Polyvinyl Chloride Waterproof Membrane for Roof Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of PVC Waterproofing Membrane

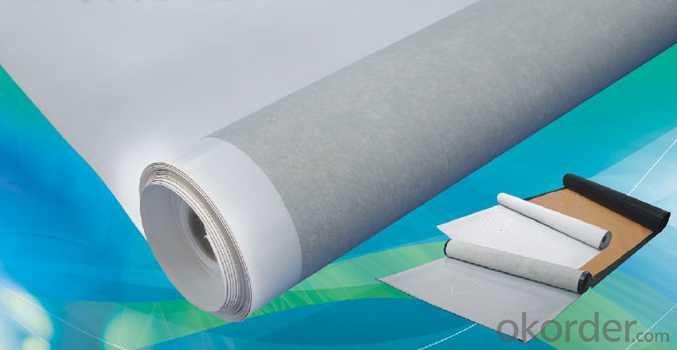

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Specification of PVC Waterproofing Membrane

Length | 20m/roll or customized |

Width | 2.05m |

Thickness | 1.2mm; 1.5mm; 2.0mm |

Type | Homogeneous, Reinforced, Fabric back |

If Exposed | Exposed and Non-exposed |

Color | White, Grey or customized |

Characteristic of PVC Waterproofing Membrane

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:Can a waterproofing membrane be used for pond or pool applications?

- Yes, a waterproofing membrane can be used for pond or pool applications. Waterproofing membranes are designed to provide a barrier against water penetration, making them an ideal choice for sealing ponds and pools. These membranes are typically made from synthetic materials such as PVC, EPDM, or TPO, which are highly resistant to water and UV rays. They are available in various thicknesses and can be customized to fit the specific dimensions of the pond or pool. Additionally, waterproofing membranes are durable and flexible, allowing them to withstand the constant exposure to water and the movement of the underlying substrate. Overall, using a waterproofing membrane for pond or pool applications can help prevent leaks, prolong the lifespan of the structure, and ensure a safe and enjoyable water environment.

- Q:Are waterproofing membranes suitable for stadium structures?

- Yes, waterproofing membranes are suitable for stadium structures. These membranes provide an effective barrier against water infiltration, protecting the structure from potential damage caused by moisture. Additionally, waterproofing membranes are flexible and can accommodate movement in the stadium's structure without compromising their effectiveness.

- Q:Is a waterproofing membrane resistant to algae or moss growth?

- A waterproofing membrane is usually resistant to the growth of algae or moss. Its purpose is to form a barrier against water infiltration, preventing moisture from seeping into the underlying structure. These membranes are typically composed of materials that are not favorable for the growth of algae or moss, such as synthetic polymers or rubberized compounds. Furthermore, they are often treated with additives that hinder the growth of organic matter, including algae or moss. Nevertheless, it is crucial to acknowledge that if the membrane is consistently exposed to moisture or damp conditions over time, it may become a breeding ground for algae or moss. Therefore, it is important to regularly maintain and clean the waterproofing membrane to ensure its longevity and effectiveness.

- Q:How is the water level rated and how many grades are used?

- 3, roof waterproof level 3: Application: general building; Waterproof layer of reasonable use of life: 10 years; Waterproof layer selection of materials: should choose three asphalt four oil asphalt waterproofing membrane, polymer modified asphalt waterproofing membrane, synthetic polymer waterproofing membrane, metal sheet, polymer modified asphalt waterproof coating, synthetic polymer waterproof coating , Fine stone concrete, flat tile, felt tile and other materials;

- Q:Does a waterproofing membrane require any specific primers or bonding agents for installation?

- Yes, a waterproofing membrane typically requires specific primers or bonding agents for proper installation. These primers or bonding agents are necessary to ensure proper adhesion and create a strong bond between the membrane and the substrate, enhancing the effectiveness and longevity of the waterproofing system.

- Q:Can waterproofing membranes be used on expansion joints?

- Yes, waterproofing membranes can be used on expansion joints. Expansion joints are designed to accommodate movement and prevent damage caused by thermal expansion or contraction of building materials. Waterproofing membranes can be applied to expansion joints to create a barrier against water infiltration, which helps to maintain the structural integrity of the joint and prevent water damage to surrounding areas. It is important to select a waterproofing membrane that is flexible and able to withstand the movement of the joint without cracking or deteriorating. Additionally, proper installation techniques should be followed to ensure a watertight seal around the expansion joint.

- Q:Can a waterproofing membrane be used on bridges?

- Yes, a waterproofing membrane can be used on bridges. It is a common practice to use waterproofing membranes on bridge decks to protect them from water infiltration, which can cause damage and deterioration over time. The membrane acts as a barrier, preventing water from penetrating the bridge deck and protecting the underlying structure.

- Q:Can a waterproofing membrane be used for sealing pipe penetrations?

- Yes, a waterproofing membrane can be used for sealing pipe penetrations. Waterproofing membranes are specially designed to create a barrier against water intrusion and can effectively seal various types of penetrations, including pipes. They are commonly used in construction projects to prevent water leaks and damage. By applying the waterproofing membrane around the pipe penetration, it creates a watertight seal that prevents water from entering or escaping through the opening. This helps to maintain the integrity of the building envelope and protect against potential water-related issues, such as leaks, mold growth, and structural damage. Additionally, waterproofing membranes are often flexible, allowing them to adapt to the shape and size of the pipe penetration, ensuring a secure and durable seal.

- Q:Polyethylene polypropylene waterproofing membrane forming. Secondary molding, what does it mean? How to distinguish?

- The second compound is, first produced or bought from the market polyethylene film, by heating the polypropylene non-woven composite up. This method is not enough heating, non-woven stickers are not strong, heating is too high, the polyethylene film damage, polyethylene plastic through the second heating to speed up his aging. Further, the polyethylene film for secondary compounding, the proportion of the recycled plastic is too high, and the anti-aging property is lowered.

- Q:Can a waterproofing membrane be used for power plants?

- Yes, a waterproofing membrane can be used for power plants. Waterproofing membranes are commonly used in various applications where water penetration needs to be prevented, and power plants are no exception. Power plants often have areas that are exposed to water, such as cooling towers, wet flue gas desulfurization systems, and other water management systems. Using a waterproofing membrane in these areas can help protect the structures and equipment from water damage, corrosion, and leaks. Additionally, waterproofing membranes can also be used in underground structures, such as basements or tunnels, which are commonly found in power plants. These membranes provide an effective barrier against water infiltration, ensuring the integrity and longevity of the structures in power plants. Therefore, utilizing a waterproofing membrane is a practical and beneficial solution for maintaining the performance and reliability of power plant facilities.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyvinyl Chloride Waterproof Membrane for Roof Filter

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords