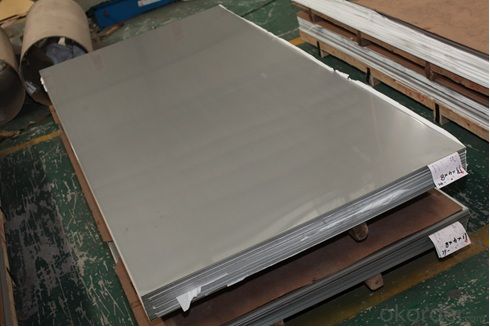

SUS316L No. 1 Finish Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Product Brief Introduction

SUS316L No. 1 Finish Stainless Steel Plate

---Stainless steel plate applies to construction field, ships building industry, petroleum,

chemical industries, war and electricity industries, food processing and medical industry,

boiler heat exchanger,machinery and hardware fields.

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: JIS: SUS 201, 202, 301, 304, 304L, 309S, 310S, 321, 316, 316L, 321, 410, 409L, 430

Thickness: 0.13mm~3.0mm,

Width: 10mm-2000mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

1. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q:How are steel strips slit into narrower widths?

- Steel strips are slit into narrower widths through a process called slitting. Slitting is typically done using a machine called a slitter, which is equipped with circular blades. The steel strip is fed into the slitter, and as it passes through the machine, the circular blades rotate and cut the strip into narrower widths. The number of blades and their positions can be adjusted depending on the desired width of the final product. To ensure accuracy and precision, the slitter is equipped with various mechanisms like tension control systems and edge guides. These mechanisms help maintain the proper tension on the strip and ensure that it remains aligned during the slitting process. After the strip is slit into narrower widths, the individual coils or strips are then rewound onto separate spools or coils. These narrower strips can be used for various applications such as in the manufacturing of automotive parts, appliances, construction materials, or even in the production of other steel products.

- Q:How are steel strips used in the production of hand tools?

- Due to their durability and versatility, steel strips find wide application in the manufacturing of hand tools. These strips are typically made from high-quality steel alloys, which offer exceptional strength and wear resistance. In the production process, steel strips are initially cut into desired dimensions and then undergo various forming operations such as bending, stamping, or rolling. This allows the strips to take on the specific shapes required for hand tool components, including blades, handles, or shafts. The flexibility of steel strips enables the production of a diverse range of tool designs to meet varied application needs. Once the components are shaped, they undergo further processing through heat treatment, which enhances their hardness and toughness. This treatment ensures that the hand tools can endure significant force, impact, and wear during use, making them highly durable and long-lasting. Steel strips are also utilized in the production of hand tool accessories, such as springs, clips, or fasteners. These components play crucial roles in enhancing the functionality and usability of the tools. For example, springs made from steel strips provide the necessary tension or pressure required for certain hand tools, like pliers or clamps. Furthermore, steel strips can be coated or plated with protective finishes, such as chrome or nickel, to enhance their corrosion resistance and improve the overall aesthetics of the hand tools. This added layer of protection ensures that the tools remain in good condition even in challenging working environments. In summary, steel strips are indispensable in the production of hand tools as they provide the necessary strength, durability, and versatility for various applications. From blades to handles, these strips enable the creation of high-quality tools that can withstand rigorous use and deliver exceptional performance.

- Q:What are the common rust prevention methods for steel strips?

- There are several common rust prevention methods for steel strips that are widely used in various industries. These methods aim to protect the steel strips from corrosion and extend their lifespan. 1. Galvanization: This method involves coating the steel strips with a layer of zinc. The zinc acts as a sacrificial anode, which means that it corrodes instead of the steel. Galvanization provides excellent protection against rust and can be achieved through hot-dip galvanizing or electroplating. 2. Coating: Applying a protective coating on the surface of the steel strips helps prevent rust formation. There are various types of coatings available, such as paint, epoxy, enamel, or powder coating. These coatings act as a barrier, shielding the steel from exposure to moisture and corrosive elements. 3. Oil or Wax Coating: Another effective method is applying a thin layer of oil or wax on the steel strips. This coating helps to create a barrier between the steel and the surrounding environment, preventing moisture from coming into direct contact with the metal. 4. VCI (Volatile Corrosion Inhibitor): VCI is a rust prevention method that involves applying chemicals or compounds that release corrosion inhibiting vapors onto the steel strips. These vapors form a protective layer on the metal surface, inhibiting the formation of rust. 5. Storage in a Dry Environment: Proper storage conditions play a crucial role in preventing rust. Keeping the steel strips in a dry environment with low humidity levels minimizes the chances of moisture condensation and rust formation. 6. Regular Maintenance: Regular inspection and maintenance of the steel strips are essential to identify any signs of rust or corrosion early on. Timely cleaning, reapplication of coatings, and addressing any issues promptly can help prevent rust from spreading and causing further damage. It is important to note that the choice of rust prevention method may vary depending on factors such as the specific application, budget, and environmental conditions. Consulting with experts or professionals in the field can help determine the most suitable rust prevention method for steel strips in a given situation.

- Q:How are steel strips used in the oil and gas industry?

- Steel strips are used in the oil and gas industry for various applications such as manufacturing pipes, tanks, and equipment used for exploration, drilling, and transportation. These strips provide strength, durability, and corrosion resistance necessary to handle the harsh conditions of the industry.

- Q:How do steel strips perform in high-temperature environments?

- Steel strips perform well in high-temperature environments due to their exceptional heat resistance and ability to maintain their structural integrity at elevated temperatures.

- Q:How are steel strips used in the manufacturing of kitchenware?

- Due to their versatility, durability, and ease of manipulation, steel strips are commonly utilized in the manufacturing of kitchenware. These strips serve as the primary material for various utensils and appliances, such as pots, pans, cutlery, and baking trays. The shaping and forming of desired products is one of the key applications of steel strips in kitchenware manufacturing. By easily cutting, bending, and molding the strips into different shapes and sizes, manufacturers can create a wide range of utensils with various functional purposes. The flexibility of steel strips enables the production of intricate designs and details, ensuring that the final product meets aesthetic and functional requirements. Furthermore, steel strips possess excellent heat conductivity, making them ideal for cookware. They efficiently distribute heat evenly across the surface, guaranteeing uniform cooking. This property is particularly important for pots and pans, as it eliminates hotspots and allows for precise temperature control during the cooking process. Moreover, steel strips used in kitchenware are typically coated with non-stick materials like Teflon or ceramic. This coating ensures that food does not adhere to the surface, making cooking and cleaning easier. It also safeguards the steel against reactions with acidic or alkaline ingredients, thereby preserving the quality and taste of the food. Additionally, the durability of steel strips ensures that kitchenware remains long-lasting and resistant to wear and tear. Steel is a robust and sturdy material capable of withstanding high temperatures and heavy use. This characteristic guarantees that kitchenware made from steel strips can endure frequent utilization, including the use of metal utensils, without warping or scratching. In conclusion, steel strips play a vital role in the manufacturing of kitchenware due to their versatility, heat conductivity, non-stick properties, and durability. They enable the production of a wide variety of utensils and appliances, ensuring that consumers have access to reliable and high-quality kitchen products.

- Q:What are the specifications for steel strips used in the production of conveyor belts?

- The production of conveyor belts requires different specifications for the steel strips, which can vary depending on the specific needs of the application. However, there are some general specifications commonly used in the industry. 1. Material: High-quality carbon steel or stainless steel is typically used for the steel strips in conveyor belts. Carbon steel is more commonly used due to its strength and cost-effectiveness, although stainless steel may be preferred in applications where corrosion resistance is crucial. 2. Thickness: The desired strength and durability of the conveyor belt determine the thickness of the steel strip. The thickness usually ranges from 0.4mm to 3mm, although thicker strips may be used for heavy-duty applications. 3. Width: The width of the steel strip is determined by the width of the conveyor belt itself. It can vary from a few centimeters to several meters, depending on the specific application. 4. Surface Finish: The surface finish of the steel strip can be plain or coated. Coatings such as zinc or chrome may be applied to enhance the strip's corrosion resistance. 5. Tensile Strength: The steel strip's tensile strength is a crucial specification as it determines the maximum load the conveyor belt can handle. Typical tensile strength ranges from 500 MPa to 1500 MPa, depending on the application. 6. Hardness: The wear resistance of the steel strip is influenced by its hardness. In high-wear applications, hardened strips are often used to improve the conveyor belt's longevity. 7. Edge Condition: The edges of the steel strip can be either slit or deburred. Slit edges are more commonly used as they provide a smoother surface for the conveyor belt to run on. It is important to note that these specifications are not exhaustive and may vary depending on the specific requirements of the conveyor belt application. For more detailed and customized specifications, consulting a steel strip manufacturer or conveyor belt supplier is recommended.

- Q:Can steel strips be used in the production of packaging materials?

- Yes, steel strips can be used in the production of packaging materials. Steel strips are commonly used in the manufacturing of various types of packaging materials, such as metal straps, bands, or seals. These packaging materials are widely used in industries like shipping, transportation, and warehousing to secure and bundle different types of goods and products. Steel strips provide excellent strength and durability, making them suitable for heavy-duty applications. Additionally, they offer resistance to corrosion and can withstand rough handling, ensuring that the packaged items remain secure and protected during transit.

- Q:How are steel strips used in the manufacturing of lighting fixtures?

- Steel strips are used in the manufacturing of lighting fixtures to provide structural support and stability to the fixtures, as well as to form the base or frame of the fixture. The steel strips are often shaped, bent, or welded to create the desired design and shape of the lighting fixture.

- Q:What are the environmental implications of steel strip production?

- The environmental implications of steel strip production are significant. The production process involves high energy consumption and the emission of greenhouse gases, contributing to climate change. Steel strip production also generates large amounts of waste, such as slag and dust, which can contaminate soil and water if not properly managed. Additionally, the extraction of raw materials for steel production, such as iron ore and coal, can lead to habitat destruction and biodiversity loss. Overall, efforts should be made to improve the efficiency of steel production and implement sustainable practices to minimize its environmental impact.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

SUS316L No. 1 Finish Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords