Mechanical Steel Slab Billet Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

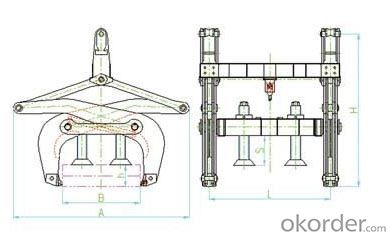

The billet clamp adopts the lever principle, without external force, flexible, safe and reliable lifting. Lifting device USES the high strength and high wear resistant alloy steel manufacturing, long service life. The structure of the billet hanging clamp fixed and adjustable stepless adjustable height, to adapt to the different specifications and different layers of lifting billet. The connection forms of crown with customers according to actual design.

Billet clamp is mainly composed of hanging beam, connecting rod, opening and closing mechanism, synchronizer, clamp arm, support plate and jaws of seven parts.

Hanging beam

Hanging beam is connected with day coupling components, has rings shackle type connection, sling type connector and lug type three kinds of structure. Rings hanging shackle type connection shaft, make the force of the spreader to improve, but also avoids the decoupling phenomenon when loading and unloading of steel billet, reducing the height of the jig itself, is conducive to use low places. Sling hoisting shaft type connection, make the stress of the jig is better, but the height of the sling itself is big, need to be used in the high places, for hanging hook used artificial auxiliary. Lifting lug type connection shaft, can directly by the crane operator, but need to make the sling when hoisting operation, and lower the hook until no stress, so easily lead to decouple the crane hook.

Connecting rod

The connecting rod is a lifting beam and clamp arm of the fittings.

Opening and closing mechanism

Manual lifting lever type opening and closing mechanism, double hook type (to be automatic), (automatic) single hook type, and form, such as type (automatic) the lock. Automatic opening and closing mechanism does not need any external power supply, the gravity of the jig itself automatically open and close. Close the lubrication mechanism: should add lubricating oil regularly (2 ~ 3 days) (or oil), lubrication. Forbidden to add too much grease!

Synchronizer

Synchronizer is guaranteeing each clamp fixture arm synchronous movement of the device.

Clamp arm

Clamp arm is the main power of the fixture components, the billet pick up through it

Support plate

The plate is support of billet clamp. Plate is supported on the billet surface to ensure the open-close mechanism of billet clamp smooth action

Jaws

Jaws have pin connection type; dovetail connection type and tank type plug type structure, etc. Jaws are the main parts; direct contact with steel billet determines the reliability of billet clamp clamping steel billet

Features:

Flexible, safe and reliable lifting

High strength and high wear resistant alloy steel manufacturing

Can be adapted to the different specifications and different layers of lifting billet

Technical Data:

Rated load ( t ) | Application (mm) | Basic leg high (mm) | Span (mm) | Max. size (mm) | |

W | H | ||||

5 | 250 | 800 | 1200 | 1800 | |

5 | 650-1000 | 250 | 800 | 1500 | 2300 |

8 | 150-450 | 250 | 1200 | 2000 | 2400 |

8 | 450-600 | 250 | 1200 | 1600 | 2500 |

- Q:What is equipment manufacturing and machinery manufacturing? What's the difference between them?

- Major technical equipment refers to the technical difficulty in equipment manufacturing, complete and strong, is of great significance, has a significant impact on the national economy need to be beneficial to the people's livelihood, complete sets of major technical equipment organizations across sectors, industries and regions to complete.

- Q:What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q:China mechanical net

- From Chinese GM parts, general machinery, hardware, tools, instruments, electrical appliances and related equipment, textile equipment, chemical equipment, agriculture, food equipment, construction equipment, environmental protection equipment, mining equipment, metallurgical equipment, financial equipment, commercial vehicles and accessories, machinery processing equipment, machinery processing industry machinery enterprises and mechanical products

- Q:What are the sub projects of a construction project?

- Appendix B Construction Engineering Division (sub branch) engineering, sub project division, B.0.1 Construction Engineering Division (sub branch), engineering, sub projects can be divided into table B.0.1. Table B.0.1 division number of construction works, sub works and sub projects

- Q:Construction machinery production need to deal with what documents?

- At all levels of production safety responsibility system, mainly refers to: the legal representative of the safe production responsibility system; the responsible person in charge of safety production safety responsibility system; the technical director (Chief Engineer) production safety responsibility system; the safety department (Department) Changan production responsibility system; responsibility for production safety, the project manager; specifically (and) post safety responsibility system for production safety; construction technician (technician), safety production responsibility system; 8 class (Group) Changan production responsibility system; workers, production safety responsibility system. Departments responsible for production safety system, mainly in accordance with the functions of enterprises set up departments, the corresponding formulation of the responsibility system for safety in production.

- Q:What are the main functions of construction equipment monitoring system?

- This belongs to information management engineering. The control part is the "heart" and "brain" of the whole system. It is the command center to realize the function of the whole system. The control part is mainly composed of the main console (some systems also have a secondary console). The main function of the total console: video signal amplification and signal distribution, image correction and compensation, image signal and image signal (including switching or voice signals) record, cameras and auxiliary components (such as camera, PTZ, shield) control (remote control) and so on.

- Q:How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q:What functions should be achieved in mechanical structure design?

- The design of mechanical structure is based on the overall design, according to the principle of the program to determine and draw a specific structure, in order to reflect the required functions. Is the working principle of the abstract concrete into some parts, the specific content in determining the structure of the material, shape, size, tolerance, heat treatment and surface conditions at the same time, we must consider the process, strength, stiffness, accuracy, and other parts of the relationship between each other and other issues. So, the direct product structure design is the technical drawings, but the design work is not a simple mechanical drawing, drawing only express design language, specific integrated technology is the basic content of structural design.

- Q:What are the sectors of machine building and parts processing?

- 3., machinery manufacturing is also a kind of industry, many industries have parts manufacturing, processing links. Therefore, the processing of parts does not belong to a particular industry.

- Q:Definition of large mechanical equipment?

- A crane is a machine that cycles and intermittently moves. A work cycle includes fetching device from the extract to bring up the product, then move to the designated place down items, then reverse movement, the fetching device back in, for the next cycle.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mechanical Steel Slab Billet Clamp

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords