Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering high quality Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg is mainly used in forest region, mines, factories and construction sites laid of the place such as temporary transport line and light motorcycles with line. Be widely used for railway, subway, transportation track, express, curve way, tunnel way and so on.

Product Advantages:

OKorder's Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

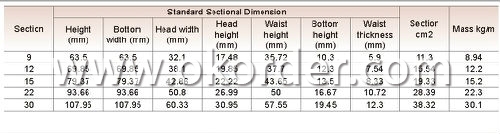

Product Specifications:

Specifications of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

Production Standard: GB 11264-89, DIN, AREMA, JIS, BS, UIC, etc.

Sizes: 9kg, 12kg, 15kg, 22kg, 30kg

Length: 6m-25m according to the requriements of the clients

Material: Q235B, 55Q, 900A, etc.

Alloy No | Grade | Element(%) | ||||

C | Mn | S | P | Si | ||

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 |

Invoicing on theoretical weight or actual weight as customer request

Payment terms: 30% advance payment by T/T, 70% payment against the copy of the B/L; 100% L/C at sight, etc.

Packaging & Delivery of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

6. Delivery Time: All the Hot Rolled Steel Rail will be transpoted at the port of Tianjin, China within 30 days after receiving the advance payment by T/T or the orginal L/C at sight.

Inspection of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

We will send the MTC of the factory to the clients dirrectly which contain the anlisis of the heat, chemiqul composition, phisical characteristicas, etc.

And our inspectors will arrive at the factory to meke the inspection of the size, length, weight and quantity before the transportation from the factory.

FAQ:

Q1: What is the normal tolerance of Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg?

A1: Normally 3%-5%, but we can also produce the goods according to the customers' requests.

Q2: Can fit in the containers of 20inches the Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg of 6M?

A2: No proble, we can put them into the containers in the form sideling.

Q3: The products are invoicing on theoritical weight or on actual weight?

A3: We can do it in both manners, according to the customers' request.

- Q:How are steel rails protected against track geometry irregularities?

- Steel rails are protected against track geometry irregularities through regular inspection and maintenance. This includes monitoring the alignment, elevation, and curvature of the tracks to ensure they meet the required standards. Any deviations or irregularities detected during inspections are promptly addressed through corrective measures such as realignment or resurfacing. Additionally, advanced technologies such as track geometry cars and laser scanning are employed to identify and rectify any potential issues before they escalate. These proactive measures help to maintain the integrity and safety of the rail infrastructure, ensuring smooth and reliable train operations.

- Q:How do steel rails handle different weather conditions?

- Steel rails are specifically designed to effectively handle various weather conditions. The exceptional properties of steel render it highly resistant to different weather elements. When faced with cold weather, steel rails are capable of enduring freezing temperatures without becoming brittle or developing cracks. This resilience can be attributed to the low thermal expansion coefficient of steel, which allows it to contract and expand without causing any damage. Additionally, steel rails possess a remarkable tensile strength, enabling them to bear heavy loads even in extremely cold conditions. Similarly, steel rails are well-suited to cope with high temperatures during hot weather. Due to its relatively high melting point, steel does not soften or compromise its structural integrity under normal operating conditions. Moreover, steel rails possess excellent heat dissipation properties, ensuring they cool down rapidly and maintain their strength. The resistance of steel rails to corrosion also makes them ideal for use in various weather conditions, including wet and humid environments. To enhance their corrosion resistance, the rails are often coated with protective layers, such as zinc or paint. This protective coating acts as a barrier, preventing moisture from reaching the steel surface and thereby inhibiting rusting, ultimately prolonging the lifespan of the rails. Furthermore, steel rails exhibit excellent traction properties, which are essential for safe train operations in different weather conditions. The design of the rail profile, coupled with the utilization of friction modifiers or anti-skid materials, guarantees that trains maintain adequate grip on the tracks, even during rainy or snowy weather. In conclusion, steel rails are meticulously engineered to withstand diverse weather conditions. They can endure extreme cold, high temperatures, moisture, and provide reliable traction for train operations. The durability, strength, and corrosion resistance of steel make it the preferred material for rail infrastructure, ensuring safe and efficient transportation in all weather conditions.

- Q:How are steel rails fastened to the sleepers?

- Steel rails are typically fastened to the sleepers using a combination of rail clips or fastenings, bolts, and baseplates. These components help secure the steel rails in place and provide stability and durability to the railway tracks.

- Q:How do steel rails handle expansion and contraction due to temperature changes?

- Steel rails are designed to handle expansion and contraction caused by temperature changes through the use of expansion joints and proper spacing between the rail tracks. This allows the rails to expand and contract freely without causing any significant damage or warping. Additionally, the steel material used in rails has a relatively low coefficient of thermal expansion, which helps to minimize the effects of temperature fluctuations.

- Q:What is the process of electrifying steel rails?

- The process of electrifying steel rails involves the installation and implementation of an overhead electric power supply system, commonly referred to as an overhead catenary system. This system comprises a series of wires, known as catenary wires, which are suspended above the tracks and connected to a power source. To commence the process, the existing infrastructure must undergo assessment to determine its suitability for electrification. This entails evaluating the condition of the rails, bridges, tunnels, and other structures along the rail line. If deemed necessary, upgrades or modifications may be necessary to ensure safety and compatibility with the electric system. Once the infrastructure is deemed suitable, the subsequent step involves the installation of the overhead catenary system. This entails the erection of support structures, such as poles or gantries, along the trackside to hold the catenary wires in place. These structures are strategically positioned to ensure proper tensioning and alignment of the wires above the tracks. Following the installation of the support structures, the catenary wires are put into place. These wires serve as conduits for the electric current that powers the trains. Typically, these wires are composed of a combination of copper and aluminum to provide both durability and conductivity. They are strung along the support structures, ensuring appropriate spacing and alignment to facilitate the safe movement of trains underneath. Once the catenary wires are installed, they are connected to a power source, which can be supplied from various sources, such as an electrical grid or dedicated power stations. Transformers and substations may be necessary to convert and distribute the power to the catenary wires. Upon connecting the power source, the electrification system undergoes testing to ensure proper functionality and safety. This includes conducting tests on the catenary wires, power distribution, and train operation. Any issues or deficiencies are addressed and resolved prior to the full operationalization of the system. Upon completion of all necessary tests and inspections, the steel rails are considered electrified and ready for use. Trains can now draw power from the catenary wires, thereby providing a more efficient and environmentally friendly mode of transportation. Regular inspections and maintenance are conducted to ensure the continued safe and efficient operation of the electrified rail system.

- Q:How are steel rails tested for strength and durability?

- Steel rails are tested for strength and durability through a rigorous process known as rail testing. This testing is conducted to ensure that the steel rails used in railway tracks meet the necessary standards and can withstand the heavy loads and daily wear and tear they are subjected to. One of the primary methods used to test steel rails is the ultrasonic testing method. This involves using high-frequency sound waves to inspect the internal structure of the rail. Ultrasonic waves are sent through the rail, and any disruptions or irregularities in the wave pattern indicate potential defects or weaknesses within the rail. This non-destructive testing method allows for a thorough examination of the steel rails without causing any damage. Another commonly employed testing technique is the hardness testing method. This involves measuring the hardness or resistance of the steel rail's surface to indentation. A specialized instrument known as a hardness tester is used to apply a controlled force on the rail's surface, and the depth of the indentation is measured. This measurement helps determine the rail's strength and resistance to deformation. Additionally, steel rails are subjected to visual inspections. This involves visually examining the rails for any signs of cracks, fractures, or other visible defects. Inspectors often use specialized equipment such as magnifying glasses, cameras, and even drones to ensure a thorough assessment of the rail's condition. To assess the durability of steel rails, accelerated fatigue tests are often conducted. These tests simulate the repetitive loading and unloading that the rails experience under normal operating conditions. The rails are subjected to cyclic loads, and the number of cycles required to cause failure or deformation is recorded. This information helps determine the rail's durability and expected lifespan. Furthermore, steel rails are tested for their resistance to corrosion, which can significantly impact their durability. Corrosion tests involve exposing the rails to various corrosive agents, such as saltwater or acidic solutions, and monitoring their reaction over time. These tests help evaluate the rail's ability to resist corrosion and maintain their structural integrity over prolonged periods. In conclusion, steel rails undergo a comprehensive testing process to ensure their strength and durability. Through techniques such as ultrasonic testing, hardness testing, visual inspections, fatigue tests, and corrosion tests, rail manufacturers and authorities can ensure that the steel rails used in railway tracks meet the necessary quality standards and can withstand the demanding conditions they are exposed to.

- Q:What are the safety measures for working on electrified steel rail tracks?

- When working on electrified steel rail tracks, some important safety measures include wearing appropriate personal protective equipment (PPE) such as insulated gloves and boots, maintaining a safe distance from live electrical lines, using insulated tools, and following proper lockout/tagout procedures to ensure that the power is turned off before any work is done on the tracks. It is also crucial to receive proper training on electrical safety and to regularly inspect and maintain the equipment and infrastructure to prevent accidents and electrical hazards.

- Q:Are steel rails used in freight train operations?

- Indeed, it is common practice for freight train operations to utilize steel rails. These rails offer a robust and sturdy track infrastructure capable of withstanding the substantial loads and constant utilization of freight trains. They possess the ability to endure the weight of train cars, the impact of wheels, as well as the forces exerted during braking and acceleration. Moreover, steel rails provide stability and a smooth surface for the train's journey, ensuring the safety and efficiency of freight train operations. Furthermore, steel rails necessitate less maintenance in comparison to alternative materials, rendering them a cost-effective selection for freight train networks.

- Q:Can steel rails be used in underground or subway systems?

- Indeed, underground or subway systems can utilize steel rails. The reason behind the widespread use of steel rails in subway systems is their robustness, endurance, and capability to endure substantial weights. Consequently, they furnish trains with a sleek and steady path to traverse, guaranteeing secure and effective transportation. Moreover, steel rails can be effortlessly upheld and substituted as needed, rendering them the favored option for subterranean railway systems.

- Q:Why is the thermit reaction welded to rails instead of welded rails?

- Steel contains other added elements, while the thermit reaction produces only iron.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Light Steel Rail for MIne Orbits GB9kg GB12kg GB15kg

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords