PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Specification of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

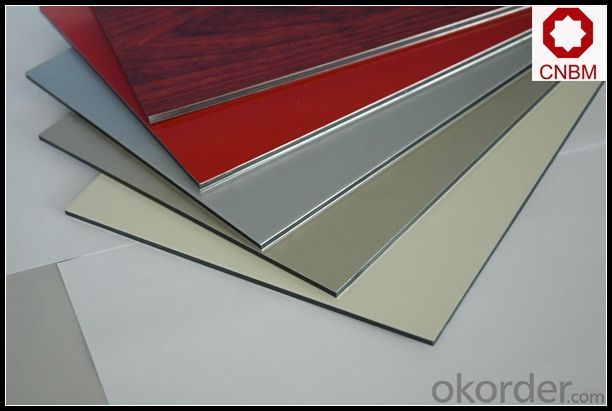

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

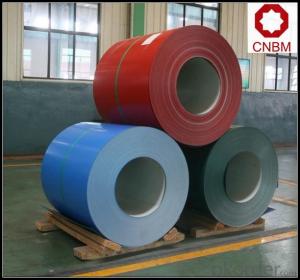

5. Image of PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factor

6. Package and shipping of ASTM B-209 Standards 3000 Series Stucco Embossed Aluminium Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q:And what are the advantages/disadvantages of steel aluminum in building cars?Which would be better for building cars?

- Similarities - They are both metals, conduct electricity and heat and deform elastically then plastically. Difference - every mechanical property there is! Density, elastic modulus (stiffness), strength and hardness are all higher for steel. But, for building cars it is about design, weight, forming, manufacturing, joining and cost. Better depends on what you are trying to acheive - cost or weight saving - and there is not a hard and fast rule as to which metal helps which. Have a look at either the Jaguar S type which is aluminium (as is the Audi A6). Most Ford cars are still steel (as are Renault). Check out the crash test results.

- Q:How is an aluminum coil made?

- An aluminum coil is made through a process called continuous casting and rolling. First, pure molten aluminum is poured into a continuous casting machine, which creates a solidified strip of aluminum. This strip is then fed through a series of rolling mills, where it undergoes multiple passes to achieve the desired thickness and shape. The rolling process also helps in improving the mechanical properties of the aluminum coil. Finally, the coil is coiled up and is ready to be used for various applications such as in construction, automotive, or packaging industries.

- Q:Can aluminum coils be used in automotive manufacturing?

- Yes, aluminum coils can be used in automotive manufacturing. Aluminum is a lightweight and durable material, making it a suitable choice for various automotive components such as body panels, engine parts, and heat exchangers. Its corrosion resistance and recyclability also make it an attractive option for the automotive industry.

- Q:Can aluminum coils be used for architectural facades?

- Yes, aluminum coils can be used for architectural facades. Aluminum is a popular material for architectural applications due to its lightweight nature, durability, and flexibility. It can be easily molded and shaped into various forms, making it suitable for creating unique and aesthetically pleasing facades. Additionally, aluminum is resistant to corrosion, making it a long-lasting choice for exterior applications.

- Q:How are aluminum coils protected against corrosion during storage?

- Aluminum coils are protected against corrosion during storage through various methods and precautions. One common method is the application of a protective coating or film on the surface of the coils. This coating acts as a barrier, preventing moisture and oxygen from coming into direct contact with the aluminum, which helps to prevent corrosion. Another method is the use of desiccants or moisture-absorbing materials. These materials are often placed inside the packaging or storage containers with the aluminum coils to absorb any moisture that may be present. By reducing the moisture content in the storage environment, the risk of corrosion is significantly minimized. In addition, proper storage conditions play a crucial role in protecting aluminum coils against corrosion. Storing the coils in a dry, well-ventilated area away from direct sunlight and other sources of moisture is essential. It is also important to ensure that the coils are stored off the ground and away from any chemicals or substances that could potentially cause corrosion. Regular inspections and maintenance are also necessary to prevent corrosion during storage. This includes checking for any signs of damage or wear on the protective coating and promptly addressing any issues that may arise. Additionally, maintaining a clean storage environment free from dust, dirt, and other contaminants will help in preserving the integrity of the protective coating and preventing corrosion. Overall, a combination of protective coatings, moisture-absorbing materials, proper storage conditions, and regular maintenance is essential for effectively protecting aluminum coils against corrosion during storage. These measures help to ensure that the coils remain in optimal condition and are ready for use when needed.

- Q:What are the energy efficiency benefits of aluminum coils?

- Aluminum coils provide numerous energy efficiency benefits that make them a preferred choice in various industries. Firstly, aluminum is an excellent conductor of heat, allowing for efficient transfer of thermal energy. This property is especially advantageous in the HVAC industry, where aluminum coils are commonly used in air conditioning and refrigeration systems. The high thermal conductivity of aluminum ensures that heat is effectively absorbed or released, resulting in faster cooling or heating processes and lower energy consumption. Additionally, aluminum coils possess exceptional corrosion resistance, which helps maintain their efficiency over time. Unlike other metals that may deteriorate due to exposure to moisture or chemicals, aluminum remains unaffected, ensuring optimal heat transfer efficiency throughout the lifespan of the coil. By preserving the coil's performance, energy losses due to reduced heat transfer are minimized, resulting in energy savings and increased system efficiency. Another significant advantage of aluminum coils is their lightweight nature. Compared to traditional copper coils, aluminum coils are significantly lighter, making them easier to handle during installation and maintenance. The reduced weight also translates into lower energy requirements for transportation, resulting in reduced carbon emissions associated with shipping. Furthermore, aluminum is a recyclable material, making it environmentally friendly and sustainable. The recycling process of aluminum requires significantly less energy compared to primary production, leading to reduced greenhouse gas emissions. By choosing aluminum coils, businesses can contribute to a more sustainable future by reducing their carbon footprint. Overall, the energy efficiency benefits of aluminum coils are vast. Their excellent thermal conductivity, corrosion resistance, lightweight nature, and recyclability make them an ideal choice for various applications, leading to reduced energy consumption, enhanced system performance, and a more sustainable environment.

- Q:Can aluminum coils be used in the production of lighting fixtures?

- Yes, aluminum coils can be used in the production of lighting fixtures. Aluminum is a lightweight and durable metal that is corrosion-resistant, making it an ideal choice for manufacturing lighting fixtures. Aluminum coils can be easily formed and shaped into various designs and sizes to meet the specific requirements of lighting fixtures. Additionally, aluminum has excellent thermal conductivity, which allows for efficient heat dissipation in lighting fixtures, ensuring optimal performance and longevity. Overall, aluminum coils provide a cost-effective and versatile solution for the production of lighting fixtures.

- Q:Are aluminum coils suitable for thermal insulation?

- No, aluminum coils are not suitable for thermal insulation.

- Q:What is the maximum temperature aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand typically ranges from 300 to 500 degrees Fahrenheit, depending on the specific alloy and application.

- Q:... of aluminum atoms?(mole = 6.022x10^23)

- Believe it or not, you have the proverbial not enough information in this problem. That's because you don't specify the thickness of the aluminum foil. You will certainly need to know that before you can determine the volume of Al and the number of atoms. You will also need the density of Al, but that's easy enough to come by. Just for grins, say the foil is 0.0020 cm thick, and the density of Al foil is 2.70 g/cm^3. If you have an Avogadro's number of Al atoms (1 mole), then you have 27.0 grams of Al (molar mass of Al). If the density of aluminum is 2.7 g/cm^3, then you have a piece of aluminum with a volume of 10.0 cm^3. V = L x W x H .... where H is the thickness of the foil You are given the width and have looked up a thickness, and have calculated the volume. So solve for length. L = V / (WH) = 10 cm^3 / (30.48 cm x 0.0020 cm) L = 164 cm You would need a section of foil 164 cm long to give you approximately 1 mol of aluminum atoms if the thickness is 0.02 mm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVDF Painted Aluminum Coil Competitive Price and BEST Manufacture and factory

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords