High Quality and Stainless Alloyed Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering High Quality and Stainless Alloyed Flat Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality and Stainless Alloyed Flat Bar are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality and Stainless Alloyed Flat Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications for Stainless Alloyed Flat Bar

the wire rod steel for construction that we offer have been used in civil construction work for years.

SPECIFICATION

1: WIRE ROD IN COIL

2. STANDARD: AISI,ASTM,BS,DIN,GB,JIS

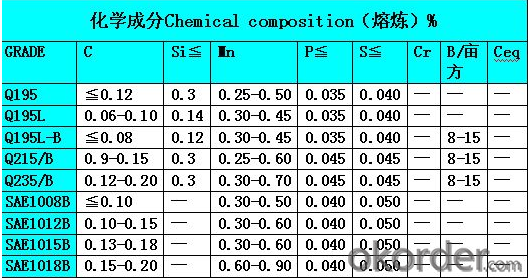

3. STEEL GRAD: Q195--235/SAE1006B/SAE1008B/SA31012B/SDA31015B/SA31018B/SA31022B

4. SIZE: 5--22MM

1) the products that we offer haven been used in civil constrction work for years

2) meet different requirment

3) we can offer accordingly with different demands

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: What makes stainless steel stainless?

A2: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3: Can stainless steel rust?

A3: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q:Can steel flat bars be used for making gardening tools?

- Yes, steel flat bars can be used for making gardening tools. Steel is a durable and strong material that is commonly used in the manufacturing of various tools, including gardening tools. Steel flat bars can be easily shaped and formed into different types of gardening tools such as shovels, hoes, rakes, and trowels. They provide the necessary strength and stability required for these tools to perform their intended functions effectively. Additionally, steel is resistant to rust and corrosion, making it suitable for outdoor use in gardening applications, where tools are often exposed to moisture and other environmental elements. Overall, steel flat bars are a versatile and reliable material choice for making gardening tools.

- Q:How do you join two steel flat bars together?

- One way to join two steel flat bars together is by using a welding technique such as arc welding or MIG welding. This involves heating the bars and melting a filler material to create a strong bond between the two bars. Another option is to use mechanical fasteners like bolts, screws, or rivets to secure the bars together. Additionally, adhesive bonding can be considered using high-strength industrial adhesives designed for metal bonding. The choice of the method depends on the specific requirements of the project and the available resources.

- Q:Cold rolled flat steel standard. What is cold rolled flat steel?

- Section steel is one of the four major steel products (plate, tube, mould, wire). According to the section shape, the section steel is divided into simple section steel and complex section steel (deformed steel). The former refers to the steel, round steel, flat steel, angle steel, six angle steel; the latter refers to the I-beam, channel steel, steel, steel, steel frame bending etc..

- Q:How do steel flat bars perform under fatigue loading conditions?

- Due to their high strength and durability, steel flat bars exhibit excellent performance under fatigue loading conditions. Fatigue loading occurs when cyclic loads are repeatedly applied to a material, which can lead to the formation of cracks and eventual failure over time. Steel flat bars are specifically designed to endure such loading conditions by possessing outstanding fatigue resistance. This is primarily achieved through their composition, which includes a significant amount of carbon and other alloying elements like manganese, chromium, and nickel. These elements enhance the material's strength, hardness, and ability to resist deformation and cracking. Furthermore, steel flat bars often undergo heat treatment processes, such as quenching and tempering, to further enhance their fatigue performance. These treatments increase the material's hardness and toughness, making it more resistant to fatigue failure. Another advantage of steel flat bars is their uniform and consistent structure along their entire length. This allows for even distribution of the cyclic loads, preventing stress concentrations and reducing the likelihood of crack initiation and propagation. Moreover, the smooth surface of steel flat bars minimizes stress concentrations and lowers the risk of fatigue failure. The absence of sharp corners or notches eliminates potential stress raisers, ensuring a more uniform distribution of the cyclic loads. In conclusion, steel flat bars are highly suitable for fatigue loading conditions due to their high strength, durability, uniform structure, and smooth surface. These properties enable them to withstand cyclic loads without significant deformation or failure, making them a reliable choice for various applications requiring fatigue resistance.

- Q:Can steel flat bars be used for making brackets or supports for HVAC systems?

- Yes, steel flat bars can be used for making brackets or supports for HVAC systems. Steel is a strong and durable material, making it suitable for supporting the weight and load of HVAC components. Steel flat bars can be easily cut, bent, and shaped to the desired dimensions, allowing for custom brackets or supports to be fabricated. Additionally, steel has excellent corrosion resistance properties, ensuring that the brackets or supports will remain stable and reliable over time. Overall, steel flat bars are a common and practical choice for manufacturing brackets or supports for HVAC systems.

- Q:What are the standard lengths available for steel flat bars?

- The standard lengths available for steel flat bars vary depending on the manufacturer and the specific requirements of the customer. However, in most cases, steel flat bars are commonly available in lengths ranging from 6 feet to 20 feet or more. These lengths are often determined by the standard sizes and dimensions set by industry standards or customer preferences. It is important to note that custom lengths can also be obtained by cutting or shearing the steel flat bar to the desired size.

- Q:How do you determine the maximum load capacity of a steel flat bar?

- To determine the maximum load capacity of a steel flat bar, there are several factors that need to be considered. Firstly, the material properties of the steel, such as its yield strength and tensile strength, play a crucial role in determining the load capacity. These properties can usually be found in engineering handbooks or from the manufacturer's specifications. The yield strength is the maximum stress that the steel can withstand before it starts to deform permanently, while the tensile strength is the maximum stress it can handle before breaking. Secondly, the dimensions of the flat bar are important. The width, thickness, and length of the bar all contribute to its load-carrying capacity. A wider and thicker bar will generally have a higher load capacity compared to a narrower and thinner one. The length of the bar also affects its load-bearing ability, as longer bars tend to be more prone to bending and sagging under load. Another factor to consider is the type of loading the flat bar will be subjected to. Different types of loads, such as evenly distributed loads or point loads, will have different effects on the bar's capacity. The supported ends of the bar also play a role, as different support conditions, such as simply supported or fixed ends, will affect its load-bearing ability. To determine the maximum load capacity, engineers often use mathematical equations, such as the Euler-Bernoulli beam theory or the yield strength formula, which take into account the material properties, dimensions, and loading conditions. These equations can help calculate the maximum load that the steel flat bar can safely withstand without failure. It is important to note that these calculations are based on theoretical assumptions and simplifications, and real-world applications may have additional factors to consider, such as safety factors, environmental conditions, and dynamic loading. Therefore, it is always recommended to consult with a qualified engineer or structural analyst to ensure accurate determination of the maximum load capacity for a specific steel flat bar application.

- Q:What type of steel is commonly used for flat bars?

- One type of steel commonly used for flat bars is mild steel. Mild steel is a low carbon steel that is highly versatile and widely available. It is known for its strength, durability, and ease of machining. Mild steel flat bars are often used in construction, manufacturing, and various applications where a strong and reliable material is required. Additionally, stainless steel is another type of steel that is commonly used for flat bars, particularly in applications that require resistance to corrosion and staining. Stainless steel flat bars are often used in the food industry, architectural projects, and marine applications.

- Q:How do steel flat bars contribute to the overall efficiency of healthcare structures?

- Steel flat bars contribute to the overall efficiency of healthcare structures by providing structural support and stability. These bars are commonly used in the construction of hospital beds, medical equipment, and other infrastructure within healthcare facilities. Their high strength and durability ensure the longevity of these structures, reducing maintenance costs and the need for frequent replacements. Additionally, steel flat bars can be easily fabricated and installed, saving time and effort during the construction process. Overall, their usage enhances the reliability and efficiency of healthcare structures, ultimately benefiting patients and healthcare professionals.

- Q:Are steel flat bars suitable for railway tracks?

- Railway tracks cannot be made from steel flat bars as they lack the required strength and structural integrity to support the weight of trains and prevent track deformations. Steel rails specifically designed for railway tracks are capable of withstanding the heavy loads and constant stress caused by moving trains. Additionally, railway tracks must be able to handle significant dynamic loads, vibrations, and thermal expansion, which steel flat bars are not designed to endure. If steel flat bars were used instead of proper railway tracks, it would pose a safety risk, leading to frequent maintenance and potential derailments due to premature wear and tear. To ensure safe and efficient train operations, it is crucial to use specialized steel rails that are specifically engineered for railway applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality and Stainless Alloyed Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords