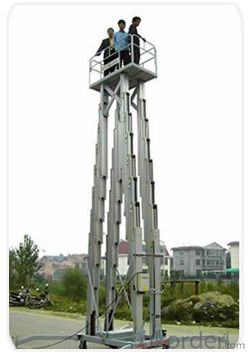

Mast type Aerial Working Platform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Single/double-mast aluminum alloy lifts are classified into four kinds on different lifting height: 4m, 6m, 8m, 9m etc. this model of lift are mainly made of high-duty aluminum alloy structure, so the total dimension of machine is very small and low weight and operated easily and conveniently.

Application

With these characters, single-mast aluminum alloy lift can be carried into narrow spaces passing through doors, stairs, and elevators.

Aluminum alloy lift is suit for hotels, banks, big halls, supermarkets, airport waiting rooms, and railway station waiting rooms etc.

Features:

The safety set of hydraulic pipeline rupture explosive-proof device;

The leakage protection device;

High strength aluminum alloy for lifting mechanism;

Overload safety device;

Emergency drop device;

Low weight and operated easily.

Technical Data:

Model | Capacity | Table size | Work height | Max height | Total dimension | Net weight |

SHJ0.1-4 | 100kg | 650*650mm | 3.5m | 4.5m | 1200*900*1980mm | 350kg |

SHJ0.1-6 | 100kg | 650*650mm | 5.5m | 7.5m | 1200*900*1980mm | 420kg |

SHJ0.1-8 | 100kg | 650*650mm | 7.5m | 9.5m | 1200*920*1980mm | 480kg |

SHJ0.15-8 | 150kg | 1470*800mm | 8m | 9.7m | 2000*1200*2300mm | 500kg |

SHJ0.15-10 | 150kg | 1470*800mm | 10m | 11.7m | 2100*1400*2400mm | 600kg |

SHJ0.15-12 | 150kg | 1470*800mm | 12m | 13.7m | 2100*1400*2700mm | 700kg |

SHJ0.1-14 | 100kg | 1470*800mm | 14m | 15.5m | 2100*1400*2800mm | 800kg |

- Q:What does the crane model qd25/5-16.5 A5 mean

- 16.5 refers to a crane span of 16.5 m, A5 is a working level A5, and is not frequently used frequently.

- Q:The crane truck walked in a wrong way

- Measures to prevent the wheel gnawing It is possible to prevent the wheel gnawing by limiting the ratio between the span of the single beam crane bridge and the ratio between the wheelbase. Can also be used between the orbits of the wheel rim and the corresponding coupled with lubricating oil, which can effectively reduce the whole operation of the friction, and finally reduce the wheel wear, and so on to prevent wheel gnawing rail; In addition, anhui crane machinery co., LTD. Is a more direct method to check the relevant equipment in time.

- Q:What does the working grade A1A8 mean

- Load condition of crane The load state of the crane is related to two factors, one is the actual lifting load and the maximum payload ratio (Pi/Pmax) The other one is the number of lifting loads associated with the total work cycle ratio (ni/N). The value of Pi/Pmax and ni/N is called Kp, and the expression is: KP = Pi - I = 1 lift load, I = 1, 2, 3... N; Ni -- the number of effects of load Pi; N -- the total number of work cycles. Pmax - rated weight; M -- exponential; Table 3 is the load state of the crane and its nominal load genealogy table. Table 3 crane load condition and nominal load spectral coefficient Kp The nominal load factor, KP says Q1 - light In Q2 - Q3 - heavy Q4 - heavy 0.125 0.25 0.5 1.1.0 is seldom raised with a nominal load Sometimes the load is rated, and the average lift is moderate The load is usually raised, usually lifting heavy loads The load is rated frequently Crane working grade The crane is divided into eight working levels according to the crane utilization level (table 2) and load condition (table 3) A1 ~ A8. Table 4 is a breakdown table of the working level of the crane.

- Q:What is the crane walk?

- The crane runs the route from the rails, which ensures that the crane runs along the specified line and delivers the wheel pressure to the base.The orbit is usually composed of two rails, which carry heavy loads, such as the track of a large cable crane, which consists of several rails.According to the purpose and type of crane, can use ordinary railway rail, crane rail (see figure] [crane rail) or square and rectangular cross section of rail.Special compared with the ordinary railway rail, crane rail head width, height, rail waist, is conducive to improve contact with wheels, and conducive to under horizontal load, but the price is more expensive.The cranes that run on the ground are mainly made of ordinary railway rails;The bridge crane is commonly used for steel rail and other rails.There is a similar type of track in the crane, which is fixed in the bridge of the crane or the horizontal arm, and the flange of the girder is the track of the car.The base of the crane track is concrete, reinforced concrete, road slag sleeper and metal girder.The rail joint should ensure that the crane runs smoothly and reduces the impact.Track the laymen, gauge and the high and low two rail has a great influence on the running performance of crane, must according to the specification requirements of accuracy for installation.The rails should be fixed in case the foundation slides.The track may be deformed in the course of the process, and the steel rail head is liable to wear out, so it is possible to make the connection between the track and the foundation so as to adjust the replacement.

- Q:The tower crane command gesture

- Stop: the forearm level is placed on the chest, the fingers stretch, palms facing down, the horizontal wave to the side. Emergency stop: two small arms horizontal to the chest, five fingers outstretched, palms facing down, while horizontal wave to the side. End of work: open your hands with fingers and cross in front of your forehead.

- Q:The principle of magnetic cranes helps

- There is a magnetic field in the magnet. When the metal is adsorbed it will also be magnetized and magnetic and magnetic field, and its magnetic field lines are in the same direction as permanent magnets. According to this principle, we can move another magnet near it, and make their magnetic field go in the opposite direction of repulsion, thus leaving the metal out.

- Q:Compared to the hook crane, the advantages and disadvantages of the electromagnetic crane

- Advantages; 1, you don't need to be able to get a hook for the lifting and landing, and you can screen for objects that need to be hoisted (such as steel).

- Q:Where do you need a crane

- Logistics loading and unloading, the construction of tunnel engineering, railway track laying and maintenance, oil, chemical, electric power, water, steel, exploration, metering, garden, wharf, ships, municipal maintenance, fire-fighting equipment, national defense construction and other fields.

- Q:Details of several anti-rolling systems of the tyrotype container gantry crane?

- 4 hoisting wire rope cross winding way 4 1 institution arrangement and working principle of the four hoisting rope pulley, directly from the drum to sling the shelves on the pulley cross winding (different from normal winding). Then the transition from the car frame and the steering pulley back to the hoisting mechanism. This arrangement fully consider the car frame pulley offshoring lifting point as far as possible, in order to realize the hoisting wire rope in the direction of the horizontal component of the car is enough big, depends on this component to achieve the function of spreader in the car direction stabilizer. When the lifting gear starts to swing, the horizontal component of the other side of the raised wire will hold down the swing of the harness. The anti-rolling effect of this arrangement is obvious. The pulley of the wire rope is small, four rising wire rope length is consistent, the winding form is unified, can reduce the difficulty of maintaining the work. Simplifies the car arrangement, the car on the shelf arrangement organization completely symmetrical, avoid the happening of the partial load in traditional design, make the stress of the structure form more hasten is reasonable.

- Q:What should the crane driver do when the accident occurred

- A first put suspended objects in a safe place, the second is the crane stopped electricity, 3 it is report to superior, four is cooperate to rescue the injured, five is to protect the scene.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Mast type Aerial Working Platform

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords