High Tensile Strength Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

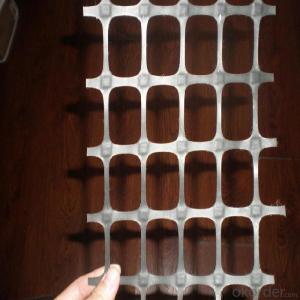

Structure of High Tensile Strength Fiberglass Geogrid Description:

High Tensile Strength Fiberglass Geogrid is a kind of reinforcement product, Both warp and weft directions are high tensile strength and low elongation. It can be used in the construction o railway, highway, bridge, wharf, etc., which require firm-quality construction materials for security purpose. Therefore basalt fiber geogrid is an ideal material for construction.

Main Features of High Tensile Strength Fiberglass Geogrid:

High strength, high modulus and low elongation.

Aging resistance and high tensile strength.

Pre-designed and easily combing with gravel and soil

Could replace steel-plastic geogrid in coal mine.

High Tensile Strength Fiberglass Geogrid Images

High Tensile Strength Fiberglass Geogrid Specification:

Index Properties | Units | MD Values | XMD Values |

Aperture Dimensions | mm(in) | 25(1.0) | 33(1.3) |

Minimun Rib Thickness | mm(in) | 1.27(0.05) | 1.27(0.05) |

Tensile Strength @2% Strain | KN/m(lb/ft) | 6.0(410) | 9.0(620) |

Tensile Strength @5% Strain | KN/m(lb/ft) | 11.8(810) | 19.6(1,340) |

Ultimate Tensile Strength | KN/m(lb/ft) | 19.2(1,310) | 28.8(1,970) |

Junction Efficiency | % | 93 | |

Flexural Stiffness | Mg-cm | 750,000 | |

Aperture Stability | m-N/deg | 0.65 | |

Resistance to Installation Damage | %SC/%SW/%GP | 95/93/90 | |

Resistance to Long Term Degradation | % | 100 | |

Resistance to UV Degradation | % | 100 |

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q1: How about your company?

A1:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q2.Does your products have good qualitity?

A2:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q3:How long can we receive the products after purchase?

A3:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q:What are the two levels of widening of the geogrid in the asphalt concrete road?

- First of all, you must first determine what kind of material you need geogrid, if it is fiberglass geogrid should be placed in the asphalt layer

- Q:Are geogrids suitable for use in reinforced slopes?

- Yes, geogrids are suitable for use in reinforced slopes. Geogrids are highly effective in stabilizing and reinforcing slopes by providing increased tensile strength and distributing loads more evenly. They enhance the stability of the soil, prevent erosion, and can be used in various types of reinforced slope applications, making them a suitable choice for such projects.

- Q:What is the lifespan of geogrids?

- The lifespan of geogrids can vary depending on several factors such as the type of geogrid, installation conditions, and environmental exposure. However, on average, geogrids are designed and manufactured to have a lifespan of around 50 to 100 years, making them a durable and long-lasting solution for soil stabilization and reinforcement.

- Q:Can geogrids be used in coastal protection structures?

- Yes, geogrids can be used in coastal protection structures. Geogrids are commonly used in coastal erosion control measures, such as revetments and seawalls, to reinforce the soil and provide stability. They help improve the overall strength and resistance of the structure to wave forces and erosion, making them an effective solution for coastal protection.

- Q:What is the recommended geogrid junction spacing for specific applications?

- The recommended geogrid junction spacing for specific applications varies depending on factors such as soil conditions, load requirements, and project specifications. It is best to consult with a geotechnical engineer or refer to industry guidelines and standards to determine the appropriate geogrid junction spacing for a specific application.

- Q:How do geogrids improve the performance of soil retaining structures?

- Geogrids improve the performance of soil retaining structures by providing reinforcement and stability to the soil. They distribute the applied loads more evenly, reduce soil movement and prevent the occurrence of sliding or failure. Additionally, geogrids increase the bearing capacity of the soil, enhance drainage, and improve overall durability and longevity of the retaining structures.

- Q:What is the difference between Geogrid and geogrid

- The geotextile is used to prevent seepage and the geogrid is used to reinforceThe geotextile is mainly used for seepage control, isolation, geogrid are generally used in reinforcement reinforcement, the two are essentially different, in the use of the process is sometimes used in the same project, for example, high-speed railway project is made of polypropylene production grid and polyvinyl chloride polymer and thermoplastic or die of two-dimensional grid or a certain height of 3D grid screen,

- Q:Introduction of steel plastic grille

- By a single band,

- Q:Can geogrids be used in railway track stabilization?

- Yes, geogrids can be used in railway track stabilization. Geogrids are commonly used in railway construction and maintenance to reinforce the subgrade and improve load distribution. They help to increase the stability and longevity of the track by reducing settlement and preventing lateral movement of the ballast and subgrade materials.

- Q:Details of fiberglass geogrid

- 1, slow down reflection crackThe reflection crack is due to the old concrete surface layer in the vicinity of the joint or crack of large displacement caused by asphalt overlay in above the stress concentration caused by it, including horizontal displacement caused by changes in temperature and humidity, and caused by the traffic load of the vertical shear displacement. The former leads to the concentrated tensile stress in the asphalt overlay above the joint or crack, while the latter makes the asphalt overlay above the joint undergo large bending stress and shear stress.Because the modulus of geogrid is very large, up to 67Gpa, as the application of hard interlayer stiffness in asphalt overlay layer, its role is to inhibit stress, strain release, and at the same time as the asphalt concrete reinforced material, improve overlay tensile and shear capacity, so as to achieve the purpose of crack reduction. Practice shows that a change in the direction of the horizontal crack corresponding energy can be moved from its starting point 0.6 meters, more than 1.5 meters width of the reinforcement material helps to ensure that the energy dissipated on both sides of the crack completely.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Tensile Strength Fiberglass Geogrid with CE Certificate for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 g/m²

- Supply Capability:

- 600000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords