Hot Rolled unequal Angle Steel for insteel structrure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Description:

Specifications of Hot Rolled unequal Angle Steel for insteel structrure

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

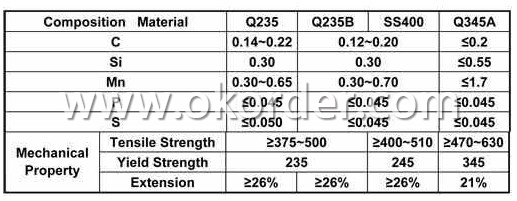

2. Invoicing on theoretical weight or actual weight as customer request3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR.

4. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

5.Sizes:

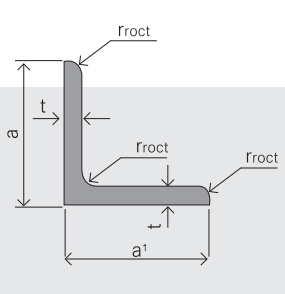

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

6. Material details:

Usage & Applications Hot Rolled Angle Steel

According to the needs of different structures, Angle can compose to different force support component. It is widely used in various building structures and engineering structures such as roof beams, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Hot Rolled unequal Angle Steel for insteel structrure

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 30MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

- Q:Can steel angles be used for equipment racks?

- Equipment racks can indeed utilize steel angles, given their versatility and strength. These angles are well-suited for a range of applications, including equipment racks, as they offer structural support and can be readily tailored to meet specific demands. Furthermore, their resistance to corrosion and ability to withstand heavy loads render them an optimal selection for equipment racks necessitating robust support for weighty apparatus.

- Q:Are steel angles suitable for architectural sculptures or installations?

- Architectural sculptures or installations can indeed benefit from the use of steel angles. These angles possess a remarkable level of versatility and durability, making them highly sought-after for the creation of intricate and visually captivating structures. The geometric nature of steel angles allows for the formation of interesting angles and shapes, thereby lending a distinctive aesthetic to architectural sculptures or installations. Moreover, the ease with which steel angles can be welded or connected together provides designers and builders with a great deal of flexibility in terms of both design and construction. The robustness and stability exhibited by steel angles also render them appropriate for outdoor installations, as they are capable of withstanding various weather conditions. In summary, architects and artists are afforded a dependable and adaptable material in steel angles, enabling them to fabricate innovative and stunning sculptures or installations.

- Q:Can steel angles be used for supports in bridges?

- Yes, steel angles can be used for supports in bridges. Steel angles are commonly used in bridge construction as they provide strength and stability. They are used as vertical supports, known as piers or columns, and as horizontal supports, known as beams or girders. Steel angles offer several advantages for bridge construction, including their high strength-to-weight ratio and their ability to withstand heavy loads and vibrations. They are also versatile and can be easily fabricated and connected, allowing for efficient and cost-effective bridge construction. Overall, steel angles are a popular choice for bridge supports due to their durability, reliability, and efficiency in supporting the weight and load of a bridge structure.

- Q:Are steel angles suitable for manufacturing support brackets for conduits?

- Yes, steel angles are commonly used for manufacturing support brackets for conduits due to their strength, durability, and ability to provide structural support.

- Q:Can steel angles be used for structural support?

- Yes, steel angles can be used for structural support. Steel angles are often used as beams, columns, or braces in construction projects due to their strength and load-bearing capabilities. They provide stability and rigidity to the structure, making them suitable for supporting heavy loads and withstanding various forces.

- Q:Are steel angles suitable for historical restoration projects?

- Yes, steel angles can be suitable for historical restoration projects. Steel angles are versatile and durable, making them an excellent choice for structural support and reinforcement in historic buildings. They can be used to restore or replicate original architectural features, such as window frames, ornamental railings, and decorative elements. Additionally, steel angles can be fabricated to match the original design and provide a seamless integration with the existing structure. However, it is important to consider the specific requirements and regulations of the historical restoration project, as some preservation authorities may have restrictions on the use of modern materials. Consulting with experts in historical restoration and obtaining necessary approvals will ensure that steel angles are used appropriately and effectively in preserving the historical integrity of the building.

- Q:Can steel angles be used for support structures?

- Yes, steel angles can be used for support structures. Steel angles are commonly used in construction and engineering industries for various purposes, including providing support and stability to structures. The L-shape of steel angles allows them to be easily bolted or welded together, making them ideal for creating strong and durable support structures. They are often used in applications such as building frames, roof trusses, bridges, and industrial platforms. Additionally, steel angles offer excellent load-bearing capacity and resistance to bending and twisting forces, making them a reliable choice for support structures.

- Q:Are steel angles suitable for high-rise buildings?

- Steel angles, otherwise referred to as L-shaped structural steel, are a fitting choice for the construction of high-rise buildings. This is primarily due to their robustness and adaptability. In particular, they provide essential support and stability to the building, particularly in cases where there is a need to transfer both vertical and horizontal loads. Moreover, steel angles possess a remarkable ability to withstand substantial stress and can easily be tailored to meet specific building requirements. Furthermore, they are cost-effective and possess a notable strength-to-weight ratio, rendering them highly suitable for high-rise construction endeavors. Ultimately, steel angles possess the vital attributes of strength, endurance, and versatility that are indispensable in the construction of high-rise buildings.

- Q:Can steel angles be used for manufacturing handrails?

- Yes, steel angles can be used for manufacturing handrails. Steel angles provide structural support and durability, making them an ideal choice for constructing handrails that need to withstand heavy loads and provide safety.

- Q:How do steel angles perform in corrosive environments?

- Steel angles exhibit good performance in corrosive environments, but their resistance to corrosion is contingent upon the type and grade of steel employed. Generally speaking, stainless steel angles and galvanized steel angles outperform carbon steel angles in terms of corrosion resistance. Stainless steel angles incorporate chromium, which generates a passive layer on the surface, thereby safeguarding against corrosion. Consequently, they possess heightened resistance to rust and other forms of corrosion, even in highly corrosive settings like saltwater or chemical plants. Galvanized steel angles, on the other hand, are steel angles that have been endowed with a zinc coating. This zinc coating functions as a sacrificial barricade, shielding the underlying steel from corrosion. In humid environments or ones exposed to moisture, galvanized steel angles excel due to their exceptional corrosion resistance facilitated by the zinc coating. Conversely, carbon steel angles are more susceptible to corrosion. In the absence of any protective coating, exposure to moisture or corrosive substances can lead to rust and corrosion in carbon steel angles. Nevertheless, there exist several methods to augment the corrosion resistance of carbon steel angles, such as the implementation of protective coatings or the utilization of corrosion inhibitors. In summary, steel angles can perform commendably in corrosive environments; however, the selection of steel grade and implementation of protective measures are pivotal for ensuring their long-term corrosion resistance. Stainless steel angles and galvanized steel angles are typically favored due to their superior corrosion resistance, while carbon steel angles necessitate supplementary safeguarding to ensure their durability in corrosive environments.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled unequal Angle Steel for insteel structrure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 150000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords