Polyurethane Foaming Insulation Solar Collector Model SC-HP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Polyurethane Foaming Insulation Solar Collector Model SC-HP:

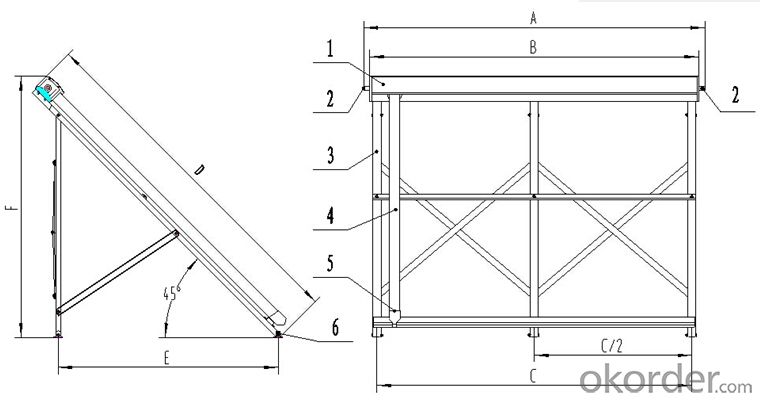

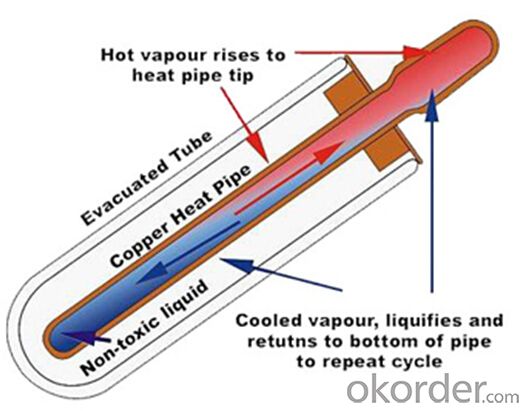

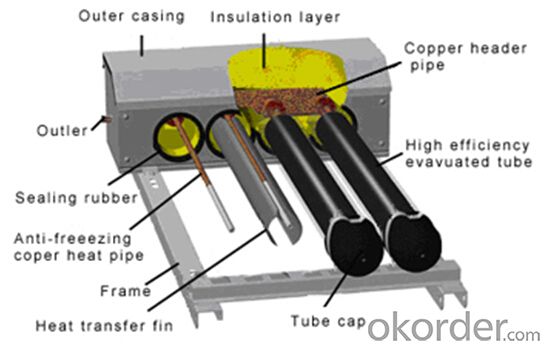

This product is composed of aluminium alloy for frame, polyurethane and aluminium silicate for the insulation,tri-element vacuum glass tube and antifreeze heat pipe. It can work under the environmental temperature from -40℃ to 95℃.The solar collector has the structure as follows:

1,Solar collector manifold :

2,Solar collector connector

3,Solar collector bracket

4,All glass vacuum tube:

5,Tube holder

6,Wind feet

2. Main Features of Polyurethane Foaming Insulation Solar Collector Model SC-HP:

The heat insulation properties is higher than for other types of the same collector design

Three layers of insulation incorporated in the mainfold casing :

(1)first and third layer is Aluminium Silicate and resist temperatures of up to 800℃;

(2)second layer is Polyurethane formed by Italian machine that insulates the tanks with a density of 38.5-42;

3. Polyurethane Foaming Insulation Solar Collector Model SC-HP Images:

4. Polyurethane Foaming Insulation Solar Collector Model SC-HP Specifications

Model | SC-HP-10 | SC-HP-15 | SC-HP-18 | SC-HP-20 | SC-HP-24 | SC-HP-25 | SC-HP-30 |

SC-H1-10 | SC-H1-15 | SC-H1-18 | SC-H1-20 | SC-H1-24 | SC-H1-25 | SC-H1-30 | |

Vacuum tube quantity(pcs) | 10 | 15 | 18 | 20 | 24 | 25 | 30 |

Tube spacing (㎜) | 75 | 75 | 75 | 75 | 75 | 75 | 75 |

Vacuum tube diameter/length (㎜) | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 | φ58/1700 |

Vacuum tube material | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 | high borosilicate glass 3.3 |

Vacuum tube inner/outer pipe wall thickness (㎜) | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 | 1.6/1.8 |

Heat pipe condensing end diameter/length (㎜) | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 | φ14/1750 |

heat pipe material/wall thickness (㎜) | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 | Copper tp2/0.6 |

inner tank diameter/wall thickness (㎜) | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 | φ35/1.0 |

connector size | φ22 or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ | φ22or 3/4″ |

collector insulation material/thickness (㎜) | Polyurethane/40 | Polyurethane/40 | Polyurethane/40 | Polyurethane40 | Polyurethane40 | Polyurethane/40 | Polyurethane/40 |

solar collector rated pressure (MPa) | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

collector operating temperature ℃ | <100 | <100 | <100 | <100 | <100 | <100 | <100 |

collector volume (L) | 0.69 | 0.98 | 1.15 | 1.27 | 1.50 | 1.56 | 1.85 |

collector aperture area (㎡) | 1.0 | 1.5 | 1.8 | 2.0 | 2.4 | 2.5 | 3.0 |

collector total area (㎡) | 1.56 | 2.30 | 2.74 | 3.04 | 3.63 | 3.77 | 4.51 |

referral traffic (L/min) | 0.75 | 1.13 | 1.35 | 1.50 | 1.81 | 1.88 | 2.26 |

intensity pressure (Pa) | 23.2 | 59.2 | 90.6 | 116.7 | 181.7 | 200.2 | 314.0 |

intercept efficient η0 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 | 0.744 |

heat loss coefficient a | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 | 2.09 |

collector power (W)1000W/㎡ irradiation | 620 | 870 | 1047 | 1165 | 1401 | 1457 | 1748 |

collector net weight (kg) | 38.25 | 50.75 | 59.75 | 64.75 | 79.00 | 83.35 | 98.70 |

a (㎜) | 895 | 1270 | 1495 | 1645 | 1945 | 2020 | 1395 |

b (㎜) | 800 | 1175 | 1400 | 1550 | 1850 | 1925 | 2300 |

c (㎜) | 725 | 1100 | 1325 | 1475 | 1775 | 1850 | 2225 |

c/2 (㎜) | —— | —— | —— | —— | 887.5 | 925 | 1112.5 |

d (㎜) | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 | 1980 |

e (㎜) | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 | 1240 |

f (㎜) | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 | 1470 |

5. FAQ

(1) Which collector is the best value for money?

Rather than looking at just peak efficiency levels when comparing solar collectors, cost per unit of energy produced is much more logical. For example: Although collector A may be 20% more efficient than collector B, if collector A is 30% more expensive, then in fact collector B may be a better choice, as per kWh of energy produced per day it is cheaper. When payback time is of concern, not only price per kWh of the product is important, but also of the end system.

(2) Can this solar collectors be used for a large scale hot water production?

Yes. This solar collectors can be connected in series or parallel to provide large scale hot water production for a commercial settings such as a school, hotel or office building. There is really no limit to the size of the system, however collectors must be installed in banks of no more than 150 tubes (in series), otherwise the water may boil.

(3) What maintenance of the solar collector is required?

Under normal circumstances no maintenance of the system is required. Due to the shape of the tubes regular rainfall and wind should keep the tubes clean. Should a tube even be broken it should be replaced. This, however, is an inexpensive and easy job. Any "handy" person can install a new tube (while adhering to local health and safety regulations). Sidite solar collectors can operate with several broken tubes, however the efficiency will be reduced slightly.

- Q:Are there any limitations to the lifespan of solar collectors?

- Yes, there are limitations to the lifespan of solar collectors. These limitations can vary depending on several factors such as the quality of materials used, maintenance practices, and environmental conditions. However, on average, solar collectors can typically last for 20 to 30 years before their efficiency begins to decline. Regular maintenance and proper care can help extend their lifespan.

- Q:Can solar collectors be used in automotive manufacturing?

- Yes, solar collectors can be used in automotive manufacturing. Solar collectors are devices that capture sunlight and convert it into usable energy, typically in the form of heat or electricity. In the context of automotive manufacturing, solar collectors can be used to provide renewable energy for various processes and operations. One potential application of solar collectors in automotive manufacturing is in the generation of electricity. Large photovoltaic arrays can be installed on the roofs or surrounding areas of automotive manufacturing facilities to harness solar energy and convert it into electrical power. This electricity can then be used to power various equipment and machinery in the manufacturing process, reducing reliance on traditional energy sources and lowering carbon emissions. Solar collectors can also be utilized for heating purposes in automotive manufacturing. Solar thermal collectors can capture sunlight and convert it into heat, which can then be used for various heating applications such as space heating, water heating, or even heating specific manufacturing processes. This can help reduce the consumption of fossil fuels or electricity for heating purposes, resulting in cost savings and environmental benefits. Additionally, solar collectors can be integrated into the design of electric vehicles (EVs) themselves. Solar panels can be installed on the roofs or other areas of EVs to capture sunlight and generate electricity, which can then be used to power auxiliary systems within the vehicle. While the electricity generated from these on-board solar collectors may not be sufficient to power the entire vehicle, it can help reduce the energy consumption from the main battery and increase the overall efficiency of the EV. In conclusion, solar collectors can certainly be used in automotive manufacturing. Whether it is through the generation of electricity to power manufacturing processes, heating applications, or even as an integrated component in electric vehicles, solar collectors offer a sustainable and renewable energy solution for the automotive industry.

- Q:Can solar collectors be used in conjunction with other renewable energy sources?

- Yes, solar collectors can be used in conjunction with other renewable energy sources. Many renewable energy systems, such as hybrid solar-wind or solar-hydro, combine solar collectors with other sources to enhance energy production and reliability. This integrated approach allows for a more diverse and sustainable energy mix, maximizing the benefits of multiple renewable sources.

- Q:Can solar collectors be used for heating buildings?

- Yes, solar collectors can be used for heating buildings. Solar thermal collectors can harness the sun's energy to heat water or air, which can then be used to provide heating in buildings. This renewable energy source can be an efficient and sustainable option for heating, reducing reliance on fossil fuels and lowering carbon emissions.

- Q:Are solar collectors suitable for restaurants and cafes?

- Yes, solar collectors are suitable for restaurants and cafes as they can provide a sustainable and cost-effective solution for heating water and generating electricity, reducing energy expenses and carbon footprint. Additionally, they can be installed on rooftops or outdoor spaces, making them adaptable to the limited space often found in urban areas.

- Q:Can solar collectors be used for heating rehabilitation centers?

- Yes, solar collectors can be used for heating rehabilitation centers. Solar thermal systems can efficiently generate heat by collecting and converting sunlight into thermal energy. This renewable energy source can help reduce operating costs and carbon emissions, making it a sustainable option for heating and providing hot water in rehabilitation centers.

- Q:Can solar collectors be used in areas with limited financial resources?

- Yes, solar collectors can be used in areas with limited financial resources. Solar energy is a renewable and abundant resource that can be harnessed and used to generate electricity or heat without relying on expensive fuel sources. Additionally, there are various financing options available, such as government subsidies, grants, and microfinance initiatives, which can help make solar collectors more affordable and accessible to communities with limited financial resources.

- Q:Can solar collectors be used for generating steam?

- Yes, solar collectors can be used for generating steam. Solar thermal collectors, such as parabolic troughs or solar towers, can concentrate sunlight to heat water or other fluids, producing steam that can be used for various industrial processes or to generate electricity in steam turbines. This process is known as solar thermal power generation.

- Q:Can solar collectors be used in advocacy for renewable energy?

- Yes, solar collectors can definitely be used in advocacy for renewable energy. Solar collectors, also known as solar panels or solar photovoltaic (PV) systems, are a prime example of harnessing solar energy to generate electricity. By showcasing the effectiveness and benefits of solar collectors, advocates can highlight the potential of renewable energy sources like solar power. This helps raise awareness about the importance of transitioning to clean and sustainable energy alternatives, ultimately contributing to the overall promotion and adoption of renewable energy.

- Q:Can solar collectors be used for radiant floor heating?

- Yes, solar collectors can be used for radiant floor heating. Solar collectors, such as solar thermal panels or evacuated tube collectors, can capture solar energy and transfer it to a fluid which can then be used to heat the floors through a radiant system. This method is an efficient and sustainable way to provide warmth to a building's floors using renewable energy sources.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyurethane Foaming Insulation Solar Collector Model SC-HP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 set

- Supply Capability:

- 200 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords