PVDF Coated Aluminum Coils 3003 H16 with High Quality Used for Aluminum Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

1. Structure of PVDF Coated Aluminum Coils 3003 H16 with High Quality Used for Aluminum Composite Panels

Color coated aluminum coils are widely used for aluminum composite panels. We normally use alloy 3003 and temper H16.

We have different colors for aluminum composite panels. RAL numbers are no problem for us. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of PVDF Coated Aluminum Coils 3003 H16 with High Quality Used for Aluminum Composite Panels

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

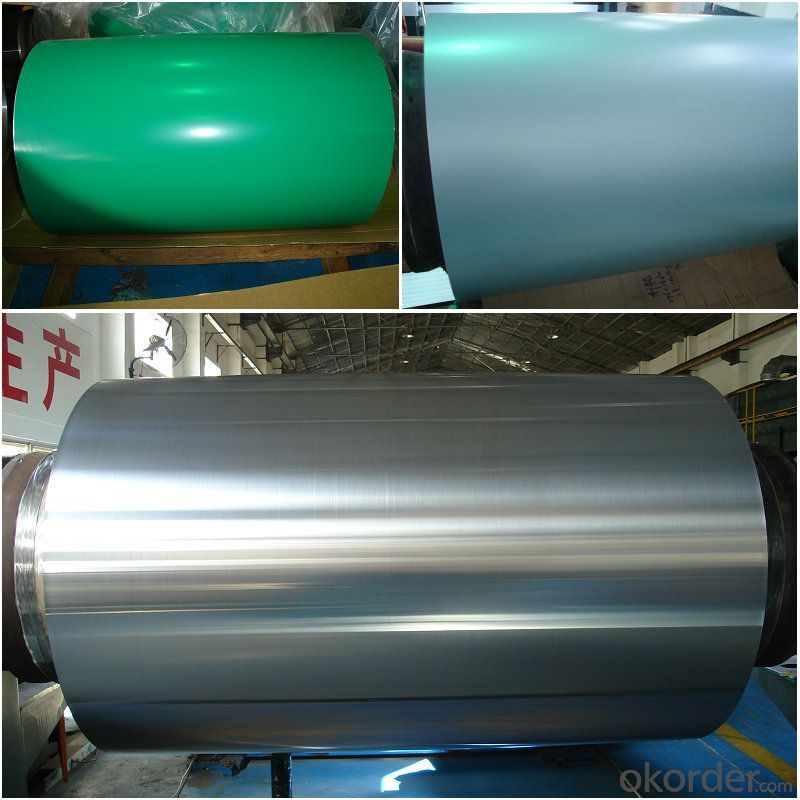

3. PVDF Coated Aluminum Coils 3003 H16 with High Quality Used for Aluminum Composite Panels Images

4. Specification of PVDF Coated Aluminum Coils 3003 H16 with High Quality Used for Aluminum Composite Panels

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q:Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers a wide range of benefits for interior design projects. Firstly, aluminum is lightweight, making it easy to handle and install. This is especially advantageous for projects that require large-scale installations or suspended ceilings. Additionally, aluminum coils are highly durable and resistant to corrosion, ensuring their longevity and making them suitable for high-traffic areas. Furthermore, aluminum can be easily customized and shaped to meet specific design requirements, allowing for endless design possibilities. The material is also available in a variety of finishes, such as brushed, polished, or anodized, which can enhance the aesthetic appeal of any interior space. Moreover, aluminum is a sustainable and eco-friendly option, as it is easily recyclable and has a low carbon footprint compared to other materials. Overall, aluminum coils are a practical and aesthetically pleasing choice for interior design applications.

- Q:How do aluminum coils perform under high-temperature applications?

- Aluminum coils are known for their excellent heat resistance and performance in high-temperature applications. Due to their low melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), aluminum coils can withstand and operate efficiently under elevated temperatures. Aluminum has a high thermal conductivity, meaning it can quickly transfer heat away from the coil, preventing overheating and potential damage. This property allows aluminum coils to effectively dissipate heat, resulting in improved thermal management and enhanced performance in high-temperature environments. Moreover, aluminum coils exhibit good corrosion resistance, which is crucial in applications where heat and moisture are present. The oxide layer that naturally forms on the surface of aluminum provides a protective barrier against corrosion, ensuring the longevity and reliability of the coil even in challenging conditions. Furthermore, aluminum coils are lightweight and possess excellent formability, allowing for easy installation and integration into various systems and applications. This versatility makes them suitable for a wide range of high-temperature applications, including heat exchangers, automotive components, HVAC systems, and electrical devices. However, it is important to note that extreme temperatures beyond the melting point of aluminum can cause the material to weaken or deform. Therefore, it is essential to consider the specific temperature requirements and limitations of the aluminum coil before implementing it in a high-temperature application.

- Q:I was told today that taking aluminium inside your body greatly increases the chance of getting alzheimers as they destroy cells. What foods contain aluminium?

- challenging task. do a search over bing and yahoo. that will might help!

- Q:Are aluminum coils resistant to corrosion?

- Yes, aluminum coils are resistant to corrosion. Aluminum has a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This oxide layer forms when aluminum is exposed to oxygen in the air. It prevents the metal from coming into direct contact with moisture or other corrosive elements. Additionally, aluminum coils can be further protected through various coating or finishing processes, such as anodizing or painting. These additional layers provide an extra level of protection against corrosion, making aluminum coils highly resistant to rust and other forms of deterioration.

- Q:Why the aluminum sheet crack after?

- It is either because of wrong filling material for welding or bad welding quality. It doesn’t crack after welding, but cracks when the increasing tension in circling process exceeds the internal stress of the weld.

- Q:Can aluminum coils be used in building facades?

- Yes, aluminum coils can be used in building facades. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for exterior applications. Its flexibility allows for various design options, and its low maintenance requirements make it a popular choice for building facades.

- Q:Are aluminum coils suitable for HVAC systems?

- Yes, aluminum coils are suitable for HVAC systems. Aluminum coils offer several advantages over traditional copper coils. They are more resistant to corrosion, which helps in increasing the lifespan of the HVAC system. Aluminum coils also have better heat transfer properties, allowing for more efficient cooling and heating. Additionally, aluminum coils are lighter in weight, making them easier to install and handle during maintenance or repairs. Overall, aluminum coils are a reliable and cost-effective option for HVAC systems.

- Q:The heat of fusion of aluminum is 3.95kj/g. What is the molar heat of fusion of aluminum? What quantity of energy is needed to melt 10.0g of aluminum? What quantity of energy is required to melt 10.0 mol of aluminum? Three questions i need help with can someone show me step by step please so i can get it thank you a bunch

- This Site Might Help You. RE: heat of fusion of aluminum? The heat of fusion of aluminum is 3.95kj/g. What is the molar heat of fusion of aluminum? What quantity of energy is needed to melt 10.0g of aluminum? What quantity of energy is required to melt 10.0 mol of aluminum? Three questions i need help with can someone show me step by step please so i can...

- Q:Can aluminum coils be used in solar panel installations?

- Yes, aluminum coils can be used in solar panel installations. Aluminum is a popular choice for the construction of solar panels due to its lightweight nature, corrosion resistance, and excellent thermal conductivity. Aluminum coils are often used as the backing material for solar panels, providing structural support and heat dissipation. They are also commonly used in the manufacturing of solar mounting systems, which hold the panels securely in place. Overall, aluminum coils are a reliable and efficient option for solar panel installations.

- Q:What are the factors that affect the price of aluminum coils?

- There are several factors that can affect the price of aluminum coils. One of the primary factors is the global supply and demand for aluminum. If there is a shortage of aluminum, the price of aluminum coils is likely to increase. On the other hand, if there is an oversupply of aluminum, the price may decrease. Another factor that can impact the price of aluminum coils is the cost of raw materials. Aluminum is derived from bauxite, and the cost of mining and extracting bauxite can vary depending on factors such as labor costs, energy prices, and government regulations. Any changes in these factors can affect the overall cost of producing aluminum, which in turn can influence the price of aluminum coils. Transportation costs also play a role in determining the price of aluminum coils. Aluminum is often transported over long distances, and the cost of shipping or trucking can vary depending on fuel prices, distance, and other logistical factors. Higher transportation costs can add to the overall price of aluminum coils. Currency exchange rates can also impact the price of aluminum coils. Aluminum is traded on global markets, and changes in exchange rates can affect the cost of importing or exporting aluminum. If the currency in which aluminum is traded strengthens against other currencies, the price of aluminum coils may increase. Lastly, market competition can affect the price of aluminum coils. If there are multiple suppliers of aluminum coils, they may compete with each other to secure customers. This competition can lead to price fluctuations as suppliers try to attract buyers by offering competitive prices. In conclusion, the price of aluminum coils can be influenced by factors such as global supply and demand, the cost of raw materials, transportation costs, currency exchange rates, and market competition. Understanding these factors can help businesses and consumers anticipate and respond to changes in the price of aluminum coils.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVDF Coated Aluminum Coils 3003 H16 with High Quality Used for Aluminum Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords