Aluminum Boat for Fishing with Different Size

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Brand Name: | Allheart | Model Number: | HT625 |

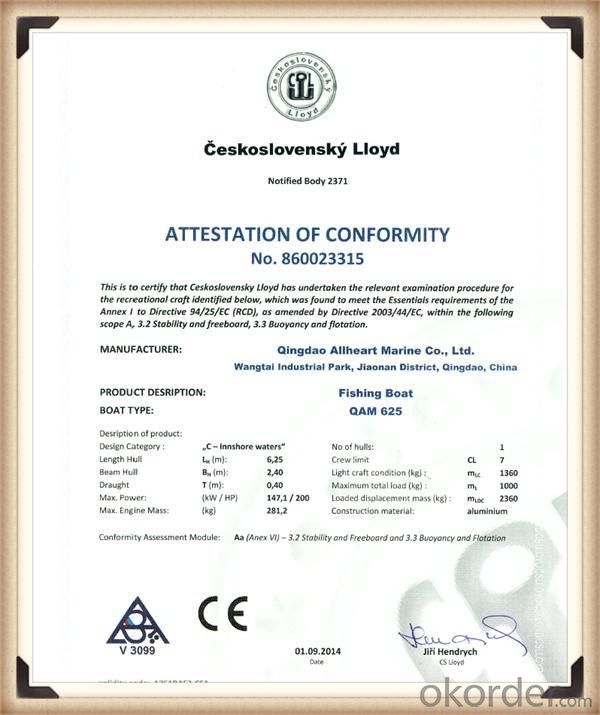

| Hull Material: | Aluminum | Certification: | CE | Capacity (Person): | 10 |

| Length: | 6.25-8m | color: | optional |

Packaging & Delivery

| Packaging Details: | 1)Fishing Boat package according to export standard 2)Fishing Boat package based on seaworthy standard 3)Special package as customer's request |

| Delivery Detail: | within 45 days after 30% deposit |

6.25m cuddy cabin | ||

SPECIFICATIONS | STANDARD FEATURES | STANDARD FEATURES |

Length of Hull: 6.25m | 3 Years Warranty | Seat: Ocean Pro & box storage |

Beam: 2.3m | Rear Ladder | Cleat on Front Deck |

Depth: 1.45m | Windscreen | Floor: Front Casting Platform |

Sides:4mm | Rod Holders (4) | Rail: Transom & Cabin Grabrail |

Bottomsides: 5.00mm | Bollard/Boweye | Rail:Long Side Rails & Low Bowrails |

Topsides: 4.00mm | Anchorwell | Transducer Brackets x 2 |

Transom Material: 5.00mm | Cabin and hard Top | Seat: Cabin Cushions |

Transom Shaft Length: L/L | Double chimes | Cleat On Transom Corners |

Weight (boat only):1155kg | Carpet wooden floor | Twin Battery Box & Switch |

Rec. HP: 150hp | TMC bilge pump | Underfloor Fuel Tank 200 Litres |

Max. HP: 200hp | Under the floor flotation | Seat: Folding Rear Lounge |

Main Motor Weight: 315kg | Cutting Board (Alloy) | fishing tank 60L |

umber of People (Level): N/A | Self Drain Floor Treadplate | Trim Tabs |

Number of People: 8 | Side Pockets (2) | Bait tank 30L |

FAQ

Q: What models do you have available?

A: We currently offer the following layouts for the 498 Series:

Angler 498A - Side Console Boat

Bay Fisher 498F - Center Console Boat

Bay Rover 498R - Runabout Boat

Sports Cuddy 498S - Cuddy Cabin Boat

We also offer 4.6m versions of these boats, they are identical except for the twin rear swimming platforms.

Q: I want to see the boats in person, where can I find them?

A: We have showrooms in Japan (Osaka), Australia (Sydney, Brisbane and Melbourne), and other countries. Please see our website at www.MorningstarBoats.com for a complete list. We are also happy to organize factory tours for you if you would like to come to Taiwan for a visit.

Q: Could you pre-install outboard engines for me?

A: Yes, we can provide Mercury and Evinrude outboards, from 40HP to 115HP.

Q: Could you provide boat trailers?

A: Yes, we have boat trailers specially designed for our aluminum boat hulls.

Q: Do I need drainage for my boat?

A: Aluminium floor without drainage is like most small boats, when you moor it in the harbour and it keeps raining, water will start to accumulate. Once the water level from under the deck is high enough, the automatic bilge pump will be triggered and starts pumping out water.

Our Services

We provide the following products:

14ft, 15ft, 16ft and 17ft aluminum luxury boats (4.6m ~ 4.98m). This is our most popular range.

10ft, 11ft, 12ft, and 13ft small aluminum fishing boats (car toppers and open boats, 3.2m ~ 4.1m) Guranteed low prices!

5.5m Rigid-Hulled Inflatable Boats (RIBs) with aluminum hulls

We provide many customization options.

Contact us NOW for the best boat money can buy!

- Q:How does the formability of aluminum sheet vary with different alloys?

- Variations in chemical composition and mechanical properties result in significant differences in the formability of aluminum sheet among different alloys. To enhance specific characteristics like strength, corrosion resistance, and formability, aluminum alloys are typically combined with elements such as copper, manganese, magnesium, and zinc. Aluminum alloys like the 1xxx series (pure aluminum) and the 3xxx series (manganese alloyed) are highly formable and commonly used for deep drawing applications. These alloys can be shaped into complex forms without cracking or tearing. In contrast, alloys with higher strength properties, such as the 2xxx series (copper alloyed) and the 7xxx series (zinc alloyed), generally have reduced formability. Although these alloys are often used in structural applications where strength is crucial, they require careful handling and processing to avoid defects during forming. Alloys in the 5xxx series (magnesium alloyed) offer a good balance of formability and strength. They are widely used in industries like automotive and aerospace, as they can be easily formed into different shapes while providing sufficient strength and corrosion resistance. It's important to note that the formability of aluminum sheet is not solely determined by the alloy composition. Other factors such as sheet thickness, forming temperature, and the specific forming process employed (e.g., deep drawing, bending, stretching) also influence formability. These factors interact with alloy properties to affect the formability characteristics of aluminum sheet. Therefore, careful selection of the appropriate alloy and process parameters is essential to achieve the desired formability for specific applications.

- Q:What are the electrical conductivity properties of aluminum sheets?

- Aluminum sheets are equipped with exceptional electrical conductivity characteristics. With its low electrical resistance, aluminum finds extensive usage in diverse electrical applications. It boasts a high conductivity rating, marginally lower than that of copper, rendering it an effective electricity conductor. This attribute enables aluminum sheets to efficiently transmit electrical current with minimal energy wastage. Consequently, aluminum is extensively employed in power transmission lines, electrical wiring, and electrical connectors. Moreover, aluminum's conductivity renders it suitable for applications requiring heat dissipation, such as heat sinks in electronic devices. In general, aluminum sheets are renowned for their favorable electrical conductivity, making them a preferred choice in numerous electrical and electronic applications.

- Q:I need help with this question for a report i'm doing, it's about recycling aluminium, please could you give me some reasons why to recycle aluminium and eg.saves energy, and how it does eg. saves energy by...Thanks a lot this will help me loads.P.S this is just a report for my science project.

- Well aluminium is a common metal and throwing it away fills up land fills. Recycling the metal means less mining and ripping up the earth.

- Q:What is aluminum sheet?

- Aluminum sheet refers to a thin, flat piece of aluminum that is commonly used in various industries for its lightweight, durable, and corrosion-resistant properties. It can be easily bent, cut, and formed into different shapes, making it versatile for applications such as construction, automotive, aerospace, and packaging.

- Q:What paint is better to paint on the brushed aluminum sheet? Simple process and good adhesion!

- Car paint is better, you can go to the auto paint repair department to buy a little, but pay attention to two points: 1., the oil on the aluminum alloy solvent cleaning. 2. can not spray thick, otherwise it will rise.

- Q:Are aluminum sheets suitable for aerospace fuel tanks?

- Aerospace fuel tanks can indeed utilize aluminum sheets. In the aerospace industry, aluminum is widely employed because of its lightweight yet robust characteristics. Its strength-to-weight ratio is commendable, rendering it an ideal choice for fuel tanks that must endure the forces of flight while minimizing the aircraft's overall weight. Moreover, aluminum's resistance to corrosion is pivotal for aerospace fuel tanks, considering their exposure to diverse fuels and environmental conditions. Furthermore, aluminum's ease of fabrication and widespread availability make it a cost-efficient option for aerospace applications. In summary, aluminum sheets are a fitting material for aerospace fuel tanks due to their strength, lightweight nature, corrosion resistance, and cost-effectiveness.

- Q:is general aluminum sheet fire-proof?

- aluminum is a kind of silver white metal,melting point:660.4℃, boiling point: 2467℃,density: 2.70 g/cm?,very light, about 1/4 of iron's density.it has low hardness and good ductility, which makes it suitable for being pulled into threadlets or pressed into aluminum foils, and the later is usually used for packaging candy and cigarette. it has good electrical and temperature conductivity. it's used for the manufacture of electric wire and cable in electric power industry, and for the manufacture of cooker in daily life bined with the magnesium,copper,zinc,tin,manganese,chromium,zirconium,silicon and other elments,it can formulate various alloys that is broadly used for the manufacture of airplane,car,ship, materials of daily living equipment and the doors and windows of construction industry.aluminum is one of the best reflectors of heat and light, so it is used as thermal insulation material and the manufacture of reflecting mirror in the reflecting telescope.now, what do you think about it? the answer is certainly nonfireproof.

- Q:To rephrase- in our physics class we found that a simple bar magnet wouldn't attract to an aluminum gutter nail, but our teacher told us to find out whether or not any magnet could lift up the aluminum material. If you answer please give a reference or source, or at least an idea on how to go about researching this, all help appreciated, thanks and God Bless!

- Aluminum Magnet

- Q:What are the different methods of surface coating aluminum sheets?

- There are several methods of surface coating aluminum sheets, each with its own advantages and applications. The most commonly used methods include anodizing, powder coating, and painting. Anodizing is a process that creates a durable and corrosion-resistant layer on the aluminum sheet's surface. It involves immersing the sheet in an electrolyte solution and passing an electric current through it. This creates an oxide layer that can be dyed to achieve various colors. Anodized aluminum sheets are commonly used in architectural applications, as well as in the automotive and aerospace industries. Powder coating is another popular method that involves electrostatically applying dry powder onto the aluminum sheet's surface. The sheet is then heated, causing the powder to melt and form a durable and protective coating. Powder coating provides excellent resistance to chemicals, UV rays, and harsh weather conditions. It is commonly used in industries such as construction, automotive, and electronics. Painting is a traditional method of surface coating aluminum sheets, where a liquid paint is applied onto the surface using brushes, rollers, or spray guns. This method allows for a wide range of colors and finishes to be achieved. Painted aluminum sheets are commonly used in applications where aesthetics and customization are important, such as signage, architectural facades, and interior design. Other methods of surface coating aluminum sheets include cladding, laminating, and adhesive bonding. Cladding involves attaching a different material, such as stainless steel or copper, to the aluminum sheet's surface. Laminating involves bonding a protective film onto the sheet's surface to enhance its durability and appearance. Adhesive bonding involves applying a layer of adhesive onto the sheet's surface and then bonding a different material or coating onto it. Overall, the choice of surface coating method for aluminum sheets depends on the specific requirements of the application, including factors such as durability, aesthetics, corrosion resistance, and cost.

- Q:Can aluminum sheet be anodized?

- Yes, aluminum sheet can be anodized. Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum, enhancing its durability, corrosion resistance, and aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Aluminum Boat for Fishing with Different Size

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords