Building Material Drywall Metal Stud In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

purlin and wall beam of steel structure building

The C-shaped purlins have excellent anti-bending property and are easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Product Advantages:

(1). Design according to customers’ requirements

(2). Manufacture under complete quality control system---ISO9001:2008

(3). Installation with instruction of experienced engineers

(4). Easy to assemble and dismantle

(5). Eco-friendly material: can be used for several times and can be recycled

(6). Shorter construction period, longer using time

(7). High strength and stiffness, high weight bearing.

Main Product Features:

Height: 80-400mm

Thickness: 1.5-3.0mm

Length: As customers’ requirements.

Material: Hot rolled or galvanized Q235/Q345

Surface: Painted or Galvanized.

Punch: Can be punched as customer's drawing

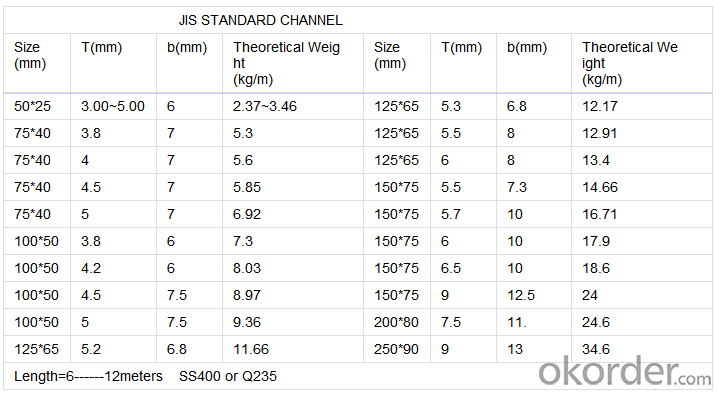

Product Specifications:

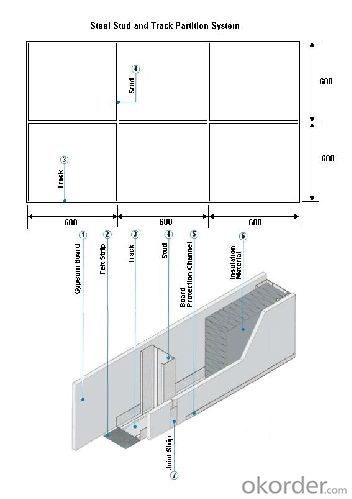

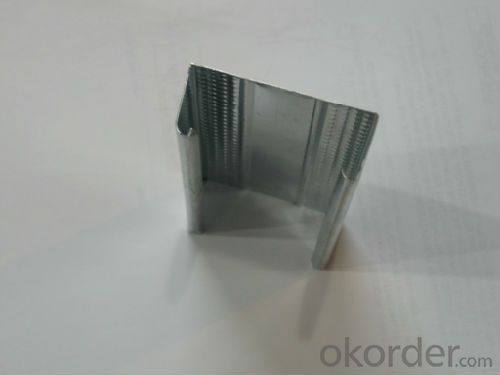

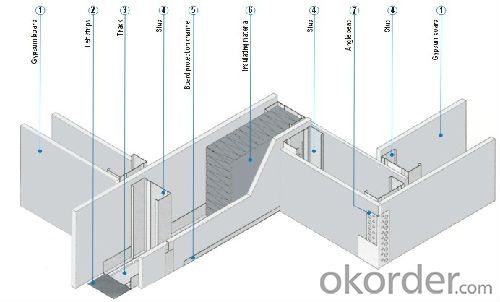

Images:

- Q:How to construct double - sided double gypsum board partition wall

- Installation of vertical keel, light steel vertical keel. Keel must be vertical, vertical keel inserted at both ends along the top keel and along the keel, adjust the vertical and positioning accuracy, with a core pulling rivets fixed.

- Q:Home to do light steel keel partition sound insulation, dare not use glass wool, with sponge or benzene as a filler for what kind of noise, good environmental protection

- Home with several levels? You can use benzene board, in a good extrusion, in the good is the polyurethane and phenolic, the cost will be high. Phenolic is nonflammable. Benzene and extruded can not reach fire

- Q:What is the pros and cons of a brick or a gypsum board?

- Wall, then the sound is very important, otherwise the side of the talk there all heard, this wall is very embarrassing. Light gypsum board, of course, can not be soundproof, the key is to choose the appropriate sound insulation cotton, and now people are more popular in the interior decoration is the gradient of sound-absorbing cotton, from environmental protection, fire, sound-absorbing efficiency and other considerations, gradient sound-absorbing cotton are present Home, office decoration more appropriate, such as the larger domestic conference center are using this sound insulation material.

- Q:Light steel keel partition wall door how to do

- The wall keel to use the national standard light steel wall keel - the thickness of the strength of only;

- Q:75 series of light steel keel wall double-sided double-layer 12 thick plaster board filled with sound insulation noise can reach the number of decibels

- Single-layer gypsum board sound insulation is poor, for example: 12mm thick, surface density of 10Kg / m 2 or so of paper gypsum board standard weighting noise C = 29dB. Even if the four layers of such gypsum board stack and together in the sound insulation on the theoretical Rw can only reach 41 dB. If the paper gypsum board made of double-wall structure, the sound insulation can be improved. Such as the above four layers of paper gypsum board made 75mm light steel keel double double wall, Rw can reach 44dB. If the cavity is filled with cotton, Rw can be increased to 50dB.

- Q:Lightproof wall how to fire

- And light steel keel installation door is the same light steel keel door frame after doing the light steel keel and then do a fixed two-layer woodworking board as a door cover and then the fire door fixed in the woodworking board or in the light steel keel fixed channel steel Made the door sets and then fixed fire doors or not the first gypsum board in the light steel keel on the back of the fixed fire door or with a channel or angle or simply use a wooden fire door

- Q:Use light steel keel to do the shelf, install the glass partition wall, this process is feasible? How about construction?

- Yes, according to the provisions of the standard fixed light steel keel, glass fixed hole, to ensure that the glass transparent and clean, surrounded by transparent glass glue. In the space can be added to the items and so on

- Q:Waterproof gypsum board for toilet partition and paste tile installation steps?

- Waterproof gypsum board called calcium silicate board; more common brands are Edite board, silver special board, gold palace board 1, the use of U75 thick (or national standard) wall light steel keel; heaven and earth keel and vertical keel are using the same model and thickness. U38 type through the keel can be used to strengthen. Vertical keel center spacing of 400MM; use of special light steel keel calipers connected fixed. 2, the use of double-sided double-sided panel technology construction, must be the same layer of different layers of wrong stitching; that is, the bathroom wall keel positive and negative were closed a layer of waterproof gypsum board. With special Tektronix special 4 * 20 anti-rust self-tapping screws. Screw spacing of not more than 20CM.

- Q:Light steel keel cut off the keel and the ground with what fixed?

- Expansion bolt or pad on a layer of blockboard (brush fire anti-corrosion coating) with 50 steel row nail directly on the ground

- Q:Decoration decoration works Light steel keel wall, layer 4 meters high thickness What are the requirements? There is no specific specification?

- Save material, reduce human input The use of the fixed screw of the keel and the angle of the fixed support column are used as the reinforcement of the ridge of the ridge, which changes the traditional construction method of embedding steel and fixed expansion bolts in the ridge, saving the material and reducing the manpower Of the input.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Building Material Drywall Metal Stud In China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 g/m

- Supply Capability:

- 300000 g/m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords