CNBM hot sell 304,202 stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

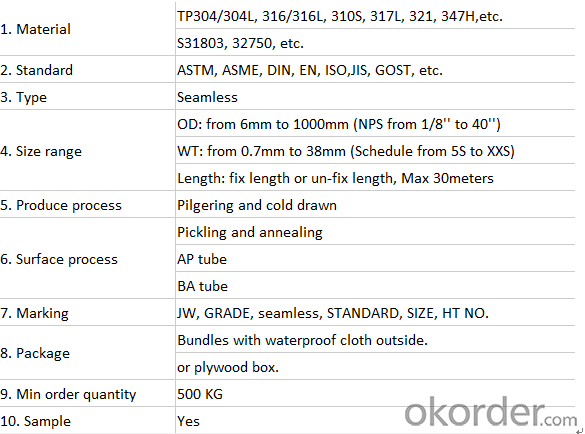

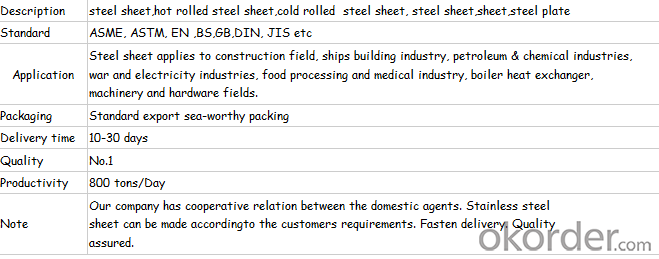

1,the desciption of the hot sell stainless steel pipe

2,the application of the hot sell stainelss steel 304 201 stainless steel pipe

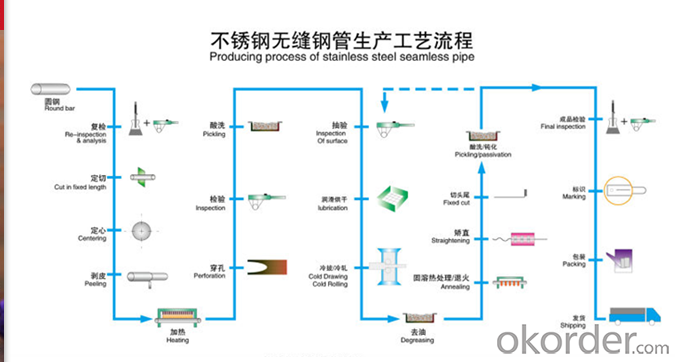

3,the producing procedure

4,related products show

5,FAQ

Q: WHAT ARE YOUR ADVANTAGES?

A: 1. We have a specialized team in dealing with all the documents required by customers. We aim to zero error to save money and time for client. 2. We have a strict quality control from production to delivery. 3. We take use of advanced system and tool to improve working efficiency and control every step. 4. Professional sales team to serve customers. 5. Samples can be provided as your requirements. 6. Professional packing team which keep every packing safely.

Q: WHAT ARE YOUR MAIN PRODUCT?

A: We are specializing in providing cold rolled 201/410/430 Stainless Steel Coil / Stainless Steel Strip / Stainless Steel Sheet / Stainless Steel Plate, Stainless Steel Circle, Stainless Steel tube / Stainless Steel Pipe Sheets.

Q: CAN I GET FREE SAMPLE?

A: YES. We can provide free sample. However, you should be responsible for the transportation freight. Please tell us your express account or please send us the transportation freight of samples firstly, then we can arrange sample delivery.

Q: HOW MUCH THE TRANSPORTATION FREIGHT WILL BE FOR THE SAMPLES?

A: The freight depends on the weight and packing size and your area.

- Q:What is the maximum temperature stainless steel pipes can withstand?

- The maximum temperature that stainless steel pipes can withstand depends on the specific grade of stainless steel used. Generally, stainless steel pipes can withstand high temperatures ranging from 1200°C to 1400°C (2200°F to 2550°F). However, it is important to note that the exact maximum temperature may vary based on factors such as the composition of the stainless steel, the duration of exposure to high temperatures, and the presence of any corrosive elements in the environment. It is always recommended to consult the manufacturer's specifications or a professional engineer for specific temperature limits for a particular grade of stainless steel pipe.

- Q:What is the difference between 2205 and 2507 stainless steel pipes?

- The chemical composition and corrosion resistance properties differentiate 2205 stainless steel pipes from 2507 stainless steel pipes. 2205 stainless steel is a duplex stainless steel that consists of a balanced proportion of austenite and ferrite phases. It contains approximately 22% chromium, 5% nickel, 3% molybdenum, and small amounts of nitrogen and other elements. This composition provides 2205 stainless steel with good strength, excellent corrosion resistance, and high resistance to stress corrosion cracking. On the contrary, 2507 stainless steel is a super duplex stainless steel with higher levels of chromium, nickel, molybdenum, and nitrogen compared to 2205. It typically comprises around 25% chromium, 7% nickel, 4% molybdenum, and 0.25% nitrogen, along with other alloying elements. These additions improve the corrosion resistance, strength, and overall performance of 2507 stainless steel pipes, especially in highly corrosive environments like seawater, chemicals, and acidic solutions. In terms of corrosion resistance, 2507 stainless steel pipes exhibit superior resistance to pitting, crevice corrosion, and general corrosion in comparison to 2205 stainless steel. Consequently, 2507 stainless steel pipes are highly suitable for applications requiring extreme corrosion resistance, such as offshore oil and gas platforms, chemical processing plants, and desalination plants. In summary, although both 2205 and 2507 stainless steel pipes belong to the duplex stainless steel category, the higher alloy content and enhanced corrosion resistance of 2507 stainless steel pipes make them more suitable for severe and corrosive environments. Nonetheless, 2205 stainless steel pipes still offer excellent performance and can be a cost-effective alternative for less demanding applications.

- Q:What is the chemical composition of stainless steel pipes?

- Stainless steel pipes are primarily composed of iron, chromium, and varying amounts of other elements depending on the specific grade or type of stainless steel. The main component is iron, which provides the structural strength and durability. Chromium is the key element that gives stainless steel its corrosion-resistant properties. It forms a thin, passive layer on the surface of the steel, protecting it from oxidation and rust. Other elements commonly found in stainless steel pipes include nickel, molybdenum, and manganese, which further enhance its corrosion resistance, strength, and other specific properties. The specific chemical composition of stainless steel pipes can vary widely depending on the grade and intended application, allowing for different levels of strength, corrosion resistance, and heat resistance.

- Q:Can stainless steel pipes be anodized?

- No, stainless steel pipes cannot be anodized. Anodizing is a process that is typically used on aluminum to create a protective oxide layer on its surface. Stainless steel already has a natural oxide layer, known as a passive layer, which forms spontaneously when exposed to oxygen. This passive layer provides corrosion resistance to stainless steel pipes and does not require anodizing. Therefore, anodizing is not necessary or feasible for stainless steel pipes.

- Q:What are the different types of stainless steel pipe nipples?

- There are several different types of stainless steel pipe nipples, including threaded, seamless, welded, and close nipple.

- Q:Can stainless steel pipes be used in the construction industry?

- Indeed, the utilization of stainless steel pipes in the construction industry is feasible. Stainless steel presents numerous advantages, establishing it as a preferred option for diverse construction applications. Initially, the outstanding corrosion resistance of stainless steel pipes is indispensable in construction ventures involving exposure to moisture, chemicals, or severe weather conditions. This resistance against corrosion guarantees the pipes' longevity and durability, subsequently reducing costs associated with maintenance and replacement. Moreover, stainless steel pipes possess remarkable strength and impact resistance, rendering them appropriate for structural purposes in buildings, bridges, and other construction projects. Their strength facilitates the transportation of fluids and gases under high pressure, thus making them ideal for plumbing and HVAC systems. Furthermore, stainless steel pipes demonstrate a high level of hygienic properties and resistance to bacteria growth, which renders them appropriate for implementation in the food and beverage industry, hospitals, and laboratories. These pipes are easily maintained and cleaned, ensuring the safety and purity of the transported materials. Additionally, stainless steel pipes have an aesthetic appeal, as they can be polished to a high shine or finished in various colors, thereby making them suitable for architectural usage. They can be employed for handrails, staircases, exterior cladding, and other decorative components in buildings. In summary, stainless steel pipes are versatile, durable, and corrosion-resistant, which ultimately establishes them as an exceptional choice for the construction industry.

- Q:Can stainless steel pipes be surface treated?

- Yes, stainless steel pipes can be surface treated through various methods such as pickling, passivation, electropolishing, or coating to enhance their appearance, corrosion resistance, and durability.

- Q:Can stainless steel pipes be insulated with polyamide?

- Yes, stainless steel pipes can be insulated with polyamide. Polyamide is a commonly used material for pipe insulation due to its excellent thermal properties and resistance to high temperatures. It provides effective insulation and helps to prevent heat loss or gain in the pipes.

- Q:What is the difference between 304F and 316F stainless steel pipes?

- The composition and characteristics of 304F and 316F stainless steel pipes are what set them apart. 304F stainless steel is categorized as an austenitic stainless steel, meaning it contains high levels of chromium and nickel. It is renowned for its exceptional corrosion resistance, weldability, and formability. Consequently, it is widely used in various industries, including food processing, chemical processing, and construction. However, 304F stainless steel is not as resistant to chloride corrosion as 316F stainless steel. On the flip side, 316F stainless steel is also classified as an austenitic stainless steel, but it has elevated levels of chromium, nickel, and molybdenum compared to 304F stainless steel. The addition of molybdenum enhances its corrosion resistance, particularly against chlorides and other aggressive chemicals. As a result, 316F stainless steel pipes are suitable for more demanding applications, such as marine environments, where exposure to saltwater and corrosive chemicals is prevalent. To sum up, the key difference between 304F and 316F stainless steel pipes lies in their corrosion resistance. While both are classified as austenitic stainless steels, 316F stainless steel offers superior resistance to chloride corrosion, making it the superior choice for applications where corrosion resistance is of utmost importance.

- Q:What is the difference between sanitary and industrial stainless steel pipes?

- The main difference between sanitary and industrial stainless steel pipes lies in their intended use and the level of cleanliness required. Sanitary stainless steel pipes are specifically designed for use in industries such as food, beverage, pharmaceuticals, and biotechnology, where maintaining high levels of cleanliness and hygiene is crucial. These pipes are polished to a smooth, easy-to-clean finish, and often have special features like removable fittings to prevent contamination. On the other hand, industrial stainless steel pipes are used in a wide range of applications, including oil and gas, chemical processing, and power generation. While they are still made of stainless steel, they may not have the same level of surface finish and sanitation requirements as sanitary pipes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CNBM hot sell 304,202 stainless steel pipe

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords