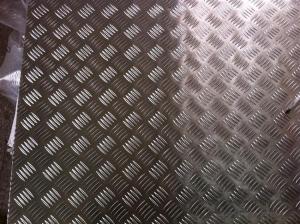

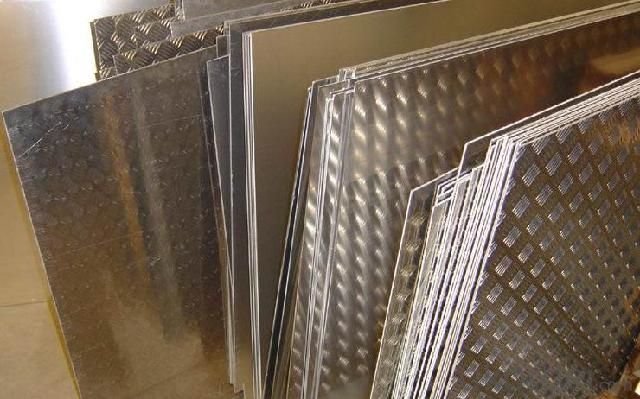

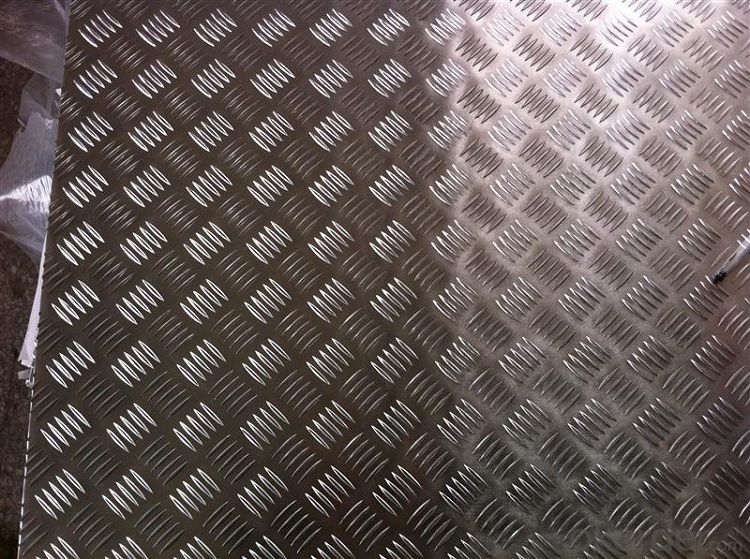

Embossed Aluminum Sheet for Treadplate/ 5052 Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Embossed Aluminum Sheet for Treadplate/ 5052 Aluminium Sheet

l Production Introduction

| Material | 1000 series: 1050. 1070. 1100 2025. 2117. 2218. 2618. 6000 series: 6005. 6011. 6053. 6351. 6061. 6101. 6151. 6201. 6261. 6262. 6063. 6463. 6066.6070 7000series: 7001. 7005. 7072. 7075. 7076. 7175. 7178. 7079 8000 series: 8011, 8021, 8079 etc |

| Standard | GB/T3618-2006 |

| Certification | ISO9001, ISO9001:2000 |

| Temper | T4,T5,T6,H111,H112 |

| Surface treatment | Polished,Mill Finished,anodized or power sprayed |

| Features | High weather resistance anti scratch anticorrosion and good weather resistance subtle edges and elegant appearance and easy processing and installation high brightness and hardness |

| Resolution | 2%-98% |

| Advantages | 1)Excellent machining properties 2)Suited to marine and low temp applications |

| Note | If you have any other question,welcome for your consultation |

l Packaging & Delivery

Packaging detail: First, plastic cloth; Second, Pearl Wool; Third, wooden cases with dry agent, without fumigation, wooden pallets

Delivery detail: Within 25days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

Aluminium treadplate is a popular product in CNBM. With best quality and service, we have won reputation around the world.

l CNBM World Wide

l Product Images and Application

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

- Q:Can aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a commonly used material in marine applications due to its excellent corrosion resistance properties and lightweight nature. It can withstand the harsh conditions of saltwater, making it suitable for boat building, marine structures, and other marine-related uses.

- Q:Whether its strong or not, im looking to get grime like stains out of my aluminum rims. It looks like they can be worked out after time, but i dont think i want to risk acidic products because im not 100% sure if theres a clear coat (i have eagle 077s if that helps!). I have read weird ideas from buffing with baby oil to brake cleaner since its super strong but dont wanna tear up my nice new wheels! Any input is greatly appreciated

- Brake cleaner will stain. You need to go to a local auto parts store, like Pep Boys, or Autozone and get a container of Mother's aluminum wheel cleaner and polish. Then go into the aisle with the rags and get a bundle of terry towels and a bundle of baby diaper towels. You will need to use the cleaner/polish on the terry towels first and work in a circular motion, and don't be afraid to apply pressure. You will start to see the cleaner working when it starts turning black, DONT QUIT YET, continue working in a circular motion, and keep at it. After you are happy with the look of the aluminum use the baby diaper towels and wipe them clean in a circular motion also. You may have to repeat to get the desired effect, but in no time your wheels will look like new (or even better)! I have personally hand polished out many small parts, and even the radiator in my 63 impala (which was raw aluminum) with this stuff and it really works.

- Q:Can aluminum sheet be used for cookware?

- Indeed, cookware can indeed employ aluminum sheets. Aluminum, being renowned for its superb heat conductivity, facilitates even heat dispersion and rapid heating. It possesses the attributes of being lightweight, long-lasting, and impervious to rust and corrosion. Moreover, aluminum cookware is reasonably priced and comparatively effortless to maintain. Nevertheless, pure aluminum proves to be a malleable metal, thus necessitating its amalgamation with other substances such as stainless steel or nonstick coatings to fortify its endurance and nonstick qualities.

- Q:What are the different types of surface treatments for aluminum sheets in the marine industry?

- In the marine industry, aluminum sheets are widely used due to their lightweight, corrosion-resistant properties. To enhance the durability and performance of aluminum sheets in marine environments, various surface treatments are employed. These treatments provide an additional layer of protection against corrosion, oxidation, and other forms of wear and tear. Some of the different types of surface treatments for aluminum sheets in the marine industry include: 1. Anodizing: Anodizing is a common surface treatment for aluminum sheets. It involves creating an oxide layer on the surface of the aluminum through an electrochemical process. This oxide layer adds strength, improves corrosion resistance, and can also be dyed to provide aesthetic appeal. 2. Powder coating: Powder coating is a popular method to enhance the appearance and durability of aluminum sheets. It involves applying a dry powder to the surface of the aluminum and then heating it to create a protective coating. Powder coating provides excellent resistance to corrosion, UV rays, and scratches. 3. Chromate conversion coating: Chromate conversion coating, also known as chemical film coating or chromating, involves immersing the aluminum sheets in a solution containing chromate compounds. This process forms a thin layer of chromate conversion coating on the surface, which enhances corrosion resistance and provides a good base for subsequent painting or bonding. 4. Paint coating: Applying a paint coating to aluminum sheets is another surface treatment method in the marine industry. Paint coatings not only enhance the appearance but also provide a protective layer against corrosion, saltwater, and other harsh environmental conditions. Epoxy or polyurethane-based paints are commonly used for marine applications. 5. Mechanical treatments: Mechanical treatments such as brushing, grinding, or polishing can be performed on aluminum sheets to improve their surface finish. These treatments remove impurities, smoothing out any imperfections and enhancing the overall appearance of the aluminum surface. Each of these surface treatments has its own advantages and is chosen based on the specific requirements of the marine application. By selecting the appropriate surface treatment, manufacturers can ensure that aluminum sheets meet the necessary performance and durability standards in the demanding marine industry.

- Q:Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable metal, which means it can be easily shaped and bent without fracturing or breaking. However, the degree of bendability may vary based on the thickness and alloy composition of the aluminum sheet.

- Q:What are the different methods of cutting aluminum sheets?

- There are several methods that can be used to cut aluminum sheets, depending on the specific requirements and the thickness of the material. Some of the most commonly used methods include: 1. Shearing: This method involves using a shearing machine to cut straight lines in the aluminum sheet. The machine applies a force to a blade, which then cuts through the material. Shearing is a quick and efficient method for cutting aluminum sheets, especially for thinner gauges. 2. Sawing: Sawing is another common method used to cut aluminum sheets. It involves using a circular saw or a bandsaw with a special blade designed for cutting metal. This method is ideal for thicker aluminum sheets, as it allows for more precision and controlled cuts. 3. Laser cutting: Laser cutting is a highly precise and efficient method for cutting aluminum sheets. It uses a concentrated beam of light to melt and vaporize the material, creating a clean and smooth cut. Laser cutting is particularly useful for intricate designs or complex shapes. 4. Waterjet cutting: Waterjet cutting involves using a high-pressure stream of water mixed with abrasive particles to cut through aluminum sheets. This method is suitable for various thicknesses and can achieve precise cuts without generating heat. Waterjet cutting is often used for thicker aluminum sheets or when high precision is required. 5. Plasma cutting: Plasma cutting uses a high-temperature plasma torch to melt and cut through aluminum sheets. The torch generates an electric arc that ionizes the gas, creating a plasma state. This method is versatile and can cut through different thicknesses of aluminum sheets, but it may result in rougher edges compared to laser or waterjet cutting. It is important to consider the specific requirements of the project, such as the desired cut quality, speed, and complexity, when choosing the most appropriate method for cutting aluminum sheets.

- Q:My new home has a mix of copper and aluminum wiring. My mother used a shop vac in one of the recepticles last week and blew two of them in my bedroom. Then this weekend my brother was replacing my exhaust fan in the bathroom and that proceeded to blow the entire bedroom and bathroom including ceiling fans, lights and all recepticles. Does anyone have any ideas?

- Many older homes in Las Vegas had aluminum wires before they figured it out, the wire contracts and expands with the heat and, what does Las Vegas have, heat of course. Other places have the same thing. It was a War thing during WW2 for copper wire, use Aluminum instead but, now, it raising heck with the homes that have it. I've seen the entrance boxes where the wires come in and the wires are a good half inch away from the hold downs, when you come back in the morning when it's cool, they're tight. I would suggest an electrician and, get someone that's knowledgeable with the codes and, wiring in the area you live in and, the wiring.

- Q:Are aluminum sheets suitable for solar reflectors?

- Certainly, solar reflectors can indeed make use of aluminum sheets. The construction of solar reflectors extensively relies on aluminum owing to its remarkable reflectivity and durability. By virtue of its reflective characteristics, aluminum effectively redirects sunlight onto solar panels or other solar equipment, thereby enhancing energy absorption. Moreover, aluminum is lightweight and resistant to corrosion, making it an excellent choice for outdoor use. Furthermore, its cost-effectiveness and ease of fabrication greatly contribute to its widespread adoption in the solar sector.

- Q:The furnace above is only hot enough to melt lead, but isn't hot enough to melt aluminum. I'm not looking for a blowtorch, or something too expensive or could melt gold, but just something that i can buy and is like the one above but isn't that expensive and can melt aluminum. Thanks!

- Aluminum melts below 1300F These gold and silver melters like the one in the link go to 2000F or more and should work for aluminum. I guess more small melters of metals want to melt gold and silver than aluminum.

- Q:Can the aluminum sheets be used for manufacturing furniture?

- Absolutely, furniture manufacturing can definitely involve the use of aluminum sheets. Due to its lightweight and sturdy nature, aluminum proves to be a perfect choice for crafting furniture that is not only resilient but also conveniently portable. Moreover, its resistance to corrosion ensures endurance even when exposed to different environmental factors. Furthermore, aluminum sheets offer malleability and flexibility, enabling the creation of diverse designs, thus granting furniture manufacturing great versatility. In conclusion, opting for aluminum sheets in furniture manufacturing guarantees the production of top-notch, fashionable, and enduring pieces.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Embossed Aluminum Sheet for Treadplate/ 5052 Aluminium Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords