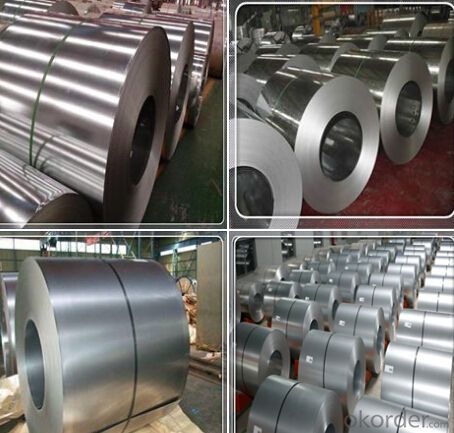

High Quality Stainless Steel Coils (201)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Model NO.:201

Type:Stainless Steel Sheets

Certification:SGS

Standard:ASTM, AISI, JIS

Technique:Cold Rolled

Surface Treatment:Polished

Export Markets:Global

Additional Info.

Trademark:CWG

Packing:Seaworthy Packing

Standard:ASTM, JIS, EN, GB, KS, DIN

Origin:China

HS Code:72193300

Product Description

Stainless Steel Sheet (201,202)(Cold Rolled)

We main supply stainless steel sheet/plate every year, For the 304 stainless steel

Sheet, we have the NO. 1 2B BA NO. 8 HL surface and so on. For the cold rolled 304

Stainless steel plate, the thickness we have: 0.3mm, 0.4mm, 0.5mm, 0.6mm, 0.7mm, 0.8mm,

0.9mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm. For the hot rolled 304 stainless steel

Plate, the thickness we have: 3.0mm, 4.0mm, 5.0mm, 6.0mm, 8.0mm, 10.0mm, 12.0mm, 14.0mm,

16.00mm, 20.00mm and so on. For these thickness above, all the 304 stainless steel plate

We arrange directly from big factories such as: TISCO, JISCO, BISCO, KSK, KRUPP. For the

Thickness above 20.00mm, we can manufacture for you, the max thickness of 304 stainless

Steel plate we can produce for you is 100.00mm.

Type Stainless steel plate /sheet.

Thickness 0.3 mm-80mm

Width 1000mm, 1219mm, 1240mm, 1500mm, 1800mm, 2000mm

Length 2000mm-6000mmor as customer request

Standard ASME, ASTM, EN, BS, GB, DIN, JIS, etc

Material 201, 202, 301, 321, 304, 304L, 316, 316L, 309S, 310S, 410, 410S, etc

Surface 2B, BA, 8K, No. 4

Brand name TISCO, BG, ZPSS, YUSCO, JISCO, BXIN, KSK, KRUPP

Packaging Standard export sea-worthy packing

Technique Hot rolled / cold rolled

Delivery time 10-30 days

Supply ability 500 metric tons/ month

Payment terms L/C, T/T

Application range Foodstuff, gas, metallurgy, biology, electron, chemical, petroleum,

Boiler, nuclear energy Medical equipment, fertilizer, etc.

Note We can produce other standard as the customers' requirement.

FAQ

1.What's your MOQ?

25MT, it is for one container.

2.Do you have QC teams?

Yeah, sure, our QC team is very important, they will keep the quality control for our products.

3. What's your normal delivery time?

Our delivery time about 10-20days for standard sizes, if you have other requirements like hardness and width ,it is about 20-40days. But don't worry ,we also try our best for the delivery time ,because time longer and our cost is higher.

4.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q:How are steel coils used in the manufacturing of automotive springs?

- Steel coils are used in the manufacturing of automotive springs as they provide strength, durability, and flexibility required for suspension systems. The steel coils are shaped and formed into the desired spring shape, ensuring optimal performance and handling of the vehicle.

- Q:What are the different steel coil finishes available?

- There are several different steel coil finishes available, including hot rolled, cold rolled, galvanized, and coated finishes.

- Q:What are the different steel coil packaging methods?

- There are several different steel coil packaging methods, including using steel strapping or banding to secure the coils, using plastic or metal end caps to protect the edges of the coils, and using wooden or steel pallets to stack and transport the coils. Additionally, some steel coils may be wrapped in protective film or paper to prevent damage during shipping and storage.

- Q:Can steel coils be coated with anti-fingerprint materials?

- Yes, steel coils can be coated with anti-fingerprint materials. These materials are designed to reduce the visibility of fingerprints and smudges on the surface of the steel, providing a cleaner and more aesthetically pleasing appearance.

- Q:How do steel coil manufacturers ensure timely delivery?

- Steel coil manufacturers ensure timely delivery by implementing efficient production and supply chain management systems. They closely monitor the production process, maintain a well-planned inventory, and coordinate with logistics partners for streamlined transportation. Additionally, they prioritize effective communication with customers to understand their delivery requirements and provide regular updates on the progress and estimated delivery dates.

- Q:How are steel coils used in the production of medical equipment?

- Steel coils are used in the production of medical equipment in a variety of ways. One common use is in the manufacturing of surgical instruments. Many surgical instruments, such as scalpels, forceps, and clamps, require a sharp and durable cutting edge. Steel coils are used to create these cutting edges, as they can be easily shaped, hardened, and sharpened to ensure precision and longevity. Additionally, steel coils are often used in the production of medical devices such as braces, orthopedic implants, and prosthetics. These devices require materials with high strength and durability to support and stabilize the body. Steel coils can be formed into different shapes and sizes to meet the specific needs of patients, providing the necessary support and functionality. Furthermore, steel coils are used in the production of medical equipment such as MRI machines and X-ray systems. These machines require strong and reliable components to ensure accurate imaging and diagnostics. Steel coils are used in the construction of these machines to provide stability and structural support, allowing for precise and high-quality imaging. In summary, steel coils play a crucial role in the production of medical equipment by providing strength, durability, and versatility. From surgical instruments to orthopedic devices and diagnostic machines, steel coils are utilized to create reliable and high-performing medical equipment that ultimately improves patient care and outcomes.

- Q:what is the difference between metal and steel

- well, steel is a type of metal. It's sort of like asking the difference between a bug and an ant, an ant is a bug, but not every bug is an ant. Likewise, steel is metal, but not all metal is steel. Gold is metal, Silver is metal, Iron is metal, Steel is metal.

- Q:Can steel coils be coated with anti-corrosive substances?

- Yes, steel coils can be coated with anti-corrosive substances such as zinc, paint, or polymer coatings to protect them from rust and corrosion. These coatings act as a barrier between the steel surface and the surrounding environment, preventing contact with moisture and corrosive elements.

- Q:Heard some steel companies like TATA Steel and JSW are in good performance. can some one suggest me if its good time to invest in steel industry ?

- I feel metal stocks can give some return now if you invest.

- Q:What is the average thickness tolerance for steel coils?

- The average thickness tolerance for steel coils can vary depending on the specific industry and application. However, a common tolerance range for steel coils is typically around +/- 0.005 to 0.01 inches.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Stainless Steel Coils (201)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords