Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

Product information

1. Produce Standard: GB, AISI, ASTM, SAE, EN, BS, DIN, JIS

2. Produce processes: Smelt Iron -EAF smelt Billet - ESR smelt Billet -Hot rolled or forged get the steel round bar and plate

3. Heat treatment: Normalized / Annealed / Quenched+Tempered

4. Quality assurance: All order we can received third party inspection, You can let SGS, BV,.. and others test company test and inspect our products before Goods shipping.

Product detail

| Material | 40Mn 50Mn 20CrNi4 | Round bar | Dia(mm) | 16-600 |

| Process | EAF + LF + VD + Forged + Heat Treatment (optional) | Length (mm) | Max 12000 | |

| Heat treatment | Normalized / Annealed / Quenched / tempered | Flat bar | Thickness(mm) | 8-500 |

| Delivery condition | Hot forged +Rough machined (black surface after Q/T)+ Turned (optional) | Width(mm) | 70-200 | |

| Test | Ultrasonic test according to SEP 1921-84 D/d | Length (mm) | Max 12000 | |

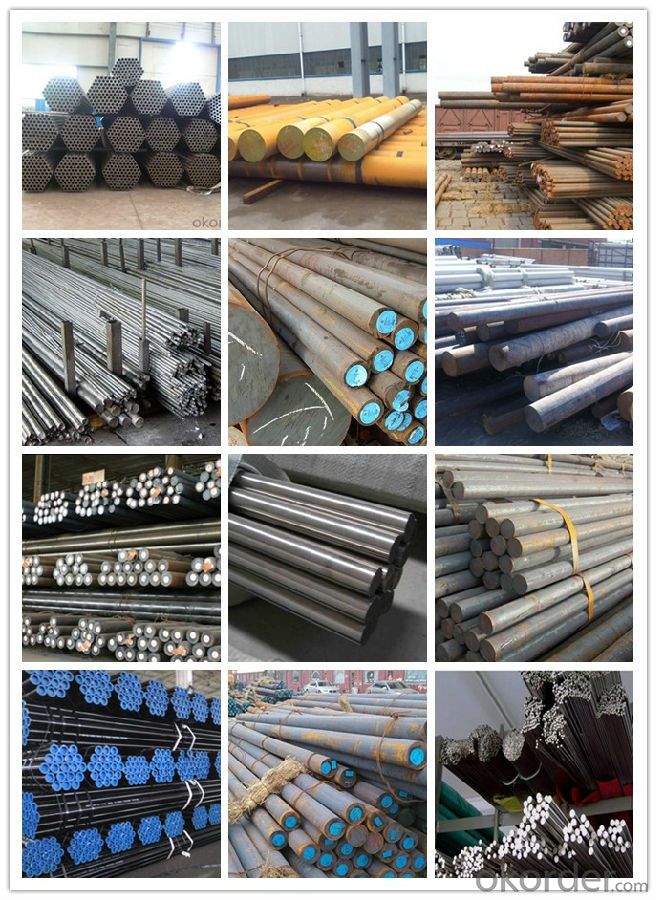

Product show

Work shop

Our Services

* Welcome to contact us with your detailed inquiry, you will be replied within 24 hours.

* You are promised to obtain the best quality, price and service.

* We'd like to provide samples for your confirm.

- Q:How does special steel perform in electrical conductivity applications?

- Special steel, due to its high electrical conductivity, performs exceptionally well in electrical conductivity applications. Its low resistance allows for efficient flow of electrical currents, making it ideal for various electrical and electronic components such as wiring, connectors, and conductors. Additionally, special steel's corrosion resistance properties ensure long-term performance and durability in demanding electrical environments.

- Q:How does special steel perform in marine environments?

- Special steel is specifically designed to withstand the harsh conditions of marine environments. It offers superior corrosion resistance, high strength, and excellent durability, making it highly suitable for applications in marine settings. This type of steel can effectively resist the corrosive effects of saltwater, moisture, and other environmental factors, ensuring long-term performance and reducing maintenance requirements.

- Q:What are the different types of heat treatment processes used for special steel?

- There are several types of heat treatment processes used for special steel, including annealing, normalizing, quenching, tempering, and case hardening. These processes are used to modify the properties of the steel, such as improving its hardness, strength, and toughness, to meet specific application requirements.

- Q:Can special steel be used in the energy sector?

- Yes, special steel can be used in the energy sector. Special steel refers to various types of high-performance alloys that are specifically designed for applications that require exceptional strength, durability, and resistance to corrosion and extreme temperatures. These properties make special steel an ideal choice for numerous components used in the energy sector. In the oil and gas industry, special steel is commonly used for the construction of pipelines, drilling equipment, and offshore platforms. Its high strength and corrosion resistance help in ensuring the integrity and reliability of these critical structures, even in harsh environments. Special steel is also widely utilized in power generation plants. For example, in thermal power plants, where steam is generated to produce electricity, special steel is used to manufacture boiler tubes and pressure vessels. The exceptional heat resistance and structural integrity of special steel ensure the safe and efficient operation of these components under high temperatures and pressure. Furthermore, special steel finds applications in renewable energy sectors such as wind and solar power. In wind turbines, for instance, special steel is used to manufacture rotor shafts, gears, and bearings, which are subjected to high mechanical loads. Similarly, in concentrated solar power plants, special steel is employed in the construction of the heat exchangers, receivers, and storage systems. Overall, the use of special steel in the energy sector is crucial for enhancing the overall performance, safety, and longevity of various components and structures. Its unique properties make it an indispensable material in supporting the energy industry's infrastructure and operations.

- Q:Can special steel be used in the manufacturing of firearms?

- Special steel is unquestionably applicable for firearm production. In truth, it is frequently favored for this purpose owing to its distinct properties that render it apt for enduring high temperatures, pressures, and stress. Firearms necessitate materials that possess strength, durability, and the capability to withstand the immense forces generated during firing. Special steel alloys, such as stainless steel or heat-treated steel, provide these desired traits and are extensively employed in fabricating firearm barrels, receivers, and other crucial constituents. The incorporation of special steel in firearm manufacturing guarantees the dependability, safety, and consistent performance of these weapons in diverse conditions.

- Q:How does special steel contribute to the industrial equipment industry?

- Special steel plays a crucial role in the industrial equipment industry by providing superior strength, durability, and resistance to various harsh conditions. Special steel alloys are specifically engineered to possess exceptional properties that make them suitable for a wide range of applications in industrial equipment. One of the key contributions of special steel to the industry is its ability to withstand high temperatures and pressure. This makes it an ideal material for manufacturing components such as boilers, turbines, and heat exchangers. Special steel's high heat resistance ensures that these equipment can operate efficiently and reliably in demanding environments, thereby enhancing overall performance and safety. Furthermore, special steel is renowned for its excellent corrosion resistance, making it highly suitable for manufacturing equipment that comes into contact with corrosive substances. This includes chemical processing equipment, oil and gas pipelines, and marine structures. By using special steel in these applications, the industrial equipment industry can ensure longer operational lifetimes, reduce maintenance costs, and minimize the risk of catastrophic failures. Special steel also contributes to the industry by enabling the production of equipment with superior mechanical properties. Its unique composition and heat treatment processes allow for increased strength, toughness, and wear resistance. As a result, industrial equipment made from special steel can handle heavy loads, endure extreme conditions, and provide long-lasting performance. Additionally, special steel alloys can be tailored to meet specific requirements, allowing for the production of custom-made components. This flexibility enables the industrial equipment industry to design and manufacture equipment that meets the exact needs of various sectors, including aerospace, automotive, energy, and construction. Special steel's versatility and adaptability thus play a vital role in driving innovation and technological advancements within the industry. In conclusion, special steel significantly contributes to the industrial equipment industry by providing exceptional strength, durability, resistance to harsh conditions, and customized solutions. Its unique properties make it an essential material for manufacturing a wide range of equipment, ultimately enhancing performance, reliability, and safety across various sectors.

- Q:Can special steel be used in the production of turbine blades?

- Yes, special steel can be used in the production of turbine blades. Special steel, such as superalloys, offers excellent high-temperature strength, corrosion resistance, and fatigue resistance, making it ideal for turbine blade applications where these properties are crucial for optimal performance and durability.

- Q:What are the requirements for special steel used in packaging machinery?

- The requirements for special steel used in packaging machinery include high strength and durability, resistance to corrosion and wear, excellent heat resistance, and the ability to be easily machined and processed. Additionally, the steel should have good dimensional stability, be able to withstand high pressures and impacts, and have low friction properties.

- Q:What are the properties of corrosion-resistant stainless steel?

- Corrosion-resistant stainless steel possesses several key properties that make it highly resistant to corrosion. These properties include a high chromium content, which forms a protective oxide layer on the surface of the steel, preventing corrosion. Additionally, stainless steel is often alloyed with other elements such as nickel and molybdenum, which further enhance its corrosion resistance. The steel is also highly durable, with excellent strength and toughness, making it suitable for a wide range of applications in various industries. Overall, corrosion-resistant stainless steel offers exceptional resistance to corrosion, ensuring its longevity and reliability in harsh environments.

- Q:What are the applications of special steel in the agriculture sector?

- Special steel has numerous applications in the agriculture sector. It is used in the manufacturing of machinery and equipment such as plows, cultivators, and harvesters, due to its high strength and durability. Special steel is also utilized in the production of storage tanks and silos, providing protection against corrosion and ensuring the safety of agricultural products. Additionally, it is employed in the fabrication of irrigation systems, fencing, and animal enclosures, offering longevity and resistance to wear and tear. Overall, special steel plays a crucial role in improving productivity and efficiency in various agricultural operations.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Alloy Round Steel Bar 40Mn 50Mn 20CrNi4

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords