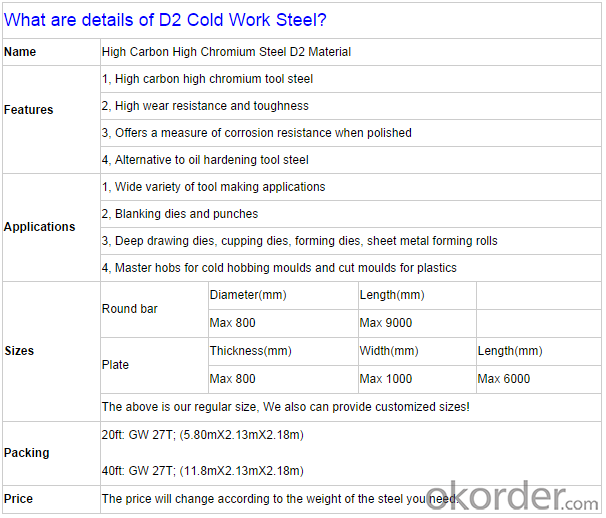

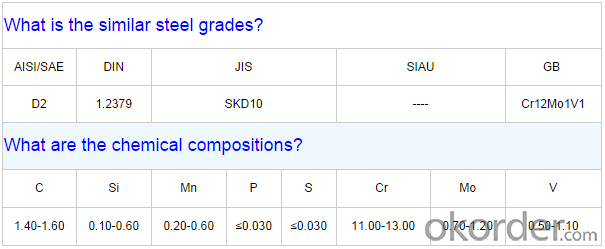

High Carbon High Chromium Steel D2 Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Item specifice

Type:

Carbon Steel

Shape:

Steel Round Bar

High Carbon High Chromium Steel D2 Material

Product information:

Specifications

High Carbon High Chromium Steel D2 Material

1.Various Specification

2.On Time Delivery

3.Sample: Free

4.24hrs online

Product show

Workshop show

Our service:

- Q:What are the different types of heat-resistant steel?

- There are various types of heat-resistant steel, including austenitic stainless steels, martensitic stainless steels, ferritic stainless steels, and precipitation hardening stainless steels. Additionally, nickel-based alloys such as Inconel and Hastelloy, as well as refractory metals like tungsten and molybdenum, are also considered heat-resistant steel materials.

- Q:How does special steel contribute to improving product durability?

- Special steel contributes to improving product durability in several ways. Firstly, special steel has superior strength and toughness compared to regular steel, making it more resistant to wear and tear. This allows products made from special steel to withstand heavy usage and harsh conditions without losing their structural integrity. Additionally, special steel is often more corrosion-resistant, preventing rust and other forms of deterioration that can compromise a product's longevity. Lastly, special steel can be tailored to specific applications, enabling manufacturers to design products with optimal performance and durability in mind. Overall, special steel plays a crucial role in enhancing product durability and extending their lifespan.

- Q:How does special steel perform in high-frequency applications?

- Special steel performs well in high-frequency applications due to its excellent conductivity and high magnetic permeability. These properties allow it to efficiently transmit and handle high-frequency currents and electromagnetic fields, minimizing energy losses and ensuring efficient performance in applications such as transformers, electrical motors, and high-frequency electromagnetic shielding.

- Q:How does special steel contribute to the oil and gas aftermarket industry?

- Due to its unique properties and capabilities, special steel plays a vital role in the oil and gas aftermarket industry. Its resistance to corrosion makes it well-suited for use in the harsh and corrosive environments commonly found in this sector. By preventing corrosion, special steel extends the lifespan of equipment and components, reducing the need for frequent replacements and maintenance. Additionally, special steel offers high strength and durability, enabling it to withstand the extreme pressures and temperatures encountered in oil and gas operations. This strength ensures that equipment and components made from special steel can function reliably and efficiently, even under demanding conditions. Moreover, special steel can be customized to meet the specific requirements of the oil and gas industry. With its various grades and compositions, special steel can possess specific properties, such as resistance to sulfide stress cracking, hydrogen embrittlement, and high-temperature oxidation. These tailored properties make special steel suitable for critical applications, including wellheads, pipelines, valves, and other equipment used in the oil and gas aftermarket industry. Furthermore, special steel allows for the production of complex and intricate components that are essential for the oil and gas sector. Its excellent machinability and weldability enable the creation of precision-engineered parts, ensuring the efficient and reliable operation of oil and gas equipment. In conclusion, special steel plays a significant role in the oil and gas aftermarket industry by providing corrosion resistance, high strength, durability, customization options, and the ability to manufacture intricate components. These properties make special steel indispensable in ensuring the safety, reliability, and efficiency of operations in the oil and gas sector.

- Q:What are the different types of wear-resistant steel?

- There are several different types of wear-resistant steel, including AR400, AR500, HARDOX, and DOMEX. These types of steel are specifically designed to withstand abrasive wear and impact, making them ideal for applications such as mining equipment, excavator buckets, and conveyor systems. They have high hardness and toughness properties, which help to prolong the lifespan of the equipment and reduce maintenance costs.

- Q:What are the different stamping grades of special steel?

- The different stamping grades of special steel include stainless steel, high-strength steel, tool steel, and alloy steel. Each grade has unique properties and characteristics that make them suitable for various stamping applications.

- Q:How does special steel contribute to the manufacturing of structural components?

- Special steel plays a crucial role in the manufacturing of structural components due to its unique properties and characteristics. Firstly, special steel offers exceptional strength and durability, making it an ideal material for constructing load-bearing structures. It can withstand high levels of stress, pressure, and heavy loads, ensuring the structural integrity and safety of the components. Furthermore, special steel possesses excellent corrosion resistance, which is particularly important for structural components exposed to harsh environments, such as bridges, offshore platforms, or buildings near the coast. This corrosion resistance helps prevent rusting and deterioration, prolonging the lifespan of the structural components and reducing maintenance costs. Moreover, special steel offers a high degree of versatility in terms of design and fabrication. It can be easily shaped, molded, and welded, allowing manufacturers to create complex and intricate structural components with precision. This flexibility enables the production of customized components that meet specific requirements and specifications, enhancing the overall performance and functionality of the structures. Additionally, special steel exhibits excellent heat resistance and fireproofing properties, making it suitable for components exposed to high temperatures or fire hazards. This is particularly important in the manufacturing of structural components for industrial facilities, power plants, or transportation infrastructure, where fire protection is vital. Furthermore, special steel often has superior fatigue resistance, enabling it to withstand repetitive or cyclic loading without suffering from fatigue failure. This property is crucial for structural components subjected to dynamic or fluctuating loads, such as bridges, cranes, or machinery parts. Overall, special steel greatly contributes to the manufacturing of structural components by providing strength, durability, corrosion resistance, versatility in design, heat resistance, fireproofing, and fatigue resistance. Its unique properties make it an essential material choice for constructing safe, reliable, and long-lasting structures across various industries.

- Q:How does special steel contribute to the energy generation industry?

- Special steel plays a crucial role in the energy generation industry by contributing to the efficiency, reliability, and safety of various components and equipment used in power plants. One key area where special steel is essential is in the construction of turbine blades and generator rotors. These components are subjected to extreme temperatures, pressures, and mechanical stresses. Special steels, such as superalloys, are specifically designed to withstand these harsh conditions, ensuring the longevity and performance of these critical parts. By using special steel, power plants can operate at higher temperatures and pressures, leading to increased energy efficiency and power output. In addition to turbine components, special steel is also used in the construction of boilers and heat exchangers. These components are exposed to high temperatures and corrosive environments. Special steel alloys, such as stainless steels, are highly resistant to corrosion and can withstand the harsh conditions encountered in power plant operations. This corrosion resistance ensures the longevity and reliability of these components, reducing maintenance costs and downtime. Furthermore, special steel is utilized in the construction of transmission and distribution infrastructure. Steel cables and conductors are used to transmit electricity over long distances, and special steel alloys provide the necessary strength and conductivity for efficient power transmission. Additionally, steel is used in the construction of towers, poles, and other support structures, ensuring the stability and reliability of the electrical grid. Moreover, special steel is also vital in the production of nuclear energy. Nuclear power plants require materials that can withstand extreme temperatures, high radiation levels, and corrosive environments. Special steel alloys, such as stainless steels and nickel-based alloys, are specifically designed to meet these requirements, providing the necessary strength, resistance to radiation, and corrosion resistance for the safe and efficient operation of nuclear reactors. In summary, special steel is an integral part of the energy generation industry. Its unique properties and capabilities contribute to the efficiency, reliability, and safety of various components and equipment used in power plants. By using special steel, power plants can increase energy efficiency, reduce maintenance costs, and ensure the longevity and performance of critical infrastructure, ultimately supporting the sustainable and reliable generation of electricity.

- Q:Can special steel be used for musical instruments?

- Yes, special steel can be used for musical instruments. In fact, many high-quality instruments such as saxophones, trumpets, and guitars are made using different types of steel. Special steel alloys like stainless steel or nickel silver offer unique tonal qualities and durability, making them suitable for producing musical instruments with excellent sound projection and longevity.

- Q:What are the main characteristics of alloy steel?

- Alloy steel, which is produced by incorporating specific elements like chromium, nickel, or molybdenum into iron, possesses distinct properties and qualities. Some key features of alloy steel are as follows: 1. Remarkable strength: Alloy steel is renowned for its exceptional strength. The introduction of alloying elements enhances its capacity to endure high pressures and heavy loads, making it an ideal choice for applications necessitating a robust and long-lasting material. 2. Enhanced hardness: Alloy steel is also recognized for its hardness, surpassing that of regular carbon steel. This attribute renders it resistant to wear, abrasion, and deformation, making it suitable for applications that require resistance to impact or wear, such as the production of cutting tools or machinery components. 3. Resistance to corrosion: Depending on the specific alloying elements employed, alloy steel can display excellent resistance to corrosion. For instance, the addition of chromium is a common practice to create stainless steel, which exhibits high resistance to rust and corrosion. This attribute positions alloy steel as a preferred material in industries where exposure to moisture or corrosive environments is prevalent. 4. Heat endurance: Alloy steel possesses the ability to withstand high temperatures without compromising its strength or structural integrity. The inclusion of elements like nickel, molybdenum, or vanadium augments its resistance to thermal expansion, oxidation, and softening at elevated temperatures. This quality renders alloy steel suitable for applications in the aerospace, automotive, and power generation sectors. 5. Versatility: Alloy steel is a versatile material that can be readily tailored to meet specific requirements. Manufacturers can create alloy steel with a broad range of properties, such as improved ductility, toughness, or electrical conductivity, by modifying the composition and proportions of alloying elements. This adaptability permits the utilization of alloy steel in diverse industries, encompassing construction, manufacturing, and engineering. In conclusion, alloy steel exhibits high strength, hardness, corrosion resistance, heat endurance, and versatility. These characteristics establish alloy steel as the preferred choice for a wide array of applications that demand a sturdy, durable, and dependable material.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Carbon High Chromium Steel D2 Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Related keywords