HDPE Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction:

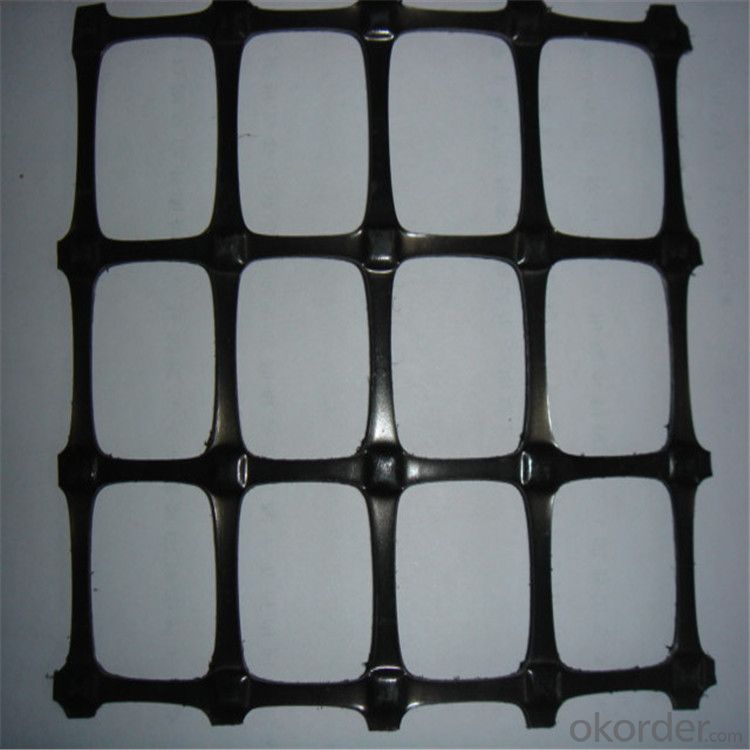

HDPE Uniaxial geogrid, made of high molecular polymer, is extruded into sheet and then punched

into regular mesh pattern, and finally stretched in the longitudinal direction.

Application:

Mainly applied in highway, railway, slope protecting projects, retaining wall, dam etc.

1) strengthen land loading capacity

and extend its service life.

2) convenient to construct ;

reducing area , project cost and maintenance cost.

Tensile Strength ≧(Kn/m) | MD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | |

TD | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | ||

Nominal Elongation ≦(%) | MD | 15 | ||||||||

TD | 13 | |||||||||

Tensile Strength at 2% Strain ≧(Kn/m) | MD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | |

TD | 5 | 7 | 9 | 10.5 | 12 | 14 | 16 | 17.5 | ||

Tensile Strength at 5% Strain ≧(Kn/m) | MD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | |

TD | 7 | 14 | 17 | 21 | 24 | 28 | 32 | 35 | ||

Junction Efficiency (%) | 93 | |||||||||

Width ≦(m) | 6 | |||||||||

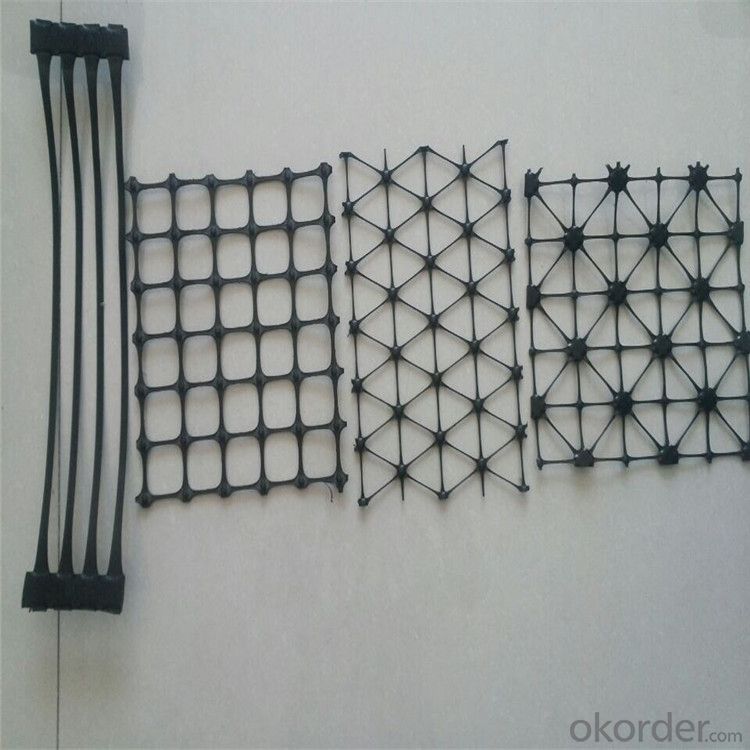

Images of HDPE Biaxial Geogrid

- Q:Can geogrids be used in reinforcement of embankments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of embankments on collapsible soils. Geogrids provide additional stability and strength to the embankment, helping to prevent soil collapse and reduce potential settlement. By distributing loads more evenly, geogrids can effectively reinforce the embankment and improve its overall performance on collapsible soils.

- Q:How are geogrids installed in the field?

- Geogrids are typically installed in the field by first preparing the subgrade by removing any vegetation or loose soil. The geogrid is then rolled out and placed on top of the subgrade, ensuring it is properly aligned and covers the desired area. It is then secured in place using stakes, pins, or other anchoring methods. Finally, the geogrid is covered with a layer of fill material, such as soil or gravel, which is compacted to provide additional stability and load-bearing capacity.

- Q:Do geogrids enhance the load-bearing capacity of soil?

- Yes, geogrids enhance the load-bearing capacity of soil.

- Q:How do geogrids enhance the performance of geosynthetic clay liner erosion control blankets?

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability to the clay liner. They help distribute the loads more evenly, reduce soil movement, and prevent erosion by reinforcing the liner's tensile strength. This enhances the overall effectiveness and longevity of the erosion control system.

- Q:Are geogrids suitable for use in mining tailings dams?

- Yes, geogrids are suitable for use in mining tailings dams. Geogrids are engineered materials that provide reinforcement and stability to the soil, making them an ideal solution for constructing and reinforcing tailings dams in mining operations. They improve the strength and load-bearing capacity of the dams, prevent soil erosion, and enhance the overall stability and safety of the structure.

- Q:What are the maintenance requirements for geogrid-reinforced structures?

- The maintenance requirements for geogrid-reinforced structures typically involve periodic inspections to ensure the stability and integrity of the structure. This may include checking for any signs of soil erosion, settlement, or damage to the geogrid material. Regular maintenance activities may also involve removing any vegetation or debris that could potentially undermine the structure. Additionally, routine monitoring of the structure's performance and conducting necessary repairs or reinforcements as needed is essential to ensure its long-term stability and functionality.

- Q:What is the effect of junction strength on geogrid performance?

- The effect of junction strength on geogrid performance is significant. A stronger junction ensures better interlocking and connection between the geogrid's components, leading to enhanced load distribution and resistance against installation stress and long-term deformation. It allows the geogrid to effectively restrain and stabilize the soil, improving overall geotechnical performance and longevity.

- Q:How do geogrids prevent soil erosion?

- Geogrids prevent soil erosion by providing stability and reinforcement to the soil. They are typically made of high-strength materials, such as polyester or polypropylene, and are installed within the soil to distribute and transfer loads. This helps to increase the soil's resistance to erosion caused by factors like water flow or slope instability. The geogrids act as a barrier that holds the soil particles together, preventing them from being washed away or displaced.

- Q:How do geogrids improve the performance of unpaved parking lots?

- Geogrids improve the performance of unpaved parking lots by providing reinforcement and stabilization to the soil, preventing its movement and reducing the amount of settlement and rutting. This helps to distribute the load evenly and increase the overall strength and durability of the parking lot, ensuring it can withstand heavy traffic and adverse weather conditions.

- Q:Are geogrids suitable for reinforcing landfill caps?

- Yes, geogrids are suitable for reinforcing landfill caps. Geogrids are commonly used in landfill engineering to enhance the stability and strength of landfill caps. They provide reinforcement and prevent the movement and erosion of soil, thereby increasing the overall efficiency and effectiveness of landfill caps in containing waste materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

HDPE Geogrid with High Tensile Strength Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 g/m²

- Supply Capability:

- 100000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords