Lightgage Steel Joist Automatic Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Brief Introduction of Our Company

Our company specializes in manufacturing cold-pressing steel profile mechanical equipment, cold-pressing structural section, high- frequency welding machine set, inert gas arc welding machine set, pipe bending machine, metal pipe circular saw machine, chamfering machine, pipe end forming machine, conveying appliance, elevator guide rail assistant processing equipment, dust-removing equipment, all kinds of conveying equipment parts and non-standard machinery products.

Fundamental functions of cold roll forming machine

The adjustable and speed changeable equipment is used to roll various kinds of profile materials. It uses decelerator to transmit each gear case in the main machine. The upper and lower two universal rotational axes on each channel drive each roller in arch frame to roll shaping. The number of forming lines is decided on the demand of sectional design or clients'. The line is equipped with automatic feeder and guide feeder. Adopting hydraulic pressure or pneumatic to realize automatic tracking cutting and unloading. It also adopted arbitrarily scale structural section of material receiving station and electric control system with synchronized movement.

Above-mentioned is our factory’s cold roll forming machine which has been manufactured. In this field, our factory has accumulated a great quality of equipments and mould materials. In no exceptional circumstances, our company can give you one package service including comprehensive technology, quality assurance, and reasonable price, finishing designing, creating, debugging and after-sale service. We are willing to deliberative discuss and cooperate with you about the exploitation of the varieties of profile steel. We are earnestly welcome you to our factory to have a field trip, we can offer you all kinds of product introduction and equipments technical reference.

Thickness: 0.15mm - 4.00mm

coil Width: 11mm-1500mm

Zinc coating: Z80 - Z275/m2

CID: 508 or 610mm

Standard: EN, JIS, GB

Grade: DX51D, SGCC, Cs-B, S280, S320, S350, S380, DQ, DDQ, Q195

Skinpassed: If required

Surface processing: Regular spangle, Minimized spangle, Zero spangle, bright spangle

Surface chemical processing: Chromate, un-chromate passivation and fingerprint resistant treatment;

slight oiled or non-oiled

3.Image

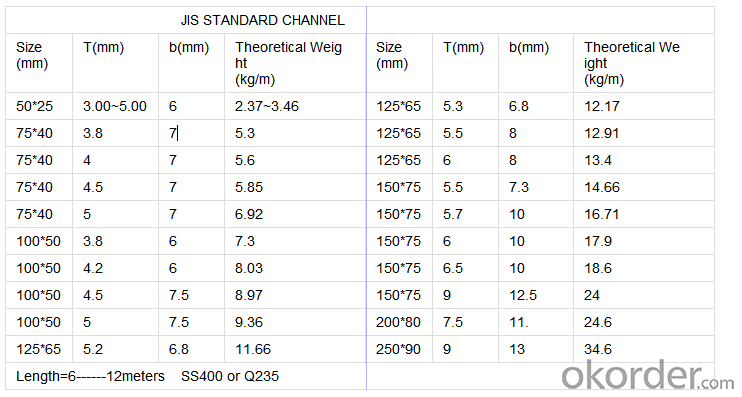

4.Detailed Specification

5.FAQ

Package: Standard seaworthy export packing.4 eye bands and 4 circumferential bands in steel, galvanized metal fluted rings on inner and outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection. Outer edges, galvanized metal & waterproof paper wall protection disk, galvanized metal & waterproof paper around circumference and bore protection.

Usage: Galvanized steel coil products are mainly applied to building, light industry, automobile, agriculture and animal husbandry fishery . In construction industry, it is mainly used to produce anti-corrosion of industrial and civil building roof, roof grille. In light industries it can be used as appliances shell, civil chimney, kitchenware, etc Farming fisheries mainly used as food storage, the seafood frozen processing equipment of meat, Business mainly used as materials of storage, packing equipment etc..

- Q:The construction of the lightweight steel keel gypsum board ceiling

- With a large sample can be expressed, draw the main keel, and then draw the vice keel, a few lines that on the line.

- Q:Why the ceiling keel

- Ceiling keel is what we often see the ceiling, especially the shape of the ceiling, are made of keel frame, and then covered with gypsum board made. Ceiling keel is made of light steel, for the ceiling of the main material, it is connected with the floor through the screw, used to fix the ceiling or objects.

- Q:140 square meters light steel keel double gypsum board ceiling fee, material costs about how much money

- The general cost of about 4,000 materials, first-line brand of materials costs around 7000, labor costs about 3000-4500 between ...

- Q:38 light steel keel standard thickness is how much? Built-in 38 light steel dragon thickness to achieve how much to meet the requirements?

- 1-1.2mm thick

- Q:Light steel keel ceiling specifications require boom length greater than 1500MM to add anti-support, what is anti-support? How to set up? The best specific construction node map, thank you!

- Anti-support can play what role

- Q:Office building silicon calcium board ceiling, the actual construction practices: light steel keel spacing 1000mm, small keel spacing 600mm meet the requirements

- 5, the installation of sub-keel 1> has been played by a good sub-keel sub-line, card sub-keel hanging pendant. 2> hanging sub-keel: according to the provisions of the provisions of the keel spacing, the sub-keel hanging hanging on the main keel, the design requirements, the general spacing of 500mm-600mm. 3> When the length of the keel to be a number of continuation of a long time, with the keel connection, hanging in the keel at the same time the connection, straighten the fixed. ?Install the cover panel, the installation of the panel before the end of the terminal equipment must be located on the ground and the various pipeline inspection and acceptance, before allowing the installation of the panel. Cover plate and light steel keel fixed method is: Light steel keel skeleton after acceptance, began to install the first layer of cement fiberboard. First in accordance with the room space on the cement fiber board layout, layout is not allowed to appear below 100mm slats. After the completion of the version, according to the layout placed cement fiber board, and with self-tapping wire fixed firmly. Self-tapping screw spacing of 150-170mm. After the completion of the first layer of cement fiberboard, should check the flatness of the allowable error should be controlled within 3mm. The first layer of cement fiberboard after the acceptance of the installation has been compressed composite panels, the installation of the use of adhesive method, the installation of the first two sides and then the middle.

- Q:Whether the ceiling light steel keel has the raw material inspection standard

- Ceiling light steel keel with raw material testing standards, ceiling light steel keel thickness requirements

- Q:Construction schedule of light steel keel ceiling

- How much area? What shape? Elaborate

- Q:Light steel keel is a flat ceiling or integrated ceiling?

- Light steel keel skeleton is widely used in the decoration of the ceiling can use light steel keel skeleton But in order to facilitate the construction, often the ceiling keel will be used to other materials or the use of other materials and light steel keel construction

- Q:What is a man ceiling, what is not a man ceiling?

- Are here you find yourself (a) the structure of the suspended ceiling Suspended roof generally consists of three parts: boom, skeleton, surface layer. 1. Boom (1) the role of boom: to withstand the ceiling layer and the backbone of the load, and this tea to the roof of the load-bearing structure. (2) the material of the boom: most of the use of steel. 2. Skeleton The role of the skeleton: to withstand the load of the ceiling layer, and the load through the boom to the roof load bearing structure. Skeleton of the material: a wooden skeleton, light steel dragon skeleton, aluminum dragon skeleton and so on. The structure of the skeleton consists of the main keel, the sub keel and the joist, the second grid, and the small frame. Light steel keel and aluminum alloy keel in the T-type, U-type, LT-type and all kinds of special keel and so on. 3. Surface layer The role of the surface layer: decorative interior space, as well as sound absorption, reflection and other functions. Surface layer of materials: paper gypsum board, fiberboard, plywood, calcium-plastic plate, mineral wool sound-absorbing, aluminum and other metal plate, PVC plastic plate. The form of the surface layer: bar, rectangular and so on.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Lightgage Steel Joist Automatic Cold Roll Forming Machine

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 300000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords