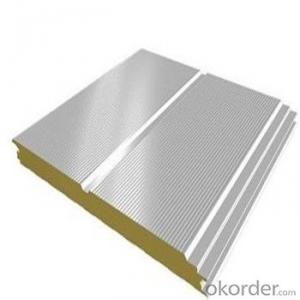

Firepoof Rockwool Sandwich Panel with CMAX Logo

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Firepoof rockwool sandwich panel with low price

1.Sound Insulation

2.Fireproof,

3. Anti-earthquake

Firepoof rockwool sandwich panel with low price

Polystyrene (EPS) Sandwich Panel

Polystyrene sandwich panel (EPS Sandwich Panel) is a new type of construction panel which made of outer layer both sides of preprinted steel coil and inner layer of polystyrene.

Character:

1. Light weight, easy to install, short work cycle, lower cost, high-capacity.

2. High stiffness and intensity.

3. Flexible for using

Application:

warehouse, gymnasium, exhibition halls, airport,movable dwellings, refrigerator.

Product series:

Rock wool (mineral wool) Sandwich Panel

Rock wool sandwich panel is applicable to project with fairly-high demand upon fire protection. All of this guaranteed the rock wool sandwich panel has a good bearing capability.

Excellent fire resistance:

The fireproofing margin of rock wool sandwich panel is as below take the wall panel as the example.

Thickness: 100mm (REI) 120mins, 75mm (REI) 60mins, 50mm (REI) 30mins

The fireproof degree of rock wool panels of 50-75-100mm are 0/1 (with their fire-proof degrees from high to low is 0,1,2,3,4,5).

Feature:

1. the ability of the fire-proofing of rock wool sandwich panel is over1000°C for the rock wool is the non-fire material.

2. good future in noise reduction, special suitable for the place where is high requirement in the sound insulation.

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q:Are sandwich panels suitable for retail outlets?

- Sandwich panels, consisting of two rigid layers and a core material, are ideal for retail outlets. With their strength and durability, the rigid layers ensure longevity, while the core material provides insulation and soundproofing. In a retail setting, sandwich panels serve various purposes. They can serve as sleek and modern exterior cladding, enhancing the building's appearance. Additionally, they can be utilized for interior walls and partitions, creating distinct areas within the store. The installation of sandwich panels is effortless, and they can be tailored to meet the specific requirements of the retail outlet. They can be painted or adorned to align with the store's branding and aesthetics. Moreover, their lightweight nature enables easy transportation and assembly, making them a cost-effective choice. The benefits of sandwich panels extend beyond aesthetics. They offer exceptional thermal insulation, ensuring a comfortable shopping experience regardless of the season. This leads to energy savings and a pleasant environment for customers. Ultimately, sandwich panels are a suitable option for retail outlets due to their durability, versatility, and energy-efficient properties. They provide an appealing and functional solution for both the store's exterior and interior.

- Q:Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q:I would like to open a 500 square meters processing sandwich panels. Color steel mills to invest much money

- Light steel plant roof static load can be divided into the following . the roof for the single-layer + cotton insulation, 0.20KN / M. the roof for the double board + insulation cotton, 0.25KN / M. the roof for the foam sandwich panels, if 50 thick, 0.3KN / M2 specific calculation, assuming purlin per meter specific gravity of . the distance is 1.. then converted to 7 / 1.5 = 5 kg or so insulation cotton generally in 1 kg, pull the sub-component 2 kg, single Floor panel 0.5 thick -0.5 * 7.85 = 4 kg then the roof of a single board + insulation cotton, constant load of 5 +1 +2 +4 = 12 kg per square meter of the actual design time to enlarge the point, take a 0.. Otherwise your trial is also very sad to give you a reference, hope useful

- Q:Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

- Q:What are the different types and uses of clean color steel plates?

- Playing glass glue, with a little better quality.

- Q:Color steel sandwich panels and color steel plate What is the difference

- Excuse me, where are you in? Indoor insulation is generally made of "polystyrene foam board", the general thickness is 2..3 cm thick, you can understand clearly, in the end is how thick the foam board (when playing screw holes, can be found is thick thick foam board) The There is that you can use .7 inside the expansion screw, to the hardware store to find can match. You can also use welding, then a long screw, is also very simple.

- Q:What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

- Q:Own balcony capped, with the kind of sandwich panels better, EPS sandwich panels or rock wool sandwich panels, or other kind of sandwich panels?

- Safety Management 2. Civilized construction. Fastener steel scaffold 4. Door steel scaffold 5. Bowl button steel pipe scaffolding 6. Socket type plate fastener type steel scaffolding 7. Full house scaffolding 8. Suspended scaffolding 9. Attachment lift scaffolding 10. High operating basket 11. Foundation Pit Engineering. Template holder 13. High work 14. Construction electricity 15. Material hoist 16. Construction lift 17. Tower crane 18. Lifting hoisting. Construction equipment

- Q:Color steel sandwich board on the price of how much?

- Surface leveling should be able to, but the words come back, multilayer is cheaper than the former! For more information, better advice, free of charge to provide concrete waterproof water leakage II Cao Hao 丨 sell Zhatai Chunjun repair professional and technical advice, from today's repair, tomorrow leak;

- Q:The general company to re-change the new version, the replacement is very troublesome. Our company's exterior wall decoration board convenient installation, thermal insulation, waterproof moisture, noise reduction noise are interested can consult. Polyurethane sandwich panels for the application of polyurethane sandwich panels

- This is hard to say, depends on your house shape, height, height, regular rectangle of the province, the polygon will be more.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Firepoof Rockwool Sandwich Panel with CMAX Logo

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords