Color Coated Steel Sheet (ASTM A755) for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:Ral 3012

Standard:AISI

Steel Grade:ASTM A755

Surface Treatment:Coated

Technique:Cold rolled, Hot dipped, Pre-painted

Export Markets:Global

Additional Info.

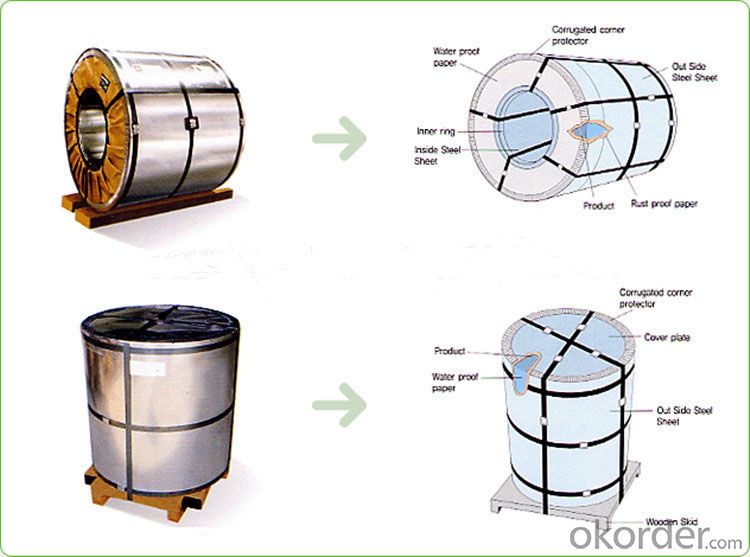

Packing:Standard Sea Worthy Package

Standard:ASTM A755

Origin:China

HS Code:72107000

Production Capacity: 18, 000~25, 000 Tons Per Month.

Product Description

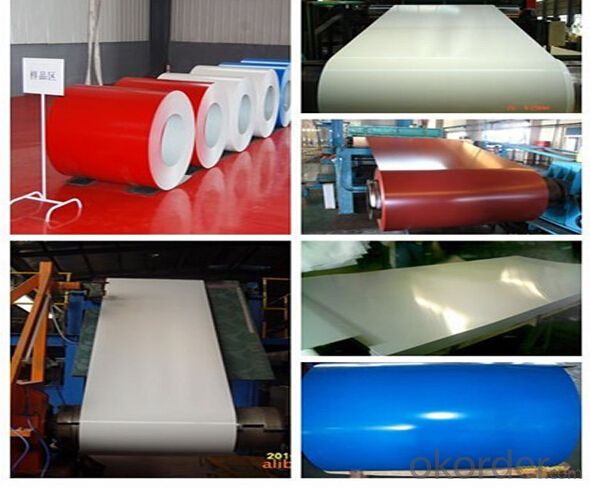

NAME: Prepainted Steel Coil\Colour Coated Coil\Coil coated steel\PPGI

SIZE:

Thickness: 0.18-1.50mm

Width: 10mm-1500mm(STD914mm,1000mm, 1200mm, 1219mm, 1250mm, 1500mm)

Thickness tolerance: +/-0.05 mm

Width tolerance: -2.0/5.0mm

ZINC, PAINT & COLOR:

Zinc coating: 60-275G/M2

Paint thickness: Top 15-25um + Back 5-10um

Paint: polyester, silicone polyester, acrylic, fluoropolymer, plastisol, or polyurethane

Color: As the RAL color standard or customer's sample

PACKING:

Coil weight: 3-10tons

ID: 508mm\610mm

Standard sea worthy package

STANDARD:

JIS G 3312, ASTM A755, EN10169,GB/T2518

Base sheet: SGCC, CGCC, DC51D+Z, Q195,etc

Quality: CQ DQ

Lifespan: 10-15 years

APPLICATION:

Outdoor: Roof\ Roof structure\Surface sheet of balcony\ Frame of window\Door\Door of garage\Roller shutter door\Booth\Persian blinds\Cabana\Refrigerated wagon and so on.

Indoor: Door\Isolater\Frame of door\Light steel structure of house\Sliding door\Folding screen\Ceiling\ Internal decoration of toilet and elevator.

Building accessories: Window panels, signboards Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q:Does anyone know how to make a steel helmet, or does anyone know where to direct me websites-wise? i've just started looking on the web for info, so when i get back here i might've already found some info, but more wouldn't hurt, especially if from people who are interested on the subject. i know nothing about metallurgy, nothing on the art of metal working etc... please help.

- Steel okorder

- Q:How do steel coils perform in extreme weather conditions?

- Steel coils are highly durable and resistant to extreme weather conditions. They can withstand intense heat, freezing temperatures, heavy rain, and strong winds without losing their structural integrity or performance.

- Q:How are steel coils used in the manufacturing of shipping containers?

- Steel coils are used in the manufacturing of shipping containers to provide strength, durability, and structural integrity. These coils are processed and shaped into the necessary components, such as walls, floors, and roofs, which are then assembled to create a sturdy container. The steel coils also allow for easy transportation and stacking of the containers, ensuring safe and efficient shipping of goods worldwide.

- Q:I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- If you're looking to make steel stronger, I can suggest 2 things: 1. If you're actually smithing the steel yourself, and forging it from hot liquid metal, then if you can get ahold of some Carbon (i have no idea where you can get some), you can add it to the molten steel to make it stronger. Sword Smiths did it all the time back in the Dark Ages. (you'll have to look up the exact Science and Process of how to do it) 2. There's a treatment for steel called Tempering. If you Temper the steel, it makes it stronger. You do this by 1st Forging what you're making. In this case, I'll use a sword. Take the Sword and re-heat it (i dont know the exact temperature) until it glows-hot. You can use a blast furnace, a campfire, or any other extreme-source of heat. Some companies use molten Salt - yes, the Condement, and dip the sword in it until it's glowing-hot. Now you have to super-cool it. This is simple, all you need is Ice water. Submerge the Sword in it, until it's cool to the touch. Now toss the Sword back into your source of extreme Heat. Get it glowing hot, and then take the sowrd out. Set it aside, and let it cool naturally. Once it's cooled, it's TEMPERED, and alot stronger. NOTE: If you stop at the ICE-WATER stage, you'll only succeed in making your Sword BRITTLE. You MUST Continue the Process once Started. - Hope this helps.

- Q:I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- I think so, I've never played classical, only acoustic and electric but my neighbor has a classical and he has all steel strings on it.

- Q:How are steel coils used in the production of steel containers?

- Steel coils are an essential component in the production of steel containers. These coils, made from flat-rolled steel, are used to create the main body of the container. Firstly, the steel coils are unwound and fed into a rolling mill, where they undergo a series of processes to shape and form the steel. This includes heating the coils to a specific temperature to make them more malleable and easier to work with. The hot coils are then passed through a series of rollers that gradually reduce their thickness and lengthen them to the desired size. This process is known as hot rolling. Once the steel coils have been rolled to the required thickness, they are then cooled and cut into sheets. These sheets are then further processed to remove any imperfections or irregularities, ensuring a smooth and uniform surface. This is done through processes such as pickling, where the sheets are treated with acid to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and smoothed, they are then formed into the shape of the container. This is typically done through a process called stamping, where the steel sheets are pressed into a mold using a hydraulic press. The mold determines the shape and size of the container, and the steel sheets are pressed against it with immense force, resulting in the desired container shape. Once the containers have been formed, they undergo various finishing processes such as welding, painting, and coating to enhance their durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers are of high quality and meet the required standards for their intended use. In summary, steel coils play a crucial role in the production of steel containers by providing the raw material from which the containers are formed. Through a series of processes, the steel coils are shaped, cut, and formed into sheets, which are then further processed and transformed into the desired container shape. The result is a durable and reliable steel container that can be used for various applications across industries.

- Q:What are the common methods of inspecting steel coils for defects?

- The common methods of inspecting steel coils for defects include visual inspection, ultrasonic testing, magnetic particle inspection, and eddy current testing.

- Q:What are the weight ranges of steel coils?

- The weight ranges of steel coils can vary widely depending on the specific type and dimensions of the coil. However, typical weight ranges for steel coils can range from a few hundred kilograms to several tons.

- Q:Which one would be stronger? And should damascus steel be tempered?Thank You

- Damascus steel is not a good choice. Gun barrels were once made of Damascus but no longer. Mono steels have come a long way in the past 100 years along with methods of tempering. The skill required to create a functional, strong, and safe Damascus steel sword is rare and extremely labor intensive. A cheap Damascus sword should never be used for cutting anything but air. While you can buy a fine Damascus sword expect to pay a high price. Although any fine sword will cost quite a bit, $500 to thousands. Modern Mono steels now out perform even traditional folded blades. Folding was to change the carbon content and not primarily for strength. Lots of info on the web, make sure to check it for yourself and don't believe the romantic notion that antique blades out perform anything made today. That's just not true.

- Q:a concrete or steel building?also, what is the density of concrete and steel? is concrete heavier in steel for the same volume?

- minorchord2000 an engineer using a non-metric measuring system - it's priceless

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Color Coated Steel Sheet (ASTM A755) for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords