to materials like steel or plastic. Their utilization in various industries like automotive and aerospace can aid in reducing the overall weight of vehicles and aircraft, leading to improved fuel efficiency and lower emissions. This becomes particularly crucial in the context of climate change and the necessity to decrease our reliance on fossil fuels. Additionally, aluminum is resistant to corrosion, durable, and long-lasting, making it a sustainable choice for various applications. Its durability lessens the need for frequent replacements, thereby reducing waste generation. Furthermore, aluminum sheets can be employed in construction to enhance insulation, resulting in energy savings and diminished emissions of greenhouse gases. Lastly, aluminum is non-toxic and does not release harmful pollutants during its production or use. This renders it a safe material option for various applications, including food packaging and medical equipment. To summarize, the environmental benefits of using aluminum sheets include its recyclability, lightweight nature, energy efficiency, durability, and non-toxicity. By selecting aluminum sheets over other materials, we can contribute to the reduction of resource extraction, energy consumption, emissions of greenhouse gases, and generation of waste, while promoting a more sustainable and eco-friendly future.

- Q:4.0mm five bars, aluminum plate, 4 aluminum plate, one ton, how many square?

- The square and the thickness are multiplied, and then multiplied by the density is the weight, and then by weight conversion on it

- Q:What are the different methods of surface finishing for aluminum sheet?

- Aluminum sheets can undergo various surface finishing methods, each with its own distinct characteristics and advantages. Some commonly used methods include anodizing, painting, powder coating, polishing, and brushing. Anodizing is a widely employed technique that forms a protective oxide layer on the aluminum's surface. This process not only enhances the sheet's appearance but also improves its resistance to corrosion and durability. Anodized aluminum sheets are available in different colors and finishes, making them suitable for diverse applications. Painting is another frequently used method where a layer of paint is applied to the aluminum sheet to provide both decorative and protective coating. This approach allows for a wide range of colors and finishes, enabling customization and design versatility. Moreover, painting can enhance the sheet's resistance to weathering and scratches. Powder coating involves applying a dry, powdered coating to the aluminum sheet, which is then heated to create a durable and uniform layer. This technique offers excellent protection against corrosion, chemicals, and UV rays, making it ideal for applications requiring high durability and weather resistance. Polishing is a surface finishing method that employs abrasive materials to create a smooth and shiny surface on the aluminum sheet. This technique is commonly used to enhance the sheet's aesthetic appeal by eliminating imperfections and scratches. Polished aluminum sheets are often used in decorative applications where a reflective and lustrous surface is desired. Brushing is a process that gives the aluminum sheet a textured surface using abrasive brushes or pads. This method creates parallel lines or patterns on the sheet, resulting in a distinctive and attractive appearance. Brushed aluminum sheets find applications in architectural and interior design, as well as in the manufacturing of household appliances and automotive components. In conclusion, the various surface finishing methods for aluminum sheets offer a range of options to enhance their appearance, durability, and functionality. Whether it is anodizing, painting, powder coating, polishing, or brushing, each method brings unique benefits that can be tailored to specific applications and design requirements.

- Q:According to the reactivity of metals, aluminum chloride (AlCl3) will not react with copper (Cu). But I am almost sure that the copper nail I put in the aluminum chloride solution became shiny and lost its copper lust. Why did this reaction happen?

- Well done on noting unexpected observations and following up. Your copper is coated with a dull coating of copper oxide. It became shiny because aluminium salts are acidic in water and the acidity dissolves the coating to form a copper salt and leaving the shiny copper. CuO + 2H3O+ ---- Cu2+ + 3H2O The reaction to form the acidity, a hydrated hydrogen ion H+(H2O) or H3O+ is fairly complex. If aluminium chloride is dissolved in a large amount of water the solution is acidic, but this has nothing to do with formation of hydrochloric acid. The solution contains hydrated aluminium ions and chloride ions: AlCl3(s) + aq → [Al(H2O)6]3+(aq) + 3Cl -(aq) The hexaqua complex ion behaves exactly like ions of similar type formed from transition metals; the small, highly charged metal ion polarises (withdraws electron density from) the water molecules that are attached to the aluminium ion through dative covalent bonds. This makes the hydrogen atoms d+ and susceptible to attack from solvent water, which is acting as a base. The complex ion is deprotonated, causing the solution to be acidic from the formation of hydroxonium ions H3O+: [Al(H2O)6]3+(aq) + H2O(l) → [Al(H2O)5OH]2+(aq) + H3O+(aq)

- Q:Can aluminum sheets be used for battery casings?

- Indeed, battery casings can be made using aluminum sheets. Aluminum, a metal that is both lightweight and durable, possesses superb corrosion resistance, making it an ideal option for battery casings. Moreover, aluminum exhibits excellent electrical conductivity, a crucial factor for optimizing battery efficiency. Furthermore, aluminum can be easily molded and formed into diverse shapes and sizes, granting flexibility in battery casing fabrication. In conclusion, due to its advantageous characteristics, aluminum sheets are widely employed in battery casing production.

- Q:6061 what is the density of the aluminum plate?

- 6061 aluminum plate density:6061 aluminum plate is aluminum alloy, the density is calculated according to 2.9g/cm3.Calculation method:Aluminium plate weight (kg) =0.0000029 * * * * width * lengthAluminium tube weight (kg) =0.0000029 * wall thickness * (outside diameter wall thickness) * lengthFormula for weight calculation of aluminium bars (kg) =0.0000029 * radius * radius * length

- Q:Which is better, a water bottle made out of steel or one made out of aluminum?

- Aluminum

- Q:Can aluminum sheet be used for decorative purposes?

- Yes, aluminum sheet can be used for decorative purposes. Its lightweight nature, durability, and versatility make it a popular choice for various decorative applications such as signage, wall cladding, ceiling panels, furniture accents, and more. Additionally, aluminum sheets can be easily manipulated, painted, or coated to achieve different finishes, colors, and textures, allowing for endless possibilities in decorative design.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel Rolled Coil SS400 Q345 Q195 Hot Rolled Steel Coil Wholesale

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords