Aluminium Strips for Window Use and Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Aluminium Strips for Window Use and Decoration

l Product Specification

Description | 1060 aluminum strips |

Alloy | 1050; 1060; 1070; 1100; 1200; 1235; 3003; 3105; 3A21; 5052; 5754; 5083; 5A02; 5A03; 5A05; 8011 |

Temper | O; H12; H14; H16; H18; H22; H24; H26 |

Thickness (MM) | 0.1~6.0 |

Width (MM) | 20~2300 |

Inner Dia (MM) | 75; 150; 200; 300; 400; 505 |

Application | Construction, Decoration, Automobile, Electronics, Machinery, Boat Construction, Aeronautics&Astronautics, Cookware, Packing etc. |

Chemical Composition GB/T 3190-1996

Aluminum Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Other Composition | Others | Al | |

Per | All | ||||||||||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | V0.05 | 0.03 | - | 99.60 |

ALUMINIUM Coils used for celling, decorate, ACP,Curtain Wall,Roofing Sheet, PC base, radiator,cookware,deep drawing and more.

- 1 series Aluminum Coils temper: O-H112

- 1 Series Aluminum Coils Alloy: 1100/1050/1060/1200/1035/1070

-Thickness: 0.5-10mm

-Width:200-2500mm

-Length:12m Max.

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 15 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

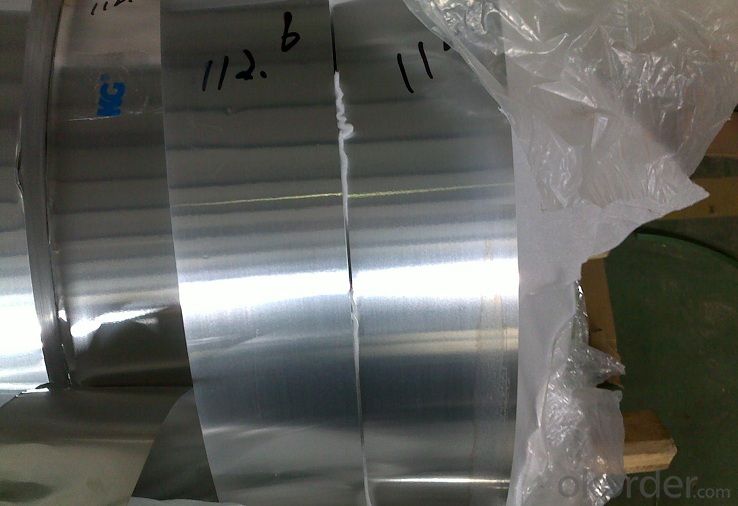

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q:I'm having trouble with another chem problemAluminum sulfide reacts w/water to form aluminum hydroxide and hydrogen sulfide. Write the balanced chemical equation for this reaction and find how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide.I already found the balanced equation but I need help on finding how many grams of aluminum hydroxide are obtained from 14.2 g of aluminum sulfide. Can someone please explain how it's done?

- No way!! because of the fact inspite of the bat, the helmet and the shin guards the undergo is plenty larger than a human and is going to basically get mad from the bat and kill you. Nope $800,000 isn't something for that!

- Q:Are aluminum coils compatible with other building materials?

- Yes, aluminum coils are compatible with other building materials. Aluminum is a versatile material that can be used in conjunction with various building materials such as steel, concrete, glass, and wood. It is commonly used in construction projects for roofing, cladding, and façade systems, as well as in HVAC and electrical applications. Aluminum's corrosion resistance and lightweight properties make it a preferred choice for integration with other building materials.

- Q:How are aluminum coils protected during shipping?

- Aluminum coils are protected during shipping through various methods to ensure their safety and prevent any damage. One common method is the use of protective packaging materials such as bubble wrap, foam, or corrugated cardboard. These materials are used to wrap the coils and create a cushioning effect, absorbing any impact or vibration that may occur during transportation. In addition to protective packaging materials, aluminum coils are often placed in sturdy shipping containers or crates. These containers are designed to provide extra security and stability during transit, minimizing the risk of the coils being jostled or bumped. Moreover, in some cases, aluminum coils are secured with strapping or banding to keep them in place and prevent shifting or movement during transportation. This helps to maintain the integrity of the coils and minimize the risk of damage caused by rubbing against other objects. Furthermore, shipping companies may also use air-bag systems or dunnage bags to fill any empty spaces within the shipping container. This further reduces movement and provides an additional layer of protection for the coils. Overall, the protection of aluminum coils during shipping involves a combination of packaging materials, secure containers, and preventive measures to ensure their safe arrival at their destination.

- Q:Can aluminum coils be used in solar energy systems?

- Yes, aluminum coils can be used in solar energy systems. Aluminum is a commonly used material in the construction of solar panels and solar energy systems due to its excellent properties. Aluminum coils are lightweight, durable, and have excellent thermal conductivity, making them ideal for transferring heat away from the solar cells. Additionally, aluminum is resistant to corrosion, which is crucial for outdoor applications where solar panels are exposed to various weather conditions. The use of aluminum coils in solar energy systems helps improve the overall efficiency and lifespan of the panels, contributing to the effectiveness and sustainability of solar energy generation.

- Q:Can aluminum coils be used in the production of chemical storage tanks?

- Yes, aluminum coils can be used in the production of chemical storage tanks. Aluminum is a durable and corrosion-resistant material, making it suitable for containing various chemicals. Additionally, its lightweight nature allows for easier handling and installation of the storage tanks.

- Q:How are aluminum coils used in the production of consumer electronics?

- Consumer electronics rely heavily on the utilization of aluminum coils for a multitude of purposes. A prevalent example is their application in the creation of heat sinks. These heat sinks are instrumental in dissipating the heat produced by electronic components like microprocessors, thus averting overheating and ensuring optimal performance. To achieve this, aluminum coils are often molded into fins or plates and subsequently affixed to these components, exploiting the exceptional thermal conductivity of aluminum. Another way aluminum coils find use in the realm of consumer electronics is through their incorporation into electromagnetic shields. The primary objective of these shields is to obstruct or redirect electromagnetic interference (EMI) generated by electronic devices. Given aluminum's exceptional electrical conductivity, it is an ideal material for the construction of these shields. Manufacturers shape the coils into diverse forms and sizes in accordance with the specific requirements of the electronic device, seamlessly integrating them into the overall design to minimize EMI. In addition, aluminum coils serve a vital purpose in the production of electrical connectors and wiring within consumer electronics. Aluminum's lightweight nature, durability, and commendable electrical conductivity make it an excellent choice for these applications. Manufacturers frequently process and shape the coils into thin, flexible strips or wires that can be effortlessly integrated into the electronic circuitry. To summarize, the indispensability of aluminum coils in the manufacturing process of consumer electronics is undeniable. Their ability to function as heat sinks for thermal management, electromagnetic shields for EMI protection, and electrical connectors and wiring for efficient electrical conductivity underscores their versatility. Coupled with their outstanding thermal and electrical properties, aluminum coils are an integral component in the production of a diverse range of consumer electronic devices.

- Q:Can aluminum coils be used in chemical processing plants?

- Yes, aluminum coils can be used in chemical processing plants. Aluminum is a versatile and widely used material in various industries, including chemical processing. It has excellent corrosion resistance properties, which make it suitable for handling and transporting various chemicals. Aluminum coils can be used in heat exchangers, condensers, evaporators, and other equipment in chemical processing plants. Additionally, aluminum coils offer lightweight and high thermal conductivity, which allows for efficient heat transfer and energy savings. However, it is important to consider the specific requirements and compatibility of the chemicals being processed to ensure that aluminum coils are suitable for the intended application.

- Q:What is the structure of Aluminium Chloride at 180, 192.4 (melting point) and 200 degrees celsius? When does it exist as an ionic lattice and when as a Al2Cl6 dimer?

- Aluminium chloride sublimes (turns straight from a solid to a gas) at about 180°C. If it simply contained ions it would have a very high melting and boiling point because of the strong attractions between the positive and negative ions. The implication is that it when it sublimes at this relatively low temperature, it must be covalent. The dots-and-crosses diagram shows only the outer electrons. Hope that help Check here for more information; www.chemguide .uk/atoms/bonding...

- Q:What are the precautions to be taken while handling aluminum coils?

- To ensure safety and prevent potential accidents or damage, there are several precautions that should be taken when dealing with aluminum coils. First and foremost, it is essential to wear the appropriate personal protective equipment (PPE), including gloves, safety goggles, and protective clothing. This gear will help safeguard against cuts, abrasions, and exposure to chemicals. It is also crucial to handle aluminum coils with care to avoid any harm or deformation. Dropping or mishandling the coils can compromise their structural integrity and potentially lead to injuries. Furthermore, one must be mindful of the weight of the coils and employ proper lifting techniques. If the coils are too heavy to lift safely, seeking assistance or utilizing mechanical lifting equipment is imperative to prevent strain or injury. Moreover, aluminum coils should be stored and transported securely and stably. They should be placed on a flat and even surface and adequately secured to prevent any movement or rolling. During transportation, it is essential to ensure that the coils are well protected against potential damage or external forces. In addition, maintaining a clean work area, free from clutter or obstacles that may cause accidents, is of utmost importance. Any spills or leaks should be promptly cleaned up to prevent slips or falls. Lastly, it is crucial to adhere to all safety guidelines and procedures provided by the manufacturer or employer. This includes understanding the specific properties and hazards associated with aluminum coils and following any recommended handling or storage instructions. By following these precautions, individuals can minimize the risk of accidents, injuries, and damage while handling aluminum coils.

- Q:What are the vibration damping properties of aluminum coils?

- Aluminum coils have excellent vibration damping properties, making them an ideal choice for various applications that require vibration control. Due to their high stiffness and low density, aluminum coils effectively absorb and dissipate vibrations, reducing the amplitude and frequency of oscillations. This vibration damping ability is beneficial in industries such as automotive, aerospace, and electronics, where minimizing vibration is crucial for performance, durability, and overall user experience. Additionally, aluminum coils' ability to dampen vibrations helps to reduce noise levels, leading to quieter operations and environments. Overall, aluminum coils' vibration damping properties contribute to improved product performance, increased safety, and enhanced user comfort.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminium Strips for Window Use and Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords