PVC Electrical Tape With 190 Mircon Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape With 190 Mircon Thickness

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape With 190 Mircon Thickness

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape With 190 Mircon Thickness

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape With 190 Mircon Thickness

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

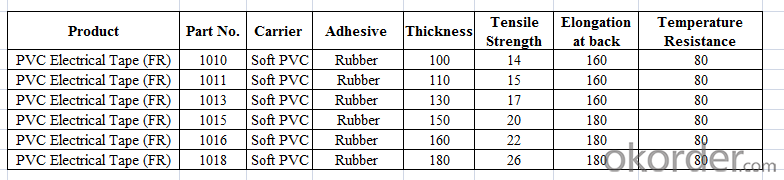

Technical Data of PVC Electrical Tape With 190 Mircon Thickness

Product Show of PVC Electrical Tape With 190 Mircon Thickness

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q:Can packaging tape be used for sealing plastic clamshell packaging?

- Yes, packaging tape can be used for sealing plastic clamshell packaging. It provides a strong and secure seal to keep the contents of the packaging safe and protected.

- Q:Does packaging tape come in different allergen-free options?

- Indeed, various allergen-free alternatives exist for packaging tape. Numerous manufacturers provide packaging tape that is explicitly formulated to be hypoallergenic, devoid of typical allergens like latex, gluten, and other potential irritants. These options without allergens prove especially advantageous for individuals with sensitive skin or allergies. It is highly advisable to thoroughly peruse the product labels or descriptions to guarantee that the packaging tape aligns with your precise allergen-free needs.

- Q:Is packaging tape safe to use on painted furniture?

- Yes, packaging tape is generally safe to use on painted furniture. It is designed to adhere to various surfaces, including painted surfaces, without causing damage or leaving residue when properly applied and removed. However, it is always recommended to test a small, inconspicuous area first to ensure compatibility and to handle the tape with care to avoid any potential paint or finish peeling.

- Q:What is the difference between acrylic and hot melt packaging tape?

- Sealing boxes and packages commonly involve the use of acrylic and hot melt packaging tapes, but they differ significantly in their adhesive properties and performance. Acrylic packaging tape boasts clarity and transparency, making it perfect for situations where package appearance matters. It also resists yellowing and aging, ensuring that it remains clear and does not become brittle over time. With a strong initial tack, acrylic tape adheres quickly to surfaces upon application. However, it may not perform as well in extreme temperatures, as its adhesive strength can diminish when exposed to high heat or cold conditions. In contrast, hot melt packaging tape consists of a synthetic rubber adhesive that is applied as a hot liquid. This tape offers superior adhesion and bond strength, making it suitable for heavy-duty or challenging packaging tasks. It excels in temperature resistance, maintaining its adhesive properties even in extreme conditions. Additionally, hot melt tape is known for its quick and effortless release, making it convenient for high-volume packaging operations. In conclusion, acrylic and hot melt packaging tapes are both effective for sealing boxes, but they have distinct advantages and disadvantages. Acrylic tape is ideal for situations prioritizing clarity, aging resistance, and initial tack. On the other hand, hot melt tape excels in adhesion strength, temperature resistance, and ease of use. Ultimately, the choice between the two depends on the specific requirements and conditions of the packaging task at hand.

- Q:Can packaging tape be used for sealing packages with electronics or electrical components?

- Sealing packages containing electronics or electrical components with packaging tape is possible. However, it is essential to understand that not all packaging tapes are suitable for this purpose. To ensure the safety of the items, it is advised to opt for an anti-static or ESD-safe tape. These tapes are specifically crafted to shield sensitive electronic components from static electricity during transportation or handling. Using regular packaging tape lacking anti-static properties may expose the electronics to the risk of static discharge, potentially leading to damage or compromised performance. Therefore, it is crucial to carefully assess the specific requirements of the electronics being packaged and select an appropriate tape accordingly, guaranteeing their protection.

- Q:Can packaging tape be used for sealing medical or pharmaceutical supplies?

- Packaging tape is not typically recommended for sealing medical or pharmaceutical supplies. Medical and pharmaceutical supplies require a higher level of sterility and protection from contamination. Packaging tape may not provide the necessary level of security and protection needed for these supplies. Instead, medical and pharmaceutical supplies are typically sealed using specialized medical-grade packaging materials such as medical adhesive tapes, tamper-evident seals, or sterile packaging. These materials are specifically designed to meet the stringent requirements of the healthcare industry, ensuring the integrity and safety of the supplies. Using packaging tape for sealing medical or pharmaceutical supplies can compromise their sterility and increase the risk of contamination, which could have serious consequences for patients' health. It is crucial to adhere to industry standards and guidelines when it comes to the packaging and sealing of medical and pharmaceutical supplies to maintain their quality and safety.

- Q:Does packaging tape come in different dispenser options for ease of use?

- Yes, packaging tape does come in different dispenser options for ease of use. There are various types of dispensers available, including handheld tape guns, tabletop dispensers, and automatic tape dispensers, each designed to provide convenience and efficiency while using packaging tape.

- Q:Can packaging tape be used for outdoor applications?

- Yes, packaging tape can be used for outdoor applications. However, it is important to choose a tape specifically designed for outdoor use, as it needs to be weather-resistant and durable to withstand various environmental conditions such as rain, sunlight, and temperature fluctuations.

- Q:How do I prevent packaging tape from peeling off?

- In order to prevent packaging tape from peeling off, there are several steps that can be taken: 1. Surface cleanliness is crucial: Prior to applying the tape, it is essential to ensure that the surface is thoroughly cleaned and devoid of any dust, dirt, or moisture. Wipe the surface using a clean cloth or paper towel and ensure it is completely dry. 2. Select the appropriate tape: It is important to use a high-quality packaging tape specifically designed for secure adhesion. Look for tapes with robust adhesive properties and a durable backing material. 3. Exert pressure: Once the tape has been applied to the surface, firmly apply pressure along its entire length using your hands or a roller. This will aid in forming a secure bond between the adhesive and the surface, preventing any peeling. 4. Employ additional tape: If there are concerns about the tape peeling off, it is possible to reinforce it by applying extra tape along the edges or corners. This will provide additional strength and stability to the initial tape. 5. Steer clear of extreme temperatures: Extreme temperatures can adversely affect the adhesive properties of the tape, resulting in peeling. It is advisable to avoid storing or using packages in areas with excessive heat, cold, or humidity. 6. Proper package storage: If packages are being stored or shipped, it is important to ensure they are kept in a cool, dry location. Avoid stacking heavy objects on top of them, as this can exert pressure on the tape and cause it to peel off. By adhering to these steps, it is possible to guarantee that the packaging tape remains securely in place, preventing any undesired peeling.

- Q:How does packaging tape perform in high-temperature conditions?

- Packaging tape typically functions well in high-temperature settings, but its effectiveness can differ depending on the specific type and quality of the tape. Most packaging tapes are engineered to endure a range of temperatures and are generally resistant to heat up to a certain degree. However, it is important to note that extreme temperatures, particularly those surpassing the tape's specified heat resistance limit, can impact its adhesive properties and overall performance. When exposed to high temperatures, the adhesive on packaging tape may soften or weaken, leading to reduced bonding strength and potential tape failure. This can result in packages opening or becoming less secure during transportation or storage. Additionally, heat can cause the tape to lose flexibility, making it more susceptible to cracking or breaking. Thus, it is vital to choose packaging tape specifically designed for high-temperature environments if there is anticipated exposure to extreme heat. Certain types of packaging tape, such as fiberglass-reinforced or high-temperature resistant tapes, are better suited for enduring high temperatures. These tapes are often manufactured with special adhesives and materials that provide enhanced heat resistance and improved performance in extreme conditions. They are designed to maintain their adhesive strength, bonding capability, and structural integrity even when confronted with elevated temperatures. In conclusion, although packaging tape can generally endure high-temperature conditions, its performance may be compromised when subjected to extreme heat. Utilizing tapes specifically designed for high-temperature environments can help ensure optimal performance and securely seal packages even in challenging conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Electrical Tape With 190 Mircon Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords