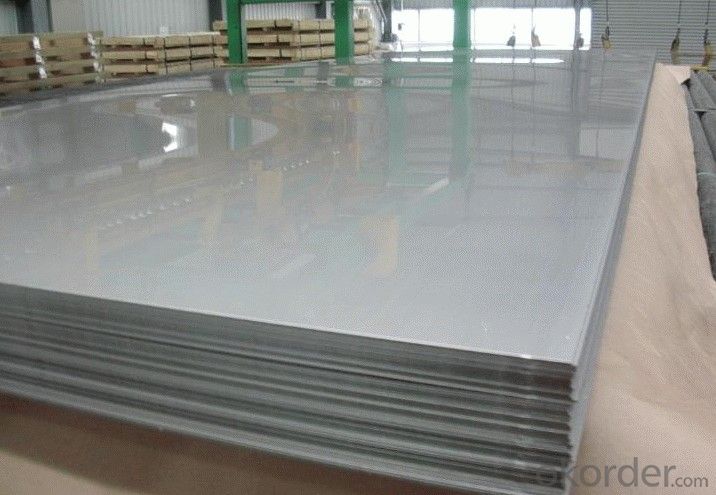

304 Stainless Steel Sheet ,Deep Drawing Board ,Wire Drawing Board ,Mirror Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

304 stainless steel wire drawing board is stainless steel surface like silk texture, this is just a kind of stainless steel processing technology. The surface is matte, carefully see there is a trace of texture, but can not touch. Than the general bright surface of stainless steel wear, looks more grade.The mirror panel, polishing liquid and polishing equipment through polishing on stainless steel surface, the surface was like a mirror clear. Uses: mainly used in building decoration, decoration, decoration, elevator industrial facilities decoration and other stainless steel products.

Produced by cold-rolled plate, flatness flatness, uniform color, good tensile ability. Ordinary ST12 grade products, its elongation rate of up to 38%, higher than the other similar products around 33%. So the product of the iron and steel can be competent for bending 180 degrees, general tension and other mechanical processing requirements. For electrical cabinet, ordinary tensile hardware, steel pipe, small pumps, auto parts etc.. Special needs to be emphasized is that of AISC Cold rolled plate of Kaiping, Guangdong VCD, DVD power amplifier manufacturer specified materials, VCD, DVD power amplifier housing requirements on the surface of the steel plate punching, and porous plate procumbent, can meet the demand for high-end customers.

2.Product characteristic:

Stainless steel raw materials after grinding and polishing the surface of the stainless steel plate with a specular gloss, there are BA, 2B, ordinary, 8K, 8K surface best

Uses: mainly used in building decoration, elevator decoration. Decoration, decoration and other industrial facilities, stainless steel series products. 316 stainless steel mirror, 316L stainless steel mirror, 304 stainless steel mirror, 301 stainless steel mirror, 201 stainless steel mirror, etc.

3.Specification:

1, by thickness classification

(1) plate (2) plate (3) plate (4) thick plate

2, according to the production method classification

(1) hot rolled sheet (2) cold rolled

3, according to the surface feature classification

(1) a galvanized sheet (2) () clad sheet (4) of a galvanized sheet (3) coated steel plate

4, by classification of uses

(1) bridge plate (2) boiler plate (3) shipbuilding plate (4) armor plate (5) automobile steel plate (6) roof plate (7) structural steel plate (8) electrical steel sheet (sheet) (9) spring plate (10) other, ordinary and mechanical structure with steel plate in common Japanese brand

4.Reference pictures:

- Q:I'm quite confused...i watched all of steel angel kurumi (the 28 episodes) and then continued to steel angel kurumi zero. it was an entire different story line with only the steel angels being the same. the world is different the guys are different, and there is a new character. Even the humor is gone. its like a whole different series. So what gives, what is the relationship between them?

- Steel Angel Zero is an OVA (Original Video Animation), a very short animation that went straight to DVD. It probably was written because Kurumi was so popular, and the producer wanted to check the waters for whether they should make a second season. It's pretty hard to keep track of what anime is which, especially in the more popular series. If you think Zero is worth zero, try Steel Angel Kurumi 2 (anime, 12 episodes), and Steel Angel Kurumi Encore (OVA, 4 episodes) as well.

- Q:In pounds per square inch what is the tensile strength of strong steel?

- The term tensile strength refers to the amount of tensile (stretching) stress a material can withstand before breaking or failing. The ultimate tensile strength of a material is calculated by dividing the area of the material tested (the cross section) by the stress placed on the material, generally expressed in terms of pounds or tons per square inch of material. Tensile strength is an important measure of a material's ability to perform in an application, and the measurement is widely used when describing the properties of metals and alloys.

- Q:Has anyone painted their appliences with stainless steel paint? I found on the internet what is called Thomas Liquid stainless steel paint. If you have used it for your kitchen appliences or cabinets, how were the results? How hard was it to apply? Would you recommend it?

- I have never heard of stainless steel paint, but I know that stainless steel is hard to clean and maintain

- Q:What are the safety precautions while handling steel coils?

- Some safety precautions while handling steel coils include wearing protective gloves and clothing to prevent cuts and scrapes, using proper lifting techniques to avoid back injuries, ensuring a clear and organized work area to prevent tripping hazards, and using appropriate equipment, such as forklifts or cranes, to safely move and stack the coils. It is also important to follow proper storage procedures to prevent the coils from falling or shifting and causing accidents.

- Q:What is the average lifespan of a steel coil storage rack?

- The average lifespan of a steel coil storage rack can vary depending on several factors such as the quality of the rack, proper maintenance, and usage conditions. However, with proper care and maintenance, a well-built steel coil storage rack can typically last anywhere from 10 to 20 years or even longer.

- Q:How are steel coils used in the production of steel containers?

- Steel coils are an essential component in the production of steel containers. These coils, made from flat-rolled steel, are used to create the main body of the container. Firstly, the steel coils are unwound and fed into a rolling mill, where they undergo a series of processes to shape and form the steel. This includes heating the coils to a specific temperature to make them more malleable and easier to work with. The hot coils are then passed through a series of rollers that gradually reduce their thickness and lengthen them to the desired size. This process is known as hot rolling. Once the steel coils have been rolled to the required thickness, they are then cooled and cut into sheets. These sheets are then further processed to remove any imperfections or irregularities, ensuring a smooth and uniform surface. This is done through processes such as pickling, where the sheets are treated with acid to remove any scale or rust, and cold rolling, where the sheets are passed through rollers at room temperature to achieve the desired thickness and surface finish. After the sheets have been cleaned and smoothed, they are then formed into the shape of the container. This is typically done through a process called stamping, where the steel sheets are pressed into a mold using a hydraulic press. The mold determines the shape and size of the container, and the steel sheets are pressed against it with immense force, resulting in the desired container shape. Once the containers have been formed, they undergo various finishing processes such as welding, painting, and coating to enhance their durability, appearance, and resistance to corrosion. These final touches ensure that the steel containers are of high quality and meet the required standards for their intended use. In summary, steel coils play a crucial role in the production of steel containers by providing the raw material from which the containers are formed. Through a series of processes, the steel coils are shaped, cut, and formed into sheets, which are then further processed and transformed into the desired container shape. The result is a durable and reliable steel container that can be used for various applications across industries.

- Q:Why is the steel tape tape head not fixed?

- There are better tape measures, heads and magnets. For measuring steel objects, one can operate long distances.

- Q:Can steel coils be painted or coated?

- Yes, steel coils can be painted or coated. Painting or coating steel coils is a common practice to enhance their aesthetic appeal, protect against corrosion, and improve durability.

- Q:What are the common manufacturing defects in steel coils?

- There are several common manufacturing defects that can occur in steel coils, including surface imperfections such as scratches, pits, or dents, dimensional inconsistencies such as uneven thickness or width, edge defects like burrs or cracks, and internal defects such as inclusions or voids. These defects can impact the quality and performance of the steel coils, and manufacturers strive to minimize these issues through quality control measures and inspections.

- Q:What is the process of galvanizing steel coils?

- The process of galvanizing steel coils involves several steps to enhance their durability and protect them from corrosion. Firstly, the steel coils are cleaned thoroughly to remove any dirt, oil, or other impurities that may be present on the surface. This is done through an acid pickling process, where the coils are immersed in a bath of diluted acid solution or treated with a chemical cleaner. This step ensures that the surface of the coils is free from any contaminants, allowing for better adhesion of the zinc coating. After the cleaning process, the coils are rinsed to remove any remaining acid or cleaner. This is crucial to prevent any adverse reactions with the next step of the process. The next step is the actual galvanization, where the cleaned coils are dipped into a bath of molten zinc. The coils are carefully passed through the zinc bath using rollers or other mechanisms to ensure that the entire surface is coated evenly. The zinc bath is maintained at a specific temperature, typically around 450°C (842°F), which allows the molten zinc to bond with the steel surface. As the coils are withdrawn from the zinc bath, excess zinc is removed by passing them through air knives or by centrifugal spinning. This helps to control the thickness of the zinc coating and ensure a uniform appearance. Once the galvanization process is complete, the steel coils are cooled down gradually to room temperature. This allows the zinc coating to solidify and bond firmly with the steel surface, creating a protective barrier against corrosion. The final step in the process is inspection and quality control. The galvanized steel coils are inspected for any defects, such as uneven coating or areas with insufficient zinc coverage. This is usually done visually or through specialized equipment that can detect any anomalies. Additionally, the coating thickness is measured to ensure it meets the required specifications. Overall, the process of galvanizing steel coils is designed to enhance their longevity and protect them from rust and corrosion. By applying a layer of zinc coating to the steel surface, the coils become more resistant to environmental factors, making them suitable for a wide range of applications in various industries.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

304 Stainless Steel Sheet ,Deep Drawing Board ,Wire Drawing Board ,Mirror Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords