CMAX Double Steps TypePP /PE Thin Film & PP Woven Bag Recycling Pelletizing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Item: PP PE thin film and PP woven bag plastic recycling pelletizing machines

1. Our advantages

We are plastic machinery manufacturer and can provide you machines at competitive price.

Our Machines are worthy of trust, for we have been in this field for over 10 years and our machines are CE certified.

Our company is not far away from Shanghai, which is convenient for us to deliver machines.

2. Application

Our PP PE thin film and PP woven bag plastic recycling pelletizing machines is an ideal equipment for recycling plastic film, bag, bit, belt, sheet or others (thickness below 0.5mm) such as pp pe

3. Features

This PP PE thin film and PP woven bag plastic recycling pelletizing machines is one of our hot sale products with the following features.

Safe in Operation------CE certified

High Quality and Durable------Materials are selected with care

Good Performance and Hot Sale------Low niose, low power consumption, high output and easy to operate

4. Configration and Parameter

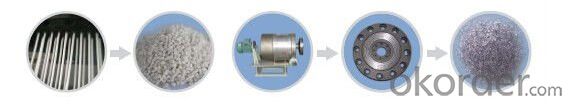

This PP PE thin film and PP woven bag plastic recycling pelletizing machines consists of belt conveyor, agglomerator, single screw extruder, degassing system, screen changer, die, die-cutting & dewatering system and air blower & silo unit.

Technical paramete

Model | Screw dia.(mm) | Motor Power (Kw) | L/D | Sub machine Model | Screw dia.(mm) | Motor power (kw) | L/D | Output | |

CAMX-100 | 100 | 55-75 | 34/1 | CAMX-100 | 100 | 22-30 | 9/1 | >=100 | |

CAMX-120 | 120 | 75-132 | 34/1 | CAMX-120 | 120 | 37-45 | 9/1 | >=250 | |

CAMX-150 | 150 | 110-160 | 34/1 | CAMX-150 | 150 | 45-75 | 9/1 | >=400 | |

CAMX-200 | 200 | 160-250 | 34/1 | CAMX-200 | 200 | 55-110 | 9/1 | >=600 |

Double Steps Type PP/PE Thin Film And PP Woven Bag Recycling Pelletizing Machine

This film recycling and pelletizing machine composed by two extruders, is good for recycling the raw materials which have much moisture such as film, foamed materials. The double-vent system increases the degasification volume. And the force feeding system ensures the higher production capacity.

Our Services

The Photo of Double Steps Type PP/PE Thin Film And PP Woven Bag Recycling Pelletizing Machine

Packaging & Shipping

- Q:Waste plastics granulation EIA Report Sample

- The book is very thick and the EIA form is very simpleYou directly find qualified to do the EIA, for you to doAre you planning to apply for the quota for imported plastic waste?

- Q:How about the granulator?

- In the development of drying equipment, research and innovation and innovation, a series of advanced and energy-saving products are designed and manufactured. It has developed more than 40 kinds of drying, granulating, mixing, dust series according to the needs of the market, the drying products are widely used in pharmaceutical, chemical, food, light industry and other industrial raw materials or products, praised by users. Customer acceptance test and inspection are welcome.

- Q:How is the feeding instability of the single screw plastic granulator?

- It depends on what kind of machine you are. What kind of material will be used and the temperature at the inlet should not be too high. Is it a regular granulator?.

- Q:Is environmental protection approved for plastic granulation?

- A project does not require EIA, and the EIA is a report or a report form, according to the State Environmental Protection Department's "construction project environmental impact assessment classified management list" of the coming.According to the provisions of the "construction project environmental impact assessment classification management directory", plastic products manufacturing in artificial leather, foam rubber involving toxic materials; a plating process requires the preparation of the EIA report; the rest of the need for the preparation of the EIA report table.

- Q:May I ask who knows the plastic granulator manufacturers contact ~ figure

- China is the same, who knows who ah?. Otherwise, better contact

- Q:How much will it cost to invest in the recycled plastic particle production line?

- 4. more efficient cutting and compacting machine to ensure high output of granulator equipment and low energy consumption.5., from Europe's leading design of dehydration machines and vibrating screen, greatly reducing the energy consumption of equipment,And improve the efficiency of granulator equipment.6., the new granulator has: reasonable configuration, smooth operation, low noise, energy saving, high yield and so on7. certification of CE and ISO9001 professional organizations.

- Q:How can the granulator recycle the plastic bottle?

- Well, what is the sorting process of the plastic granulator?A typical process in which the discarded bottles will be sorted first on the basis of color and size sometimes. Once sorted, they need to be washed away; however, the washing machine, while in a piece, is not the most advantageous way. Therefore, to facilitate the washing process, the bottle is likely to be broken down into small pieces. Plastic granulator, plastic grinding machine can be used to do work, such as Jordan to reduce the manufacture of solutions. They let a shredder break down into smaller sizes and then send it to the cleaning station for a wide variety of plastic and PET containers. Check out some plastic crush videos. Once the bottle is torn and a suitable size is washed, they are not yet ready for processing into other goods.

- Q:What plastic particles are used for wire injection? How much would you like to invest in a plastic pelleting plant?

- Plastic granulation plant can also be large, small, small, about 100000, about 200000 of the general, large, millions of normal.

- Q:Comparison of swing granulator, high-speed granulator, one-step granulator difference?

- The so-called wet granulation is generally back to the use of materials, granulation is not afraid of a little moisture exists.

- Q:Plastic granulator feed roller does not turn is what reason

- You see whether the gear or chain is driven, if it is a positive gear or the chain is broken. There is also a two axis of its own teeth rotation, it may be broken bearings.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

CMAX Double Steps TypePP /PE Thin Film & PP Woven Bag Recycling Pelletizing Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 15 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords