Domestic Color Coated Aluminium Coils for Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

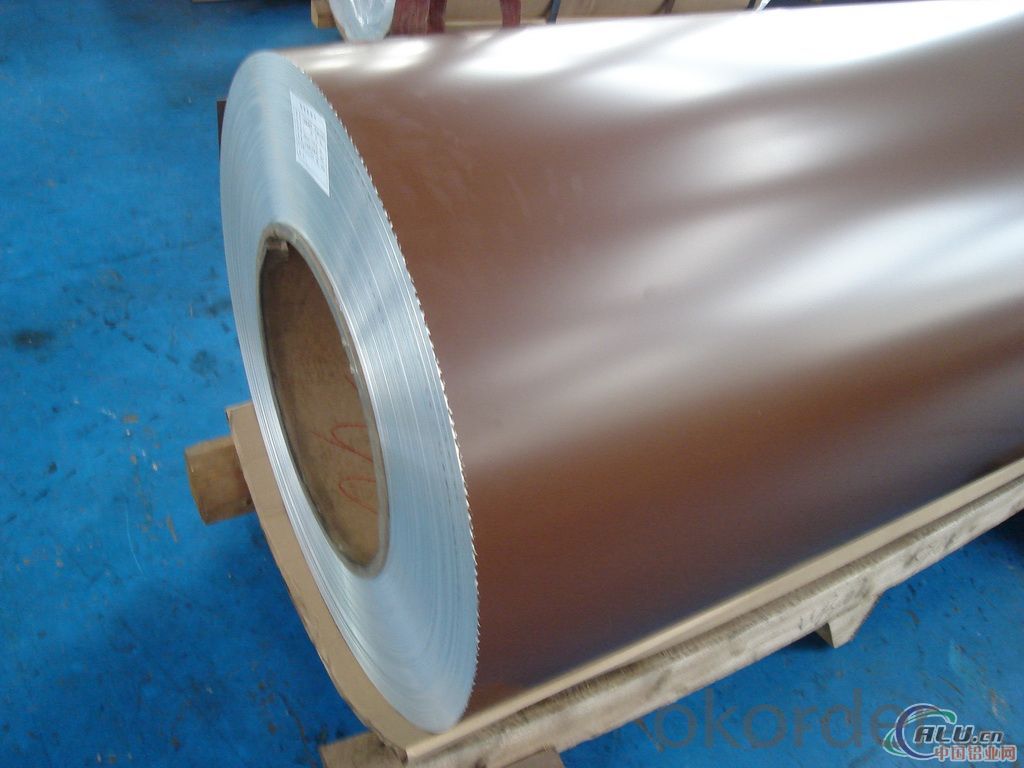

1.Structure of Domestic Color Coated Aluminium Coils for Wall Curtain

Domestic Color Coated Aluminium Coils for Wall Curtain for Composite Panel is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Domestic Color Coated Aluminium Coils for Wall Curtain

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification of Domestic Color Coated Aluminium Coils for Wall Curtain

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q:where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- This okorder ... Now for the bad news, most scrap yards DO NOT accept tabs, they try to say it's a lower grade of aluminium, which is not correct, as it is made out of the same sheet of aluminium as the can was. They just don't want to deal with it, or the people who alway's HEARD SOMEWHERE that tabs have some special value. The truth of the matter is that 1 pound of tabs (1,538 +/- tabs) is only worth about 40 cents. That's it, nothing more. Anybody who say's different is stupid, or a liar, there is no third option. Now, if you want to actually make some money, and your willing to do a little work, this is what I do. I take the tabs that i encounter in daily life, remove all damaged tabs (which are donated to McDonald's House Charities), then I sit there with a pair of needle nose pliars, and I remove that little curly thing that holds the tab to the can (which I save, and yes recycle as aluminium , over 220 pounds to date), now, count your tabs out into 1,000 count ziplock baggies. Each of these bags with 26 cents of aluminium will now sell on E-Bay for $4 plus shipping, which is $6.15 per pound. People need them for arts and crafts, I have sold literally millions on OKorder and my web site. The colored tabs are worth about 2 cents each, MONSTER and NOS tabs are worth about 5 cents each.

- Q:How do 101 aluminum sheets compare in terms of strength and durability?

- The strength and durability of 101 aluminum sheets can be evaluated based on their mechanical properties and performance characteristics. In terms of strength, 101 aluminum sheets possess moderate strength that is suitable for many applications. They have a tensile strength of around 27,000 psi (pounds per square inch) and a yield strength of approximately 21,000 psi. This indicates that they can withstand moderate amounts of stress and load without deforming or breaking. Durability-wise, 101 aluminum sheets have good resistance to corrosion, making them suitable for outdoor and marine applications. They are also highly resistant to various forms of weathering, including UV radiation and extreme temperatures. Their corrosion resistance is mainly due to the presence of a thin, protective oxide layer on the surface, which prevents further oxidation and ensures long-term durability. However, it is important to note that 101 aluminum sheets are not the most durable option available. They are not as strong or durable as some other aluminum alloys, such as 6061 or 7075, which have higher tensile and yield strengths. Hence, if a project requires exceptional strength or durability, it may be beneficial to consider using a different aluminum alloy. In conclusion, 101 aluminum sheets offer moderate strength and good durability, making them suitable for a wide range of applications. However, if the project requires higher strength or exceptional durability, it may be necessary to explore alternative aluminum alloys with superior mechanical properties.

- Q:2mm aluminum welding with oxygen welding or argon arc welding good?

- Before welding need cleaning with acetone wire and base metal surface oil and oxide layer, according to welding tungsten diameter, filler wire diameter selection of appropriate welding parameters (base current, peak current, pulse width, pulse duration, pulse frequency, duty ratio, etc.).Oxygen acetylene (or oxygen propane) flame welding, flame welding due to large heating area, directly lead to weld coarse grains, degree of weld oxidation is lower than that of AC TIG welding effect. The weld strength and mechanical properties are lower.

- Q:Trying to find the best aluminum powder I can buy for rocket engines and pyrotechnic (fireworks) uses?

- It really depends on your formula and how the aluminum is being used in the formula. Is it a part of the fuel or is an additive to the fuel for sparks?

- Q:What is the typical thermal expansion coefficient of aluminum sheets?

- The typical thermal expansion coefficient of aluminum sheets is around 23.1 x 10^-6 per degree Celsius. This means that for every degree Celsius increase in temperature, the length of an aluminum sheet will increase by approximately 23.1 millionths of its original length. It is important to note that this value can vary slightly depending on the specific alloy and processing conditions of the aluminum sheet.

- Q:Can aluminum sheets be used in the automotive industry?

- Aluminum sheets indeed find application in the automotive sector. Being a lightweight and sturdy material, aluminum offers several advantages when it comes to manufacturing automobiles. Car bodies, hoods, doors, and other structural components are commonly produced using aluminum. This helps in reducing the weight of the vehicle, resulting in improved fuel efficiency and enhanced performance. Furthermore, aluminum exhibits remarkable resistance to corrosion, making it ideal for vehicles that face harsh weather conditions. Moreover, aluminum sheets are easily formed, welded, and joined, which adds to their versatility and suitability for various automotive purposes. Consequently, the automotive industry widely embraces the utilization of aluminum sheets due to their numerous benefits.

- Q:Can the aluminum sheets be used for roofing or siding purposes?

- Yes, aluminum sheets can be used for both roofing and siding purposes. Aluminum is a popular choice for these applications due to its lightweight nature, durability, and resistance to corrosion. It is commonly used in residential, commercial, and industrial buildings for its ability to withstand harsh weather conditions, including rain, snow, and UV rays. Additionally, aluminum is a versatile material that can be easily shaped, allowing for various design options.

- Q:Does anyone know how to polish aluminum on a motorcycle that isn't too expensive to do?

- Get a $5 can of metal polish and a rag or get you one of those things that fits a drill with the really soft cloth wheel on it and polish till your hearts content. I have done the side covers, manifolds, even the carbs on old british bikes.

- Q:Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q:Can aluminum sheets be used in the aerospace industry?

- Yes, aluminum sheets are commonly used in the aerospace industry due to their lightweight, high strength, and corrosion resistance properties. They are used in the construction of aircraft structures, such as fuselages, wings, and interior components, to ensure optimal performance and fuel efficiency.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Domestic Color Coated Aluminium Coils for Wall Curtain

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords