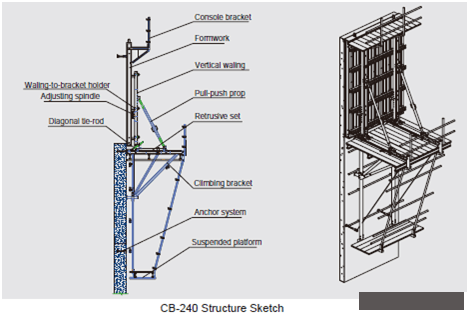

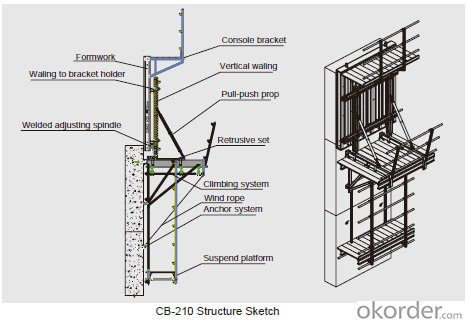

Vertical Structure Support System for Climbing Bracket CB240 & CB210

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Climbing Bracket CB240 & CB210

They are framework brackets for supporting large-area wall formwork.

Typical applications for the CB240&CB210 are pier and column/shear wall/core walll/ in the building.

CB210 has smaller size than CB240, it will be cost effective in some condition.

2. Main Features of Climbing Bracket CB240 & CB210

-High bearing capacity

-Simple moving procedure by crane

-Fast striking process without a crane

-Safe with work platform

3. Climbing Bracket CB240 & CB210 images

4. Climbing Bracket CB240 & CB210 Specifications

5. FAQ of Climbing Bracket CB240 & CB210

1) What can we do for you?

.We can ensure the quality of Climbing Bracket CB240 & CB210 and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q:Are there any regulations or standards for using steel props?

- Yes, there are regulations and standards for using steel props in construction and engineering industries. Steel props, also known as adjustable steel props or scaffolding props, are temporary support structures used to provide vertical support during construction or renovation activities. In many countries, the use of steel props is regulated by building codes and safety standards. These regulations ensure that steel props are designed, manufactured, and used in a safe and effective manner. The specific regulations and standards may vary between jurisdictions, but they generally cover various aspects of steel prop usage, including design criteria, load capacities, installation methods, and inspection requirements. For instance, the British Standard BS 4074 specifies the requirements for adjustable steel props used in construction. It outlines the manufacturing requirements, load capacities, and safety factors for steel props. It also provides guidelines for proper installation, bracing, and inspection procedures. Similarly, in the United States, the Occupational Safety and Health Administration (OSHA) sets standards for construction activities, including the use of steel props. OSHA regulations, such as 29 CFR 1926 Subpart L, provide guidelines on scaffold use, including the appropriate design, erection, and dismantling procedures for scaffolding systems, which may include steel props. These regulations and standards are in place to ensure the safety of workers and the public during construction activities. They aim to prevent accidents, collapses, and injuries that could occur due to faulty or improper use of steel props. Compliance with these regulations is typically mandatory and enforced by regulatory authorities, who may conduct inspections and issue penalties for non-compliance. Therefore, it is important for construction companies, contractors, and individuals involved in construction projects to be aware of and adhere to the regulations and standards applicable in their jurisdiction. They should ensure that steel props used on their sites meet the necessary requirements, are installed correctly, and undergo regular inspections to ensure their integrity and safety.

- Q:What are the different types of steel used in steel props?

- There are several different types of steel commonly used in steel props, each with its own unique properties and advantages. 1. Mild Steel: This is the most common type of steel used in steel props. It is relatively low in carbon content and is known for its excellent weldability and formability. Mild steel props are cost-effective and widely available, making them a popular choice for many construction projects. 2. High-strength Low-alloy (HSLA) Steel: HSLA steel props are made with a combination of carbon steel and small amounts of other elements such as vanadium or niobium. This results in higher strength and improved performance compared to mild steel props. HSLA steel props are often used in applications where additional strength and durability are required. 3. Stainless Steel: Stainless steel props are corrosion-resistant and have high strength, making them suitable for use in environments with high humidity or exposure to chemicals. They are commonly used in marine construction, food processing plants, and other applications where resistance to corrosion is essential. 4. Carbon Steel: Carbon steel props contain a higher carbon content than mild steel, which enhances their strength and hardness. They are often used in heavy-duty applications where high load-bearing capacity is required, such as supporting large structures or heavy machinery. 5. Alloy Steel: Alloy steel props are made by adding various alloying elements such as manganese, chromium, or nickel to carbon steel. This improves their mechanical properties, including strength, hardness, and wear resistance. Alloy steel props are commonly used in industrial settings, construction machinery, and mining equipment. 6. Tool Steel: Tool steel props are designed to have exceptional hardness, toughness, and wear resistance. They are used in applications where the prop needs to withstand heavy impacts or extreme wear, such as in forging dies, cutting tools, or molds. Each type of steel has its own strengths and weaknesses, and the choice of steel for steel props depends on the specific requirements of the project, including load-bearing capacity, corrosion resistance, and cost-effectiveness.

- Q:Can steel props be used for temporary support during pipeline installation?

- Yes, steel props can be used for temporary support during pipeline installation. Steel props are strong and durable, making them suitable for providing temporary support to pipelines during installation processes. They can be adjusted to the required height and are capable of bearing heavy loads. Steel props are commonly used in construction and civil engineering projects where temporary support is needed. They provide stability and ensure the safety of the pipeline during installation, preventing any potential damage or collapse.

- Q:What are the different types of steel props available?

- There are several types of steel props available, including adjustable steel props, push-pull props, tilt props, and heavy-duty steel props. Each type of prop is designed to support and stabilize vertical loads in various construction and formwork applications.

- Q:Are steel props adjustable for uneven surfaces?

- Yes, steel props are adjustable for uneven surfaces. They typically have a telescopic design that allows the length to be adjusted to accommodate different heights or uneven terrain.

- Q:What are the different surface treatments available for steel props?

- Steel props have various surface treatment options available, each with its own unique benefits and characteristics. Some of the most commonly used treatments for steel props are: 1. Hot-dip galvanizing: This method involves immersing the steel props in molten zinc, forming a protective layer that prevents rust and corrosion. Hot-dip galvanizing provides excellent durability and is ideal for outdoor use. 2. Powder coating: To apply powder coating, a dry powder is added to the steel props and then heated to create a strong and durable coating. This treatment offers a wide range of colors and finishes, enhances aesthetics, and provides protection against corrosion, chemicals, and UV rays. 3. Epoxy coating: Epoxy coating is a type of paint that contains epoxy resin, offering a resilient and long-lasting finish for steel props. It has excellent resistance to chemicals, abrasion, and corrosion, making it suitable for demanding industrial environments. 4. Paint coating: Painting steel props is a common surface treatment that allows for a variety of colors and finishes. However, it is generally less durable than other options and may require periodic maintenance or touch-ups to prevent corrosion. 5. Electroplating: Electroplating involves depositing a layer of metal, such as chrome or nickel, onto the steel props through an electrochemical process. This treatment enhances appearance and provides corrosion resistance, but it may not be as durable as other choices. 6. Anodizing: Although typically used for aluminum, anodizing can also be applied to steel props. It creates a thin protective oxide layer on the surface, improving corrosion resistance and offering various aesthetic options. The selection of a surface treatment depends on specific requirements such as intended use, environmental conditions, aesthetics, and budget. Seeking advice from professionals or suppliers can help determine the most suitable surface treatment for steel props in a particular application.

- Q:Can steel props be used for supporting temporary fencing?

- Yes, steel props can be used for supporting temporary fencing. Steel props are sturdy and durable, making them suitable for providing support to temporary fencing structures. They can be easily adjusted to the desired height and are capable of withstanding the weight and pressure exerted on the fencing. Additionally, steel props are versatile and can be used in various construction and temporary fencing applications.

- Q:In the construction of the cast-in-place floor of the fastener type steel pipe support system, which belongs to the full scaffold, or belong to the template and support system

- Formwork and support system.Full scaffolding is generally used for single storey workshop, hall and other floors, the construction of the ceiling of a large architectural decoration. By the vertical rod, bar, diagonal bracing, scissors, etc..

- Q:Can steel props be used for supporting temporary transportation infrastructure?

- Indeed, temporary transportation infrastructure can be supported by steel props. These props, which are adjustable and possess remarkable strength, can effectively bolster temporary structures like bridges, tunnels, and roadways. In construction endeavors, they are frequently employed to temporarily support structures while they are being built. The installation of steel props is a straightforward task, and they possess the capacity to withstand substantial loads, rendering them ideal for supporting transportation infrastructure. Moreover, their adaptable nature permits the adjustment of both height and angle, thereby guaranteeing stability and safety for the temporary structure.

- Q:What are the safety considerations when using steel props?

- There are several safety considerations to keep in mind when using steel props. Firstly, it is important to ensure that the props are in good condition and free from any defects or damage. Regular inspections should be conducted to identify any signs of wear or structural issues. Secondly, proper installation is crucial to maintain stability and prevent accidents. The props should be securely and correctly positioned, with appropriate bracing and shoring. Additionally, it is essential to adhere to the recommended load capacity and never exceed the maximum weight limit. Lastly, workers should receive adequate training on the safe use and handling of steel props to minimize the risk of injuries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Vertical Structure Support System for Climbing Bracket CB240 & CB210

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 60000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products