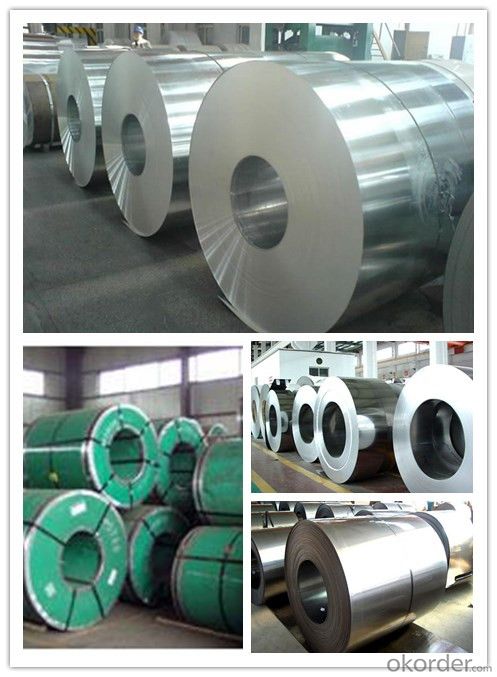

Prime Cold Rolled Carbon Steel Coils with SPCC-SD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Basic description .

Model NO.:SPCC SPCD SPCE ST12-15 DC01-06

Surface Treatment:Coated

Certification:ISO

Technique:Cold Rolled

Standard:ASTM, JIS, GB, DIN, BS

Application:Boiler Plate

Edge:Slit edge

Stock:Stock

Steel Grade:SPCC SPHC

Certificate:ISO 9001-2008, SGS, CE, BV

Width:600-2000mm

Thickness:0.11-3.0mm

Inside Diamete:508mm or 610mm

Delivery Time:10-15days After Receipting The Advance Payment

Export Markets:South America, Eastern Europe, Southeast Asia, Oceania, Mid East, Eastern Asia, Western Europe

Additional Info.

Trademark:Sino Steel-Cold Rolled Carbon Steel Coil

Packing:Standard Export Package

Standard:SGS, CIQ, BV, ISO, CE

Origin:China

HS Code:72091790

Production Capacity:10000tons/Month

Product Description

Cold Rolled Carbon Steel Coil:

Products Detail:

Thickness:0.11-3mm

Width:600-2000mm

Length:as your need

Standard:AISI, ASTM, BS, DIN, GB, JIS

Grade;SPCC/SPCD/SPCE/ST12-15/DC01-06.

Delivery time:15-20days after receipting the advance payment.

Package: Standard export packing or as your requested.

Technique:

Surface Treatmentunoil,dry,chromate passivated, non-chromate passivated

Application:Widely used in ships, automobiles, bridges, buildings, machinery, etc

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

>

- Q:Can steel coils be used in structural applications?

- Yes, steel coils can be used in structural applications. They are often used in the construction industry for various structural components such as beams, columns, and trusses. Steel coils provide strength, durability, and flexibility, making them suitable for supporting heavy loads and withstanding various environmental conditions.

- Q:How are steel coils used in the manufacturing of storage racks?

- Steel coils are used in the manufacturing of storage racks by being cut and formed into structural components, such as beams and columns, which provide the necessary strength and durability to support the weight of stored items. These coils are processed through various machines and techniques, including bending, welding, and painting, to create the final storage rack structures.

- Q:How do we use steel ?plesase answer, its for homework xxx

- This Site Might Help You. RE: How do we use steel ? How do we use steel ? plesase answer, its for homework xxx

- Q:All of my friends say that if a car made of mostly carbon fiber would crash into a full steel car, or vice versa, the steel car would be DESTROYED and the carbon fiber would drive away, if not, easily repairable.

- At a reasonably high speed, both cars would be undrivable. That's by design, not due to the strength/weakness of the materials. The energy in an impact needs to go somewhere. Cars are designed so the body and the frame will bend and break, reducing the impact on the occupants. If the car is too rigid the chances of the occupants being injured increases. Carbon fiber composites do have a better strength to weight ratio than steel but they're also a lot less dense, so the same volume of material will have a similar strength. The primary benefit to carbon fiber is that for a part of the same strength the carbon fiber part will weigh less than the steel part.

- Q:What is the purpose of coating steel coils?

- The purpose of coating steel coils is to provide a protective layer that prevents corrosion and enhances the durability and lifespan of the steel.

- Q:What is the maximum width of galvanized steel strip, please? The galvanized coat is 275, and how long is one coil?

- As far as I know, the galvanized rolls of WISCO are wider in width than other domestic steel mills, and can produce 2080 wide steel coils.

- Q:How are steel coils used in the manufacturing of industrial compressors?

- Steel coils are used in the manufacturing of industrial compressors as a crucial component for constructing the compressor's internal structure, such as the casing and housing. The steel coils provide strength, durability, and stability to the compressor, allowing it to withstand high pressure and temperature conditions. Additionally, the coils are often used in the construction of the compressor's motor, providing support and ensuring efficient operation. Overall, steel coils play a vital role in the manufacturing of industrial compressors by providing the necessary structural integrity and functionality.

- Q:Many gerber knives are made out of what gerber calls high Carbon steels and I was wondering if anyone knew exactly what is this mysterious steel.

- The carbon content of the knife is done during the smelting process.For instance a knife that has a high carbon content will keep an edge much longer than one with a lower content. It is tricky because too much will cause the knife to be brittle and break easily. Annealing is also part of the process of knife making.

- Q:is a 1962 steel penny worth anything?

- 1962 D Penny

- Q:How are steel coils processed and shaped into various products?

- Steel coils are processed and shaped into various products through a series of manufacturing processes. First, the steel coil is uncoiled and cleaned to remove any impurities. Then, it goes through a process called leveling, where the coil is flattened and straightened. Next, the steel is cut into the desired length or shape, using techniques like shearing or slitting. After that, it may undergo additional processes such as forming, bending, or rolling to give it the desired shape. Finally, the steel is often treated with coatings or finishes to enhance its durability and appearance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Prime Cold Rolled Carbon Steel Coils with SPCC-SD

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords