Insulating Fire Bricks GJM26 for High Temperature Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What it the Insulating Fire Brick?

Insulating fire bricks (IFBs) are called soft bricks comparing to hard bricks or Fireclay bricks and they are light in weight. Insulating fire brick can be easily cut by handheld hack saw or other hand tools like chisel. Insulating firebricks have high porous rate and have excellent insulating properties.

What are the applications of Insulating Fire Brick?

Glass Industries

Ceramics Industries

Electrolytic Aluminum Industries

Iron & Steel Industries

Non-Ferrous Metals Industries

Power Generation Industries

Primary hot surface linings

Sulphur recovery equipment

Cracking Furnace; Conversion Furnace

Heating equipment or Heating Furnace, Even-heating Furnace, Heat-processing Furnace

What are the excellent features of Insulating Fire Brick?

High heat resistance and durability

Excellent insulating properties

Excellent resistance to thermal shock

Low thermal conductivity

Low heat storage

Excellent construction/compressive strength

Particularly suited to highest temperature applications above 1600°C or 2800°F

Structural integrity capable of dealing with erosive and abrasive environments

Low impurity

Precise dimensions

Image of Insulating Fire Brick

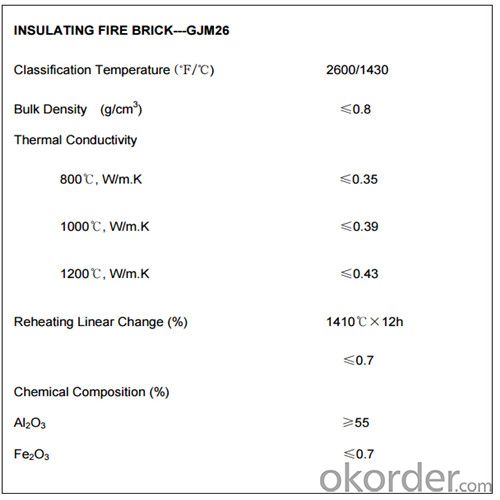

Technical Data of Insulating Fire Brick

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q:What is the typical thermal shock resistance of an insulating fire brick?

- The typical thermal shock resistance of an insulating fire brick can vary depending on the specific composition and manufacturing process. However, in general, insulating fire bricks are designed to have high thermal shock resistance. These bricks are often made from lightweight materials such as alumina, silica, and other refractory compounds, which possess excellent thermal insulation properties. Insulating fire bricks are engineered to withstand rapid temperature changes without cracking or breaking. They can typically endure thermal shocks caused by sudden exposure to extreme heat or cold, as well as rapid heating or cooling cycles. The thermal shock resistance of insulating fire bricks is crucial in applications where they are exposed to fluctuating temperatures, such as in furnaces, kilns, and other high-temperature environments. While there is no universally standardized value for the thermal shock resistance of insulating fire bricks, they are typically designed to withstand thermal shocks of several hundred degrees Celsius without significant damage. Some high-quality insulating fire bricks can even tolerate thermal shocks of up to 1000°C or more. It is important to note that the specific thermal shock resistance of an insulating fire brick might also depend on factors such as the brick's thickness, density, and overall quality. Therefore, it is advisable to consult the manufacturer's specifications or conduct specific tests to determine the exact thermal shock resistance of a particular insulating fire brick.

- Q:Are insulating fire bricks resistant to high-velocity gas flow erosion?

- Yes, insulating fire bricks are generally resistant to high-velocity gas flow erosion. These bricks are designed to withstand high temperatures and are made from materials that can withstand the erosive effects of gases flowing at high velocities. However, the resistance may vary depending on the specific composition and quality of the fire bricks.

- Q:Do insulating fire bricks emit any harmful substances when heated?

- Insulating fire bricks do not emit any harmful substances when heated. These bricks are made from materials such as alumina, silica, and other refractory materials, which are known for their high resistance to heat and chemical reactions. When exposed to high temperatures, these bricks do not release any toxic fumes or gases. They are designed to be used in various high-temperature applications, such as kilns, furnaces, and fireplaces, where they can withstand extreme temperatures without releasing any harmful substances. Therefore, insulating fire bricks are considered safe for use and do not pose any health risks when heated.

- Q:Can insulating fire bricks be used in ceramic fiber modules?

- No, insulating fire bricks cannot be used in ceramic fiber modules. Ceramic fiber modules are typically made from refractory ceramic fibers, which are lightweight and have excellent insulating properties. Insulating fire bricks, on the other hand, are dense bricks made from refractory materials like clay or silica, and they are not flexible or adaptable like ceramic fiber modules.

- Q:Are insulating fire bricks resistant to weathering?

- Yes, insulating fire bricks are resistant to weathering. Insulating fire bricks are made from high-quality refractory materials that are designed to withstand extreme temperatures and harsh weather conditions. They are specifically engineered to have excellent resistance to thermal shock, erosion, and corrosion caused by exposure to various weather elements such as rain, snow, wind, and sunlight. Additionally, insulating fire bricks are also resistant to chemical attacks, making them highly durable and suitable for long-term use in outdoor applications. Overall, their robust composition and resistance to weathering make insulating fire bricks a reliable choice for insulation and construction purposes in outdoor environments.

- Q:How do insulating fire bricks prevent heat loss?

- Insulating fire bricks have been specifically engineered to prevent the loss of heat in a wide range of applications. These bricks are crafted from refractory materials that possess exceptional thermal insulation properties. Their structure contains small air pockets that serve to minimize the transfer of heat through conduction and convection. One effective method employed by insulating fire bricks to prevent heat loss involves their low thermal conductivity. When compared to other materials, these bricks exhibit significantly lower thermal conductivity, which means they are less efficient at transmitting heat. This characteristic enables them to function as a barrier, impeding the transfer of heat from one side of the brick to the other. Moreover, the presence of tiny air pockets within the bricks creates a thermal barrier. Due to the poor heat-conducting properties of air, these air pockets effectively trap heat within the brick, preventing its escape. This insulation property aids in retaining heat within the desired area, thereby reducing heat loss and enhancing energy efficiency. Furthermore, insulating fire bricks possess the ability to prevent heat loss through heat reflection. These bricks boast a high emissivity, enabling them to reflect a considerable amount of heat back into the desired space. This reflection works to maintain a higher temperature within the area and prevent the dissipation of heat. In conclusion, insulating fire bricks effectively prevent heat loss by diminishing conduction and convection through their low thermal conductivity, confining heat within small air pockets, and reflecting heat back into the desired space. These bricks play an indispensable role in diverse applications where heat retention is of utmost importance, such as kilns, furnaces, and other high-temperature environments.

- Q:Do insulating fire bricks have any impact on indoor air quality?

- Insulating fire bricks do not have any direct impact on indoor air quality. These bricks are made from materials that are generally inert and do not release any harmful substances or volatile organic compounds into the air. However, it is important to note that the overall indoor air quality can be influenced by various factors, such as the presence of other materials, pollutants, or ventilation systems in the surrounding environment.

- Q:Are insulating fire bricks suitable for applications with high mechanical stress?

- Insulating fire bricks are generally not suitable for applications that experience high levels of mechanical stress. They are specifically designed to offer exceptional thermal insulation and are constructed from lightweight materials like clay, ceramic fibers, or vermiculite. Despite their excellent insulation capabilities, they do not possess the same strength or durability as structural fire bricks or other refractory materials. When it comes to applications that involve heavy mechanical stress, such as robust furnaces, kilns, or industrial processes with significant movement or loading, fire bricks capable of withstanding these forces are necessary. These applications typically rely on dense fire bricks or refractory materials that exhibit greater compressive strength and resistance to mechanical stress. Opting for insulating fire bricks in applications with high mechanical stress can result in issues such as cracking, crumbling, or premature failure of the bricks. This compromises the system's integrity and efficiency. Therefore, it is crucial to carefully select the appropriate fire bricks or refractory materials that can endure the specific mechanical stress requirements of the application.

- Q:Are insulating fire bricks suitable for use in coke ovens?

- Coke ovens demand bricks capable of enduring exceedingly high temperatures and harsh chemical surroundings, rendering insulating fire bricks unsuitable for such purposes. Insulating fire bricks are primarily engineered to offer thermal insulation and lack the capability to withstand the heat and chemical exposure inherent in coke ovens. Consequently, it becomes imperative to employ refractory bricks custom-built for coke ovens, boasting exceptional resistance to temperature, chemical assaults, and thermal shock. Typically composed of robust materials like silica, alumina, and carbon, these refractory bricks exhibit remarkable resilience within the formidable conditions prevalent in coke ovens.

- Q:Can insulating fire bricks be used in combination with other insulation materials?

- Yes, insulating fire bricks can be used in combination with other insulation materials. Insulating fire bricks are known for their excellent thermal insulation properties and can be used to effectively reduce heat transfer in various applications such as kilns, furnaces, and fireplaces. However, in some cases, additional insulation may be required to achieve optimal thermal efficiency. Combining insulating fire bricks with other insulation materials can further enhance the overall insulation performance. For example, ceramic fiber blankets or boards can be used alongside insulating fire bricks to provide additional insulation and to fill any gaps or joints between the bricks. This combination can help minimize heat loss and improve energy efficiency. Furthermore, using multiple insulation materials can also provide other benefits such as increased fire resistance, improved sound insulation, and enhanced structural integrity. By utilizing different insulation materials in combination, it is possible to create a more effective insulation system that meets specific requirements for different applications. It is important to consider the compatibility and compatibility of the different insulation materials when combining them. Each material may have different thermal properties, density, and installation requirements, so it is crucial to follow the manufacturer's recommendations and guidelines for proper installation. In summary, insulating fire bricks can be used in combination with other insulation materials to enhance thermal insulation and improve overall performance in various applications. However, it is essential to ensure compatibility and follow proper installation guidelines for optimal results.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Insulating Fire Bricks GJM26 for High Temperature Furnace

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords